Easy-to-uncover aluminum-plastic cover film for cosmetic cover ring as well as production technology and application

A technology for cosmetics and aluminum-plastic caps, applied in applications, chemical instruments and methods, household components, etc., can solve problems such as uneven bonding strength, achieve uniform bonding force, avoid melting deformation, and make openings difficult

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the heat-sealing layer 3 in the present embodiment is as follows:

[0039] After the ethylene-propylene copolymer elastomer and PE are uniformly mixed in a mixer, a PE film is prepared by a film blowing method, and the heat-sealing layer 3 required in this embodiment is obtained.

[0040] The production process of the easy-to-remove aluminum-plastic cover film used for the cosmetic cover ring in this embodiment is as follows:

[0041] (A) Coating the adhesive on one side of the aluminum foil layer 2 on a dry lamination machine, drying the solvent to obtain an outer adhesive layer, and pressing the outer layer 1 by a composite roll to obtain a composite aluminum foil layer 2;

[0042] (B) After coating the adhesive again on the aluminum foil surface of the composite aluminum foil layer 2, the solvent is dried to obtain the outer adhesive layer, and the outer adhesive layer is facing the heat-sealing layer 3, and pressed by a composite roller to ob...

Embodiment 1

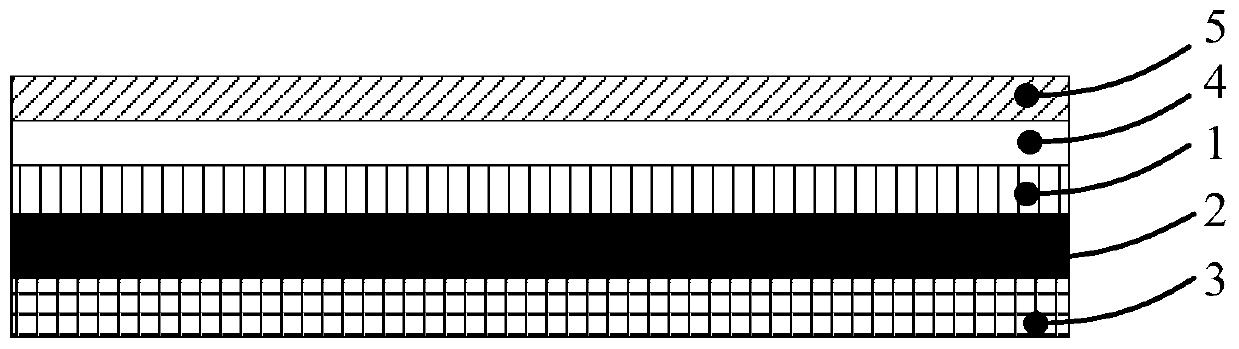

[0049] An easy-to-remove aluminum-plastic cover film for cosmetic cover rings in this embodiment includes an outer layer 1, an aluminum foil layer 2 and a heat-sealing layer 3, and the outer layer 1 and the heat-sealing layer 3 are respectively arranged on the The upper and lower sides of the aluminum foil layer 2, the outer layer 1 and the aluminum foil layer 2, and the aluminum foil layer 2 and the heat-sealing layer 3 are connected by an adhesive, and the outer layer 1 is 12 μm PET film layer, the aluminum foil layer 2 is 50 μm aluminum foil, the thickness of the heat-sealing layer 3 is 40 μm, and the adhesive is solvent-based polyurethane glue.

[0050] In this embodiment, the PET film is Hangzhou Dahua Plastic Industry Co., Ltd.; the aluminum foil layer 2 is an O-state aluminum foil, and the 8011 aluminum foil produced by Xiamen Xiashun Aluminum Foil Co., Ltd. is selected.

[0051] The heat-sealing layer 3 in the present embodiment is made up of 80wt% ethylene-propylene c...

Embodiment 2

[0061] An easy-to-remove aluminum-plastic cover film for cosmetic cover rings in this embodiment includes an outer layer 1, an aluminum foil layer 2 and a heat-sealing layer 3, and the outer layer 1 and the heat-sealing layer 3 are respectively arranged on the The upper and lower sides of the aluminum foil layer 2, the outer layer 1 and the aluminum foil layer 2, and the aluminum foil layer 2 and the heat-sealing layer 3 are connected by an adhesive, and the outer layer 1 is 30 μm PET film layer, the aluminum foil layer 2 is 40μm aluminum foil, the thickness of the heat-sealing layer 3 is 50μm, and the adhesive is solvent-based polyurethane glue.

[0062] In this embodiment, the PET film is Hangzhou Dahua Plastic Industry Co., Ltd.; the aluminum foil layer 2 is O-state aluminum foil, which is 8021 aluminum foil produced by Chinalco Aluminum Foil Co., Ltd.

[0063] The heat-sealing layer 3 is made up of 65wt% ethylene-propylene copolymer elastomer and 35wt% PE, and PE in the pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coating thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com