Coated paper and production method thereof

A production process and technology of coated paper, applied in paper/cardboard layered products, papermaking, paper coatings, etc., can solve the problems of poor permeability, poor barrier performance and sealing performance, and inconvenient use.

Inactive Publication Date: 2018-11-30

福建益百利包装材料有限公司

View PDF5 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The applicant found that the existing products have at least the following technical problems: 1. Poor permeability. When the coated paper material formed by PE coating film is used for oil-water penetration test, different degrees of permeation areas will appear at the joints. 2. The strength and toughness are poor. The existing products are the main production materials of instant noodle paper bowls. Instant noodles are generally fried food and equipped with oil packets. The corners of individual noodle blocks are affected by external forces. It is easy to pierce the PE layer, and the oil stain will penetrate to the outer surface when brewing instant noodles, making the product unsightly and posing a safety hazard

3. The composite fastness is poor, and it is prone to peeling or delamination. After the product with a cover is uncapped, the cover film and the PE film of the product body paper are easy to be torn off together, destroying the beauty of the product and the safety of use. ;4. The instant noodle paper bowl made of PE-coated film-coated paper usually prompts "do not microwave" in the font of the appearance printing part, which is extremely inconvenient to use.

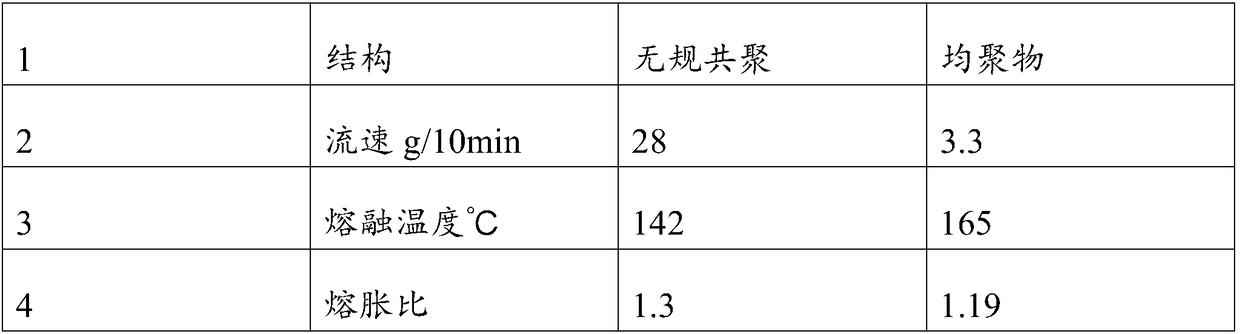

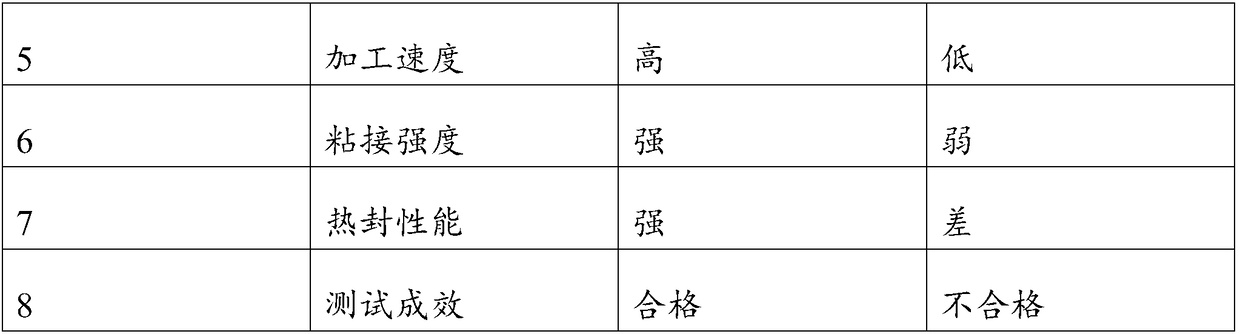

5. The coating layer of the existing material is milky white and opaque, and the printing appearance is affected; 6. In terms of the coating film process, the melting flow rate and coating speed of the existing PE material are slow, and the production efficiency is low

In addition, the production cost of products made of PE coated film is relatively high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment approach

[0036] According to a preferred embodiment of the present invention, the coating temperature of the coating machine is 320--325°C.

[0037] According to a preferred embodiment of the present invention, the base paper includes kraft paper, coated paper, white cardboard, white paper or cultural paper.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Login to View More

Abstract

The invention provides a coated paper and a production method thereof and relates to the technical field of packaging materials. The coated paper comprises a base paper and a coating film layer. The coating film layer coats the surface of the base paper. The coating film layer is prepared from a polypropylene material through coating and thus the coated paper has the advantages of good transparency, small shrinkage, low heat sealing temperature, high bonding strength, beautiful appearance, good waterproof performances, high strength, microwave heating and low cost.

Description

technical field [0001] The invention relates to the technical field of packaging materials, in particular to a high-temperature-resistant coated paper and a production process thereof. Background technique [0002] Currently used packaging paper is generally provided with a coating layer on either side of the cardboard or on both sides of the plane, and then processed into a paper container with a preset shape for holding hot water or ice water or hot food or dry food. Products, etc., the existing products all use traditional PE coating film or PE material. [0003] The applicant found that the existing products have at least the following technical problems: 1. Poor permeability. When the coated paper material formed by PE coating film is used for oil-water penetration test, different degrees of permeation areas will appear at the joints. 2. The strength and toughness are poor. The existing products are the main production materials of instant noodle paper bowls. Instant n...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): D21H19/00D21H19/84B32B27/10B32B27/32B32B29/00

CPCB32B27/10B32B27/32B32B29/002D21H19/00D21H19/84

Inventor 林荣杰朱向英胡盛强

Owner 福建益百利包装材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com