Heat pipe vacuum sealing method and apparatus thereof

A vacuum sealing and vacuum sealing technology, which is applied in the direction of hollow objects, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of unguaranteed heat pipe packaging quality, waste of materials in the packaging form, and influence on the use of heat pipes, and achieve simple structure and improved efficiency. Improvement in productivity and packaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

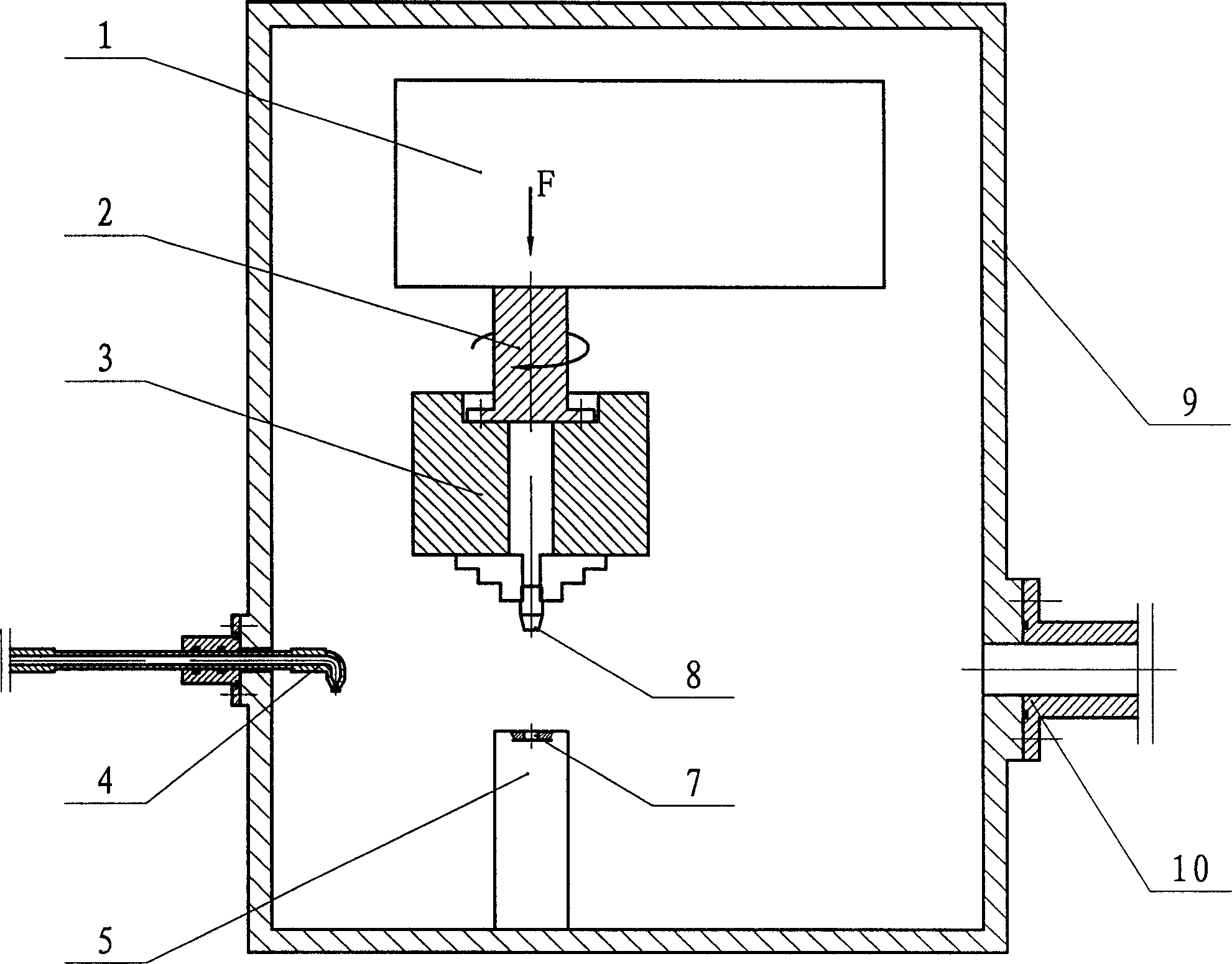

