Multilayer frozen polyethylene film

A polyethylene film and polyethylene technology, applied in the field of packaging materials, can solve the problems of unsafe transportation and easy to be polluted, and achieve the effects of reliable and safe transportation, protection of sanitation and safety, heat sealing speed and strong fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

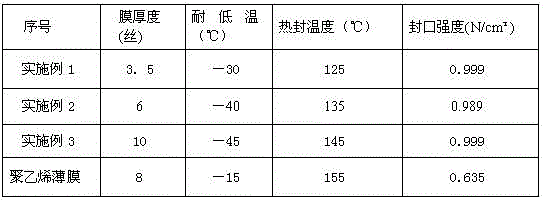

Examples

Embodiment 1

[0027] The weight percentages of selected raw materials are as follows:

[0028] Protective layer: low density polyethylene 60%, linear low density polyethylene 40%;

[0029] Temperature resistant layer: low density polyethylene 60%, chlorinated polyethylene 40%;

[0030] Heat seal layer: low density polyethylene 65%, chlorinated polyethylene 10%, metallocene linear low density polyethylene 25%.

[0031] Prepare the protective layer, temperature-resistant layer and heat-sealable layer according to the above ratio, and then put them into the hopper of each layer of the extruder in the film blowing machine. After heating, the die is extruded and blown by the die to cool and form and then pulled up. Then coiling, slitting and re-inspection, and finally inspection, packing and storage.

[0032]

Embodiment 2

[0034] The weight percentages of selected raw materials are as follows:

[0035] Protective layer: low density polyethylene 55% and linear low density polyethylene 45%;

[0036] Temperature resistant layer: low density polyethylene 60%, chlorinated polyethylene 40%;

[0037] Heat seal layer: low density polyethylene 65%, chlorinated polyethylene 10% and metallocene linear low density polyethylene 25%.

[0038] Prepare the protective layer, temperature-resistant layer and heat-sealable layer according to the above ratio, and then put them into the hopper of each layer of the extruder in the film blowing machine. After heating, the die is extruded and blown by the die to cool and form and then pulled up. Then coiling, slitting and re-inspection, and finally inspection, packing and storage.

[0039]

Embodiment 3

[0041] The weight percentages of selected raw materials are as follows:

[0042] Protective layer: low density polyethylene 65% and linear low density polyethylene 35%;

[0043] Temperature resistant layer: low density polyethylene 65%, chlorinated polyethylene 35%;

[0044] Heat seal layer: low density polyethylene 70%, chlorinated polyethylene 10% and metallocene linear low density polyethylene 20%.

[0045] Prepare the protective layer, temperature-resistant layer and heat-sealable layer according to the above ratio, and then put them into the hopper of each layer of the extruder in the film blowing machine. After heating, the die is extruded and blown by the die to cool and form and then pulled up. Then coiling, slitting and re-inspection, and finally inspection, packing and storage.

[0046]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com