Packaging case

a packaging case and case body technology, applied in the field of packaging cases, can solve the problems of high material cost, achieve the effects of reducing material cost and transportation cost, effective preventing cracks, and thin thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

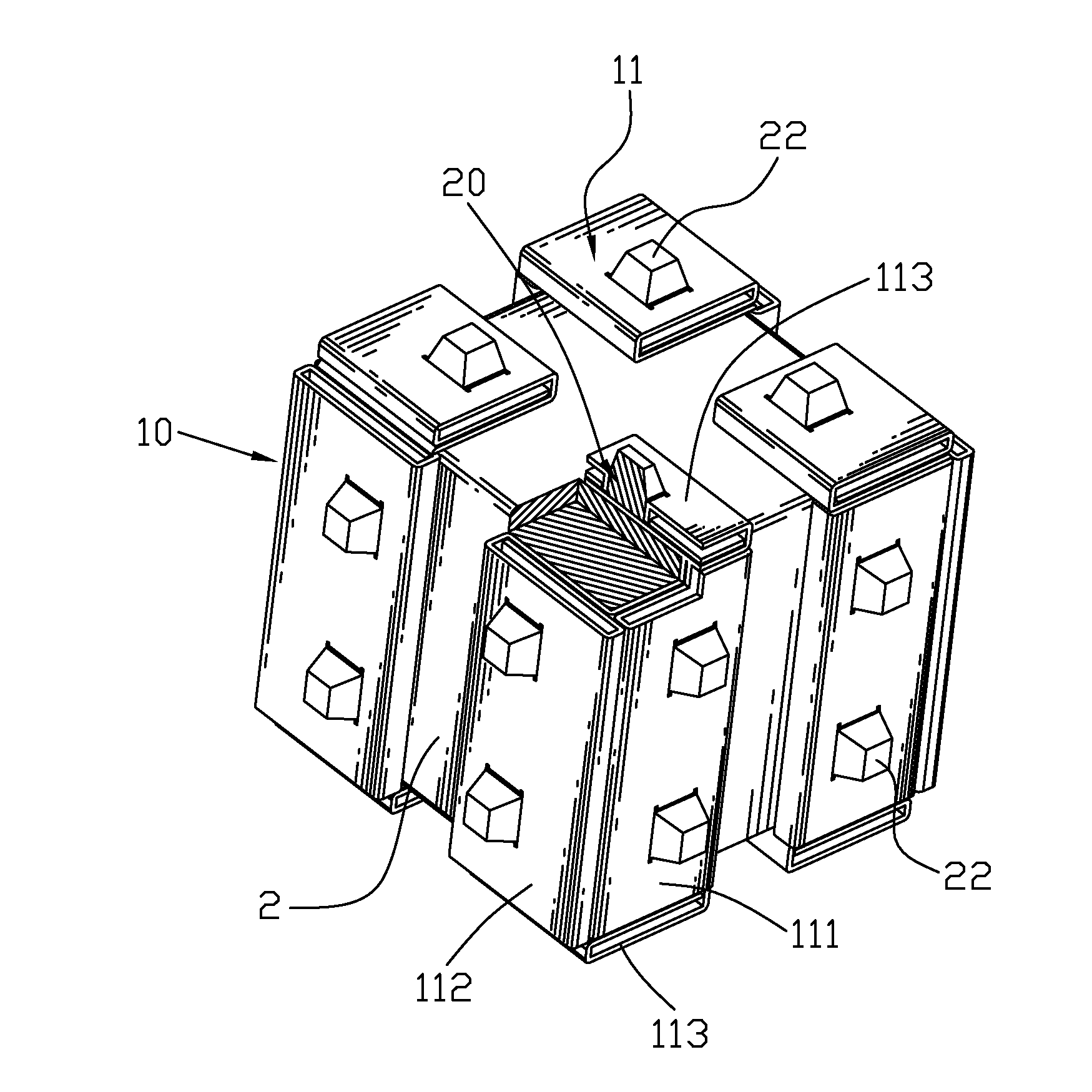