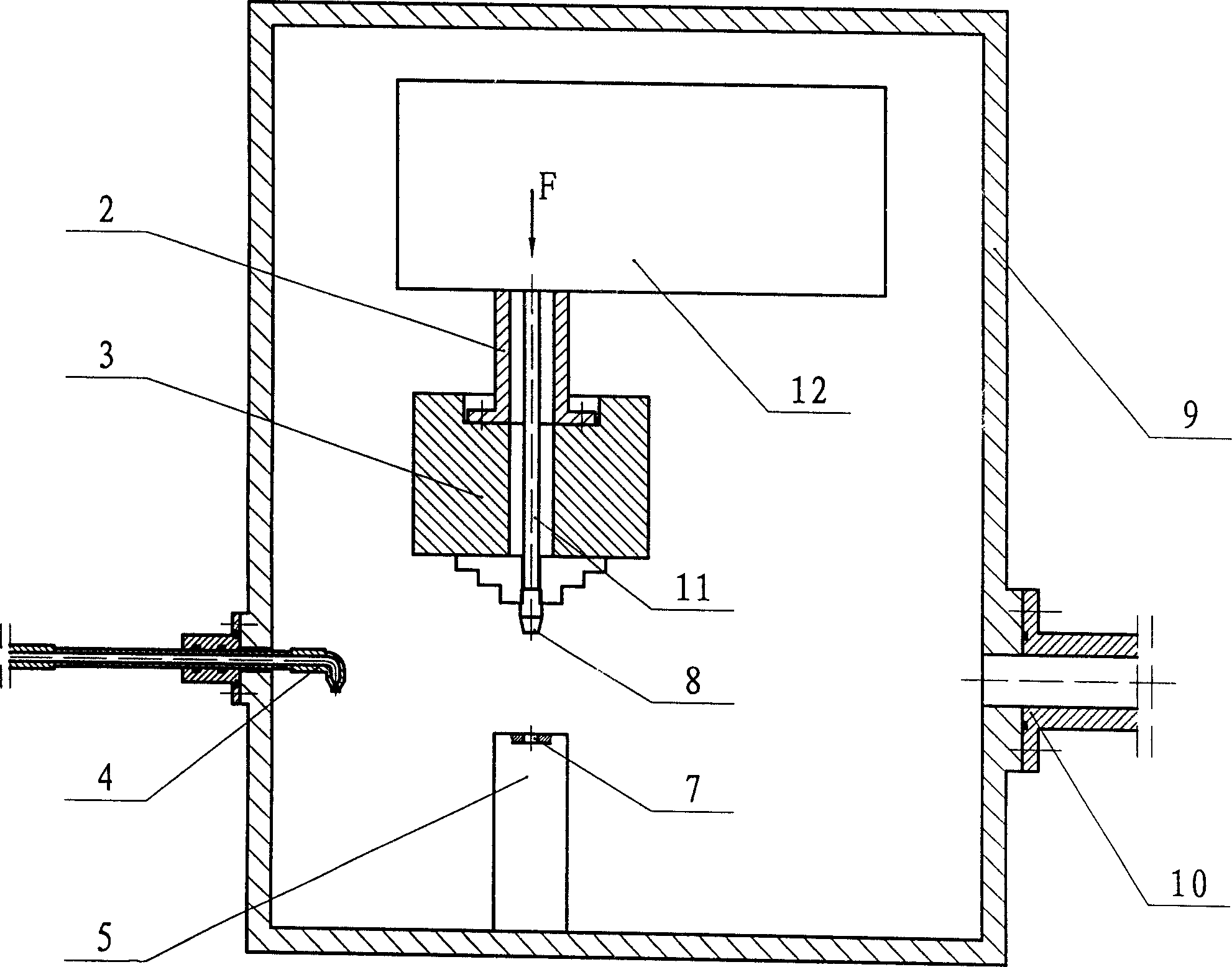

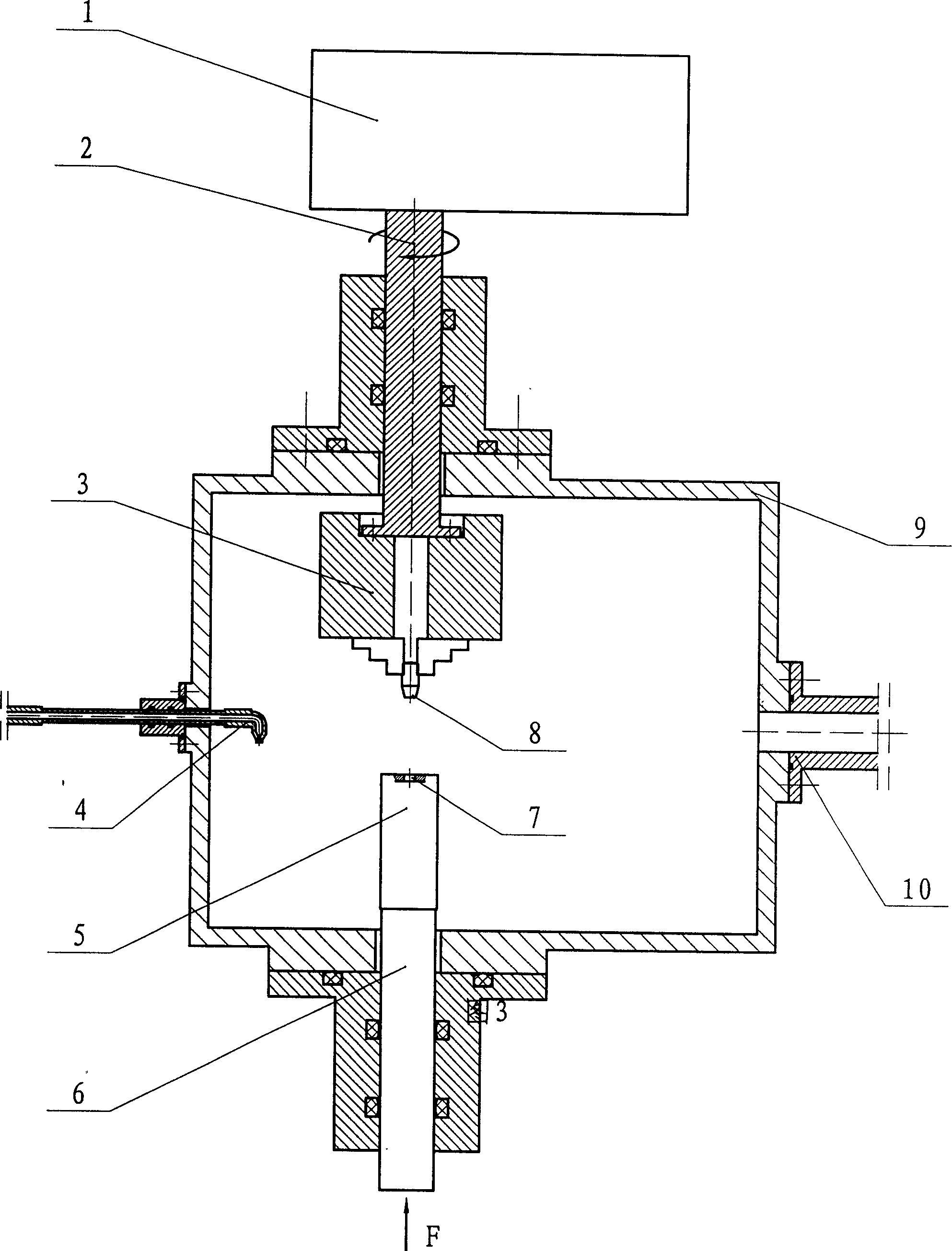

[0021] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0022] A heat pipe vacuum sealing method, the heat pipe to be packaged reserves a sealing hole 7, completes the process of vacuuming and liquid filling in a vacuum chamber 9, and applies friction welding 1 or ultrasonic welding 12 to weld the sealing plug 8 to the reserved sealing 7 and form a tight weld.

[0023] The sealing plug 8 may be one of a cylinder, a cone, a T-shaped body of revolution, and a body of revolution whose free end is smaller than the clamped end and whose generatrix transitions smoothly.

[0024] In the heat pipe vacuum sealing method described above, the reserved seal 7 may be one of a cylindrical hole, a conical hole, and a counterbore.

[0025] A heat pipe vacuum sealing device, including a vacuum generating system, a heat pipe to be packaged and its positioning and clamping system 5, a liquid filling system, a sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com