Automatic packaging process for winding thin film on steel coil

An automatic packaging and film technology, applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of low operation efficiency, long operation time, high labor intensity, etc., and achieve easy control, labor intensity reduction, and reasonable structure design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

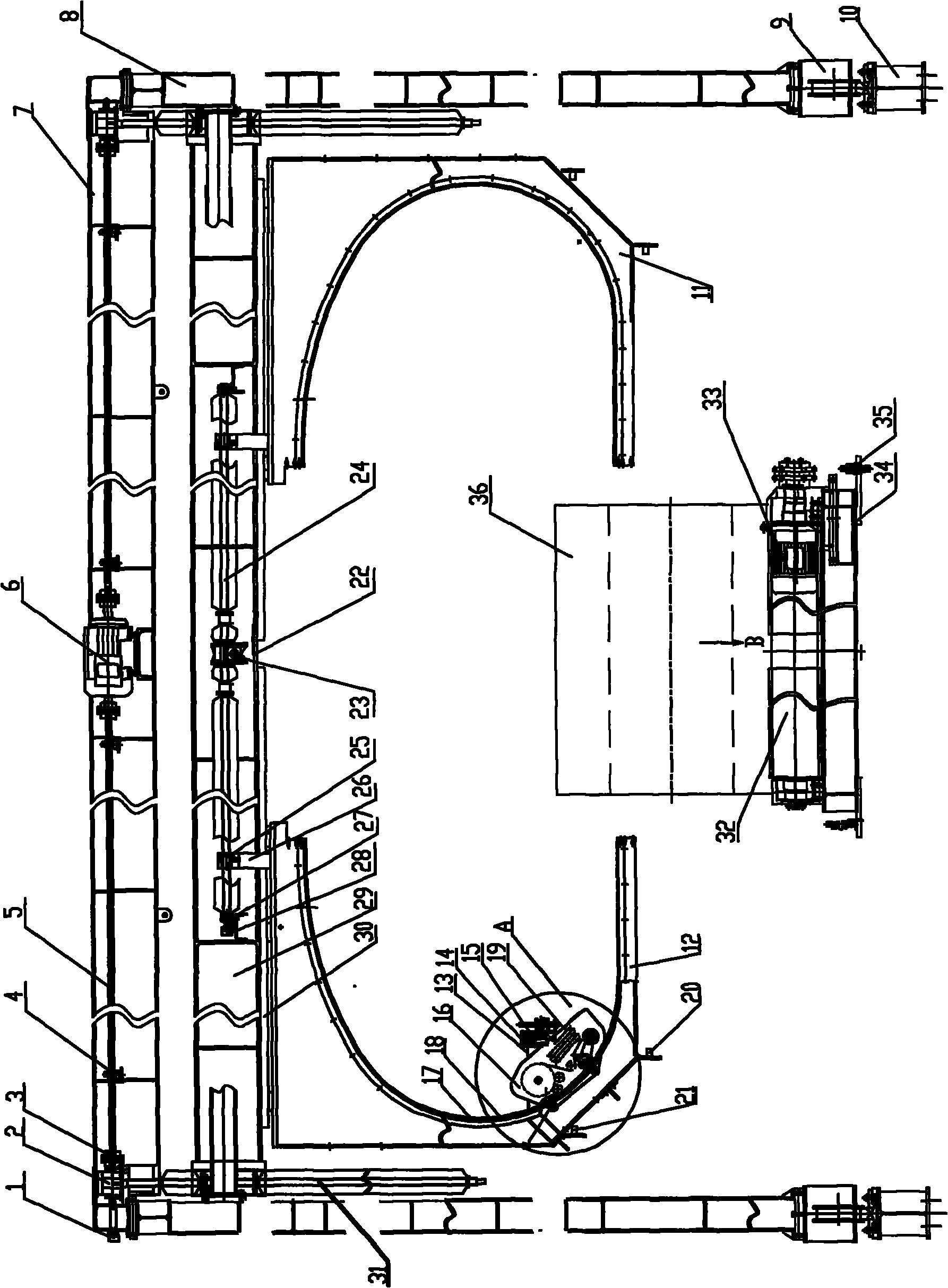

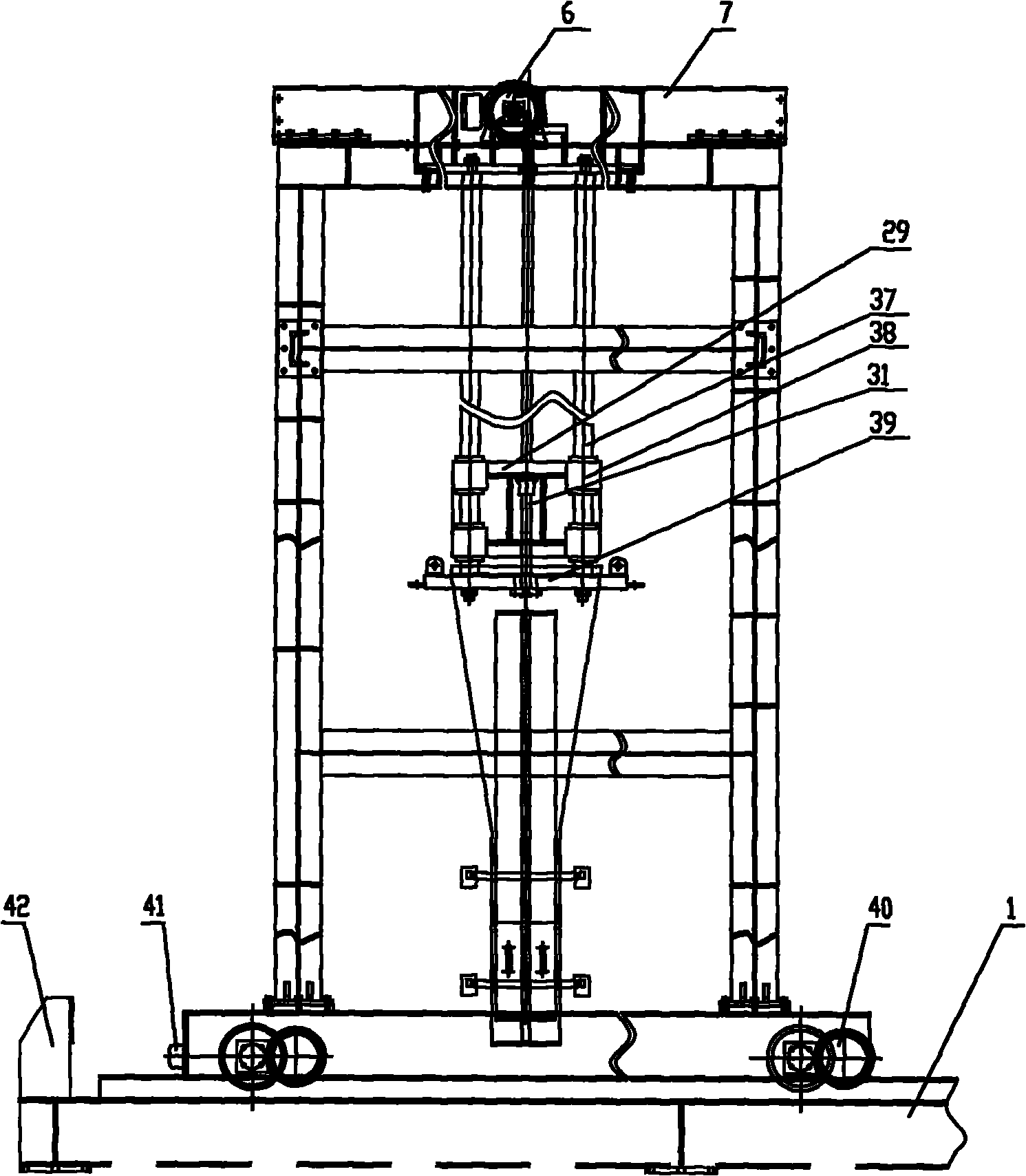

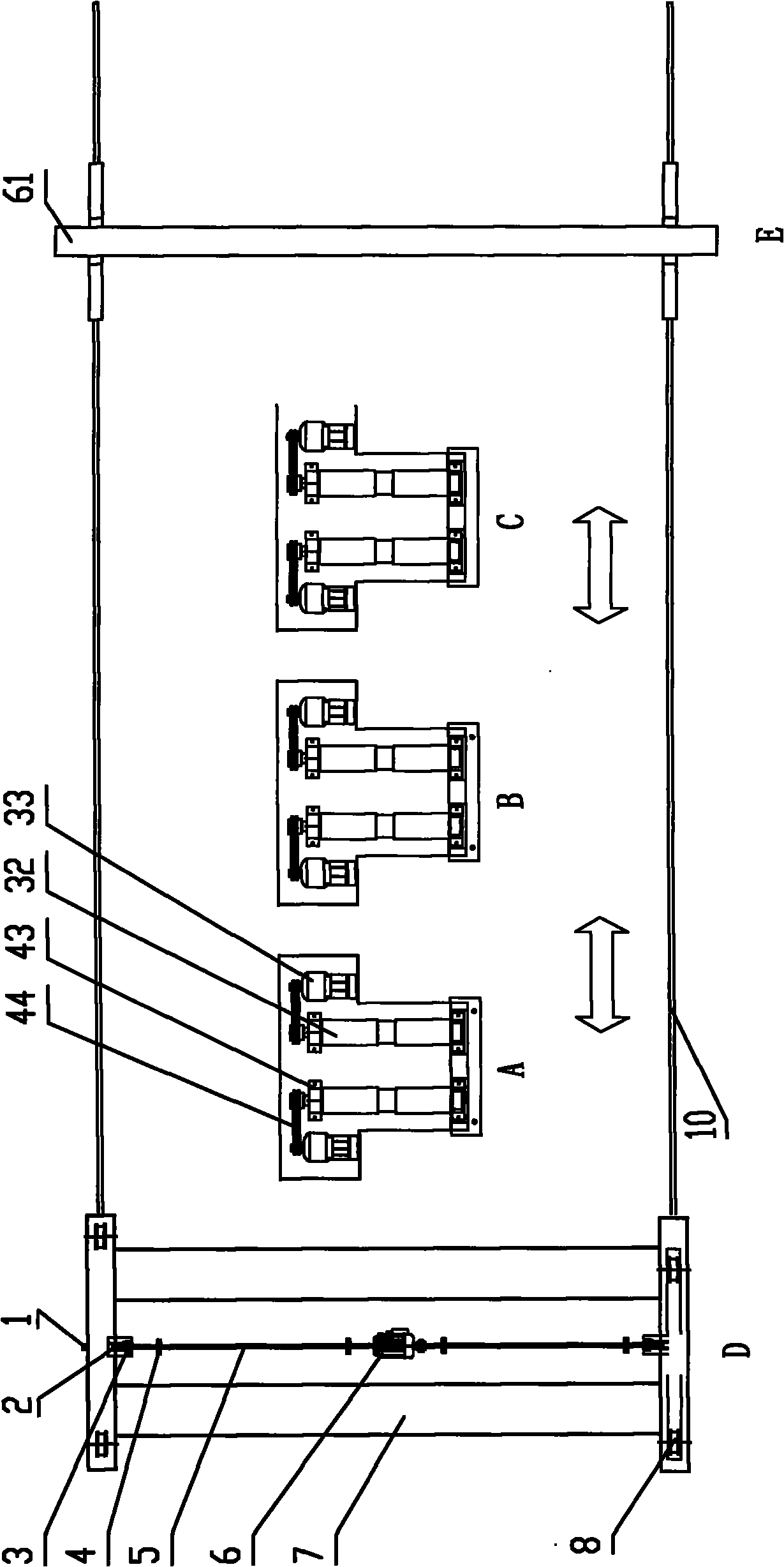

[0024] according to Figure 1-7 The specific structure of the present invention will be described in detail. The steel coil winding film automatic packaging process includes a crane 61 running on the track 10, an automatic film winding machine and a rolling machine for steel coil packaging, and an electrical control device with a PLC programmable control module as the core arranged on the console.

[0025] The automatic film winding machine for steel coil packaging used in this process includes two main frames 8 traveling on rails 10, the main frame connecting beam 7 and the wrapping mechanism arranged on the main frame connecting beam 7, film sports car 16 and electrical control Devices etc. Wherein the main frame mobile base 9 with rollers is assembled at the bottom of two main frame connecting cross 8, the main frame mobile motor 40 that is fixed on the main frame mobile base 9 drives the rollers to rotate, so that the main frame 8 and its main frame are connected The wra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com