Automatic film sealing machine for welding rods

A technology of sealing film machine and welding rod, which is applied in the directions of packaging sealing/fastening, packaging/bundling items, external support, etc., which can solve the problems of poor appearance quality at the sealing part, unguaranteed moisture-proof performance, and manpower occupation, etc., and achieve improvement. Moisture-proof performance, improving the quality of outer packaging, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

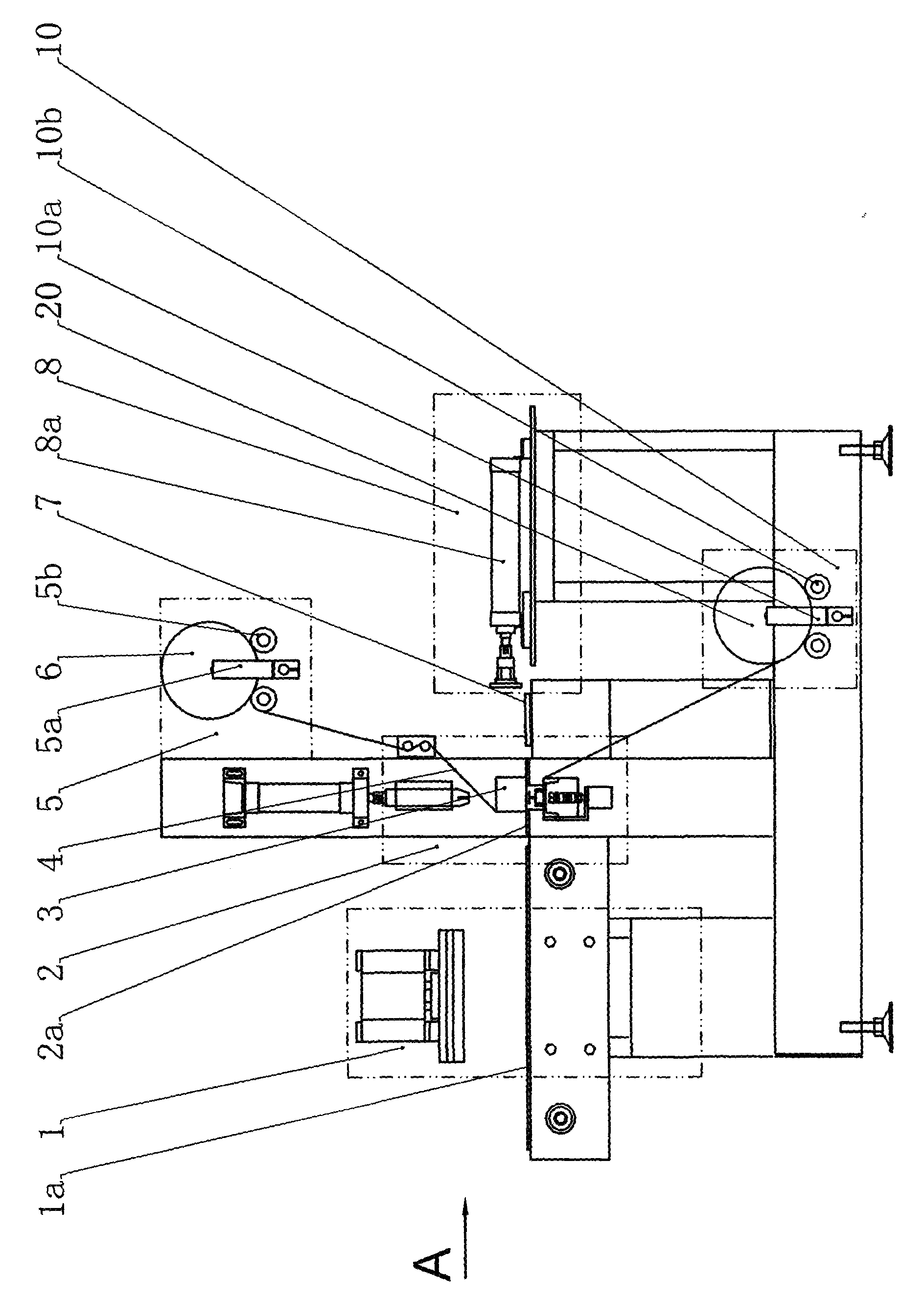

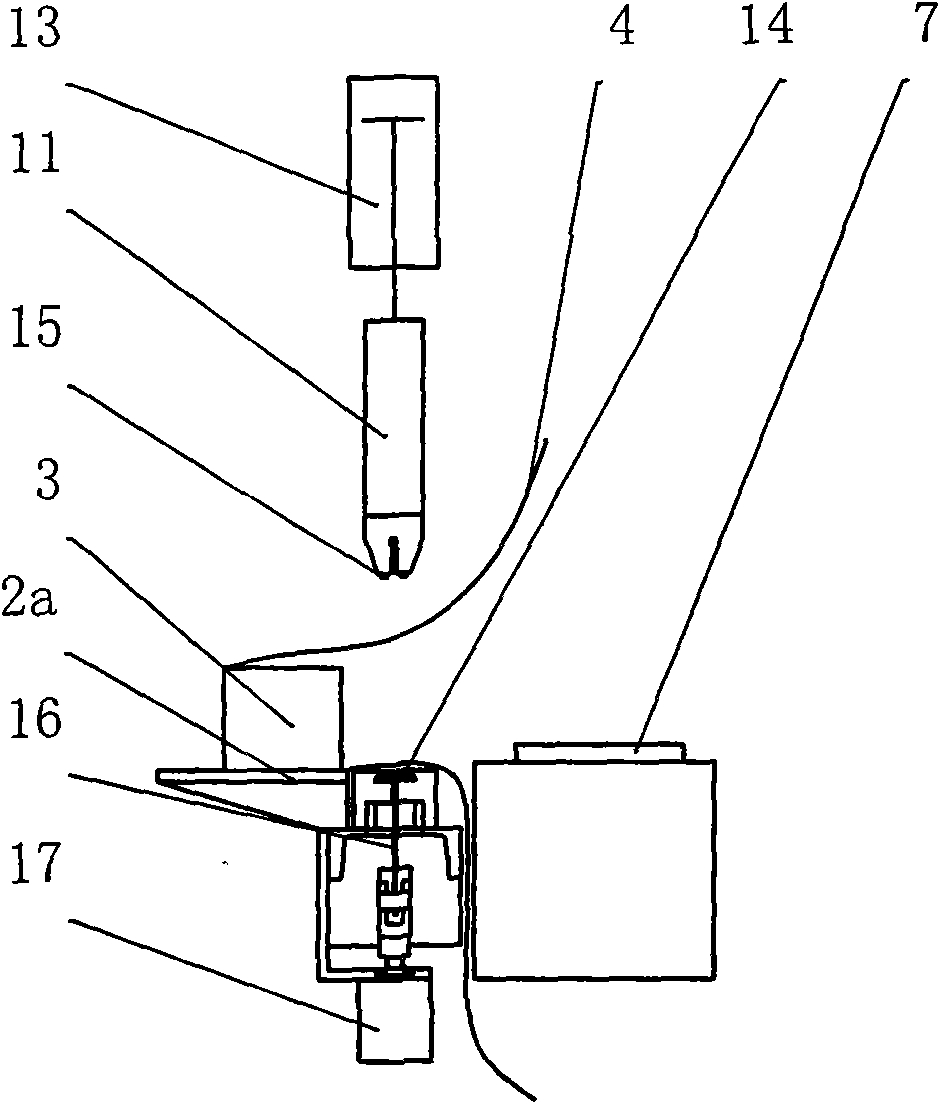

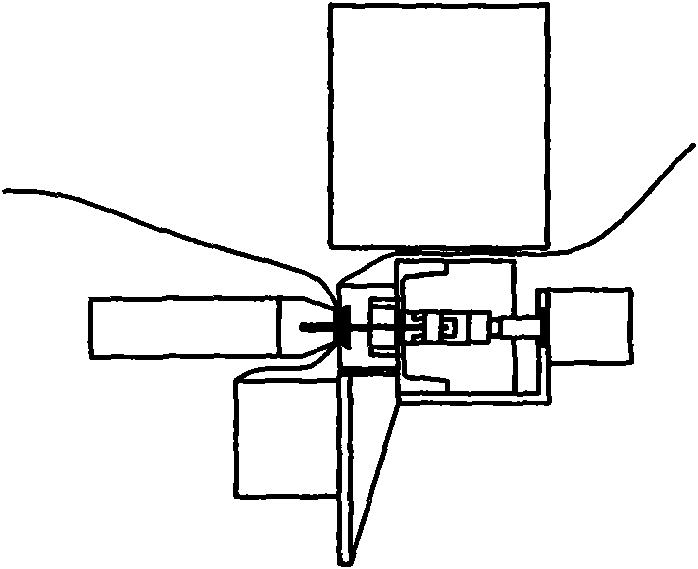

[0017] figure 1 It is a structural schematic diagram of the present invention; Figure 2 to Figure 4 It is a schematic diagram of the working process of the automatic film sealing of the present invention; Figure 5 yes figure 1 The view from direction A in the middle shows the schematic diagram of the end-sealing mechanism.

[0018] The present invention provides an automatic sealing film machine for welding rods. The automatic sealing film machine for welding rods includes: a conveyor belt 7 for transporting welding rod packaging boxes 3, an upper film feeding mechanism 5 equipped with an upper roll film 6, a lower roll film 20 equipped with Film feeding mechanism 10 , side sealing film mechanism 2 , end sealing mechanism 1 , and material pushing mechanism 8 .

[0019] Such as figure 1 As shown, a pusher mechanism 8 is provided on the right side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com