Composite film for candy packaging and preparation method thereof

A composite film and candy technology, used in packaging, wrapping paper, transportation and packaging, etc., can solve problems such as difficulty in stably satisfying instant heat sealing, difficulty in imparting stiffness to candy packaging, and poor flatness due to PE film.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] Correspondingly, the present invention also provides a preparation method of the above-mentioned candy packaging composite film, comprising the following steps:

[0034]a. Extrude the outer layer resin, the core layer resin and the inner layer resin at 210°C to 250°C, then cast, cool and shape the film to obtain a film including the outer layer, core layer and inner layer in sequence, and the outer layer of the film Corona treatment is carried out to obtain a cast polypropylene film including a corona layer, a core layer and an inner layer in sequence; the inner layer resin includes: 97wt% to 99wt% metallocene terpolymer polypropylene and 1wt% to 3wt% opening agent;

[0035] B, carrying out plasma surface treatment to the corona layer of the cast polypropylene film, and vacuum aluminum plating to obtain the aluminum-coated cast polypropylene film;

[0036] c. Composite the polyethylene terephthalate film and the aluminized cast polypropylene film by a dry compounding m...

Embodiment 1

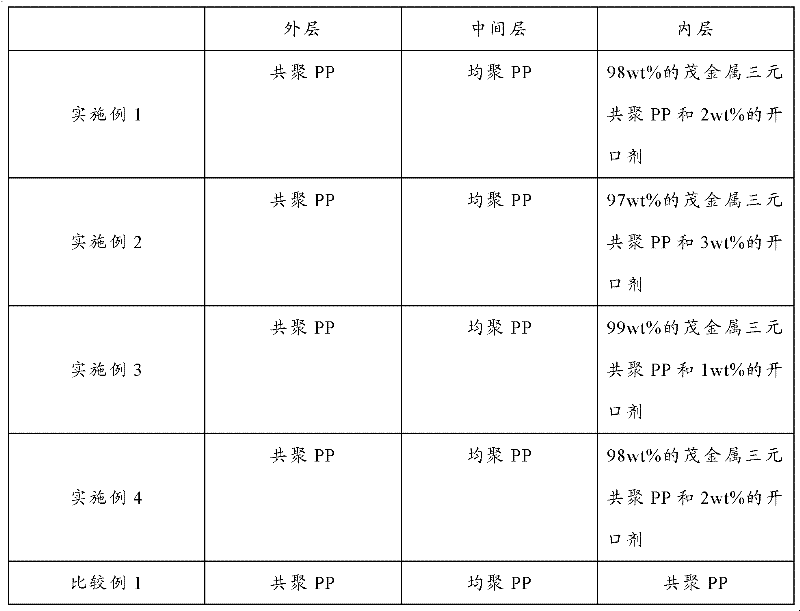

[0051] 1. Add the outer layer resin raw material, middle layer resin raw material and inner layer resin raw material respectively to the three barrels of the co-extrusion machine. The resin raw material formula of each layer is listed in Table 1;

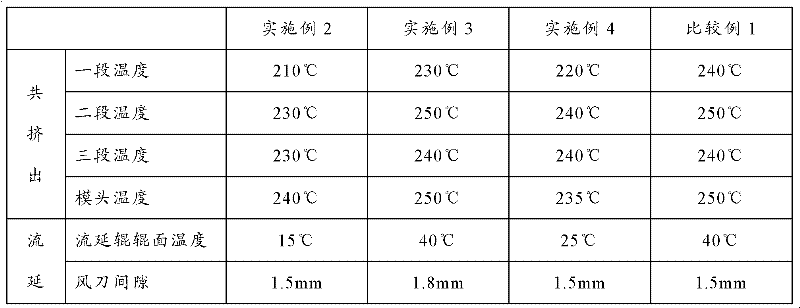

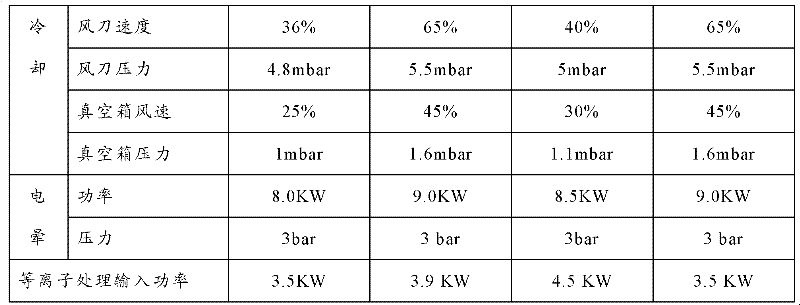

[0052] The raw materials in the three barrels are co-extruded and then enter the casting station to cool and shape. Temperature: 245° C.; the surface temperature of the casting roll is set at 30° C. in the casting process. Air knife clearance: 1.2mm; air knife speed: 50%; vacuum box wind speed: 35%; air knife pressure: 5.2mbar; vacuum box pressure: 1.2mbar.

[0053] Carry out corona treatment on the outer surface of the cast film after corona treatment, set the corona treatment power to 8.5KW, and the corona roller pressure to 3bar. After corona treatment, a paper packaging CPP film is obtained. The thickness ratio of the halo layer, the middle layer and the inner layer is 5:18:7.

[0054] 2. Place the CPP film prepared in step 1 ...

Embodiment 2~ Embodiment 4

[0058] The preparation process of the composite film for candy packaging in the above-mentioned embodiment is the same as that in Example 1. The raw material formula of the VMCPP film is listed in Table 1, and the process parameters are listed in Table 2.

[0059] The thickness of the PET film prepared by the above two examples is 12 μm, the thickness of the CPP film is 30 μm, and the thickness of the aluminum-coated layer is 400 angstroms;

[0060] Wherein, the thickness ratio of the film outer layer, middle layer and inner layer of the CPP film prepared in embodiment 2 is 5: 17.5: 7.5;

[0061] The thickness ratio of the film outer layer of the CPP film that embodiment 3 prepares, middle layer and inner layer is 5: 19: 6;

[0062] The thickness ratio of the film outer layer, middle layer and inner layer of the CPP film prepared in Example 4 is 5:18:7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com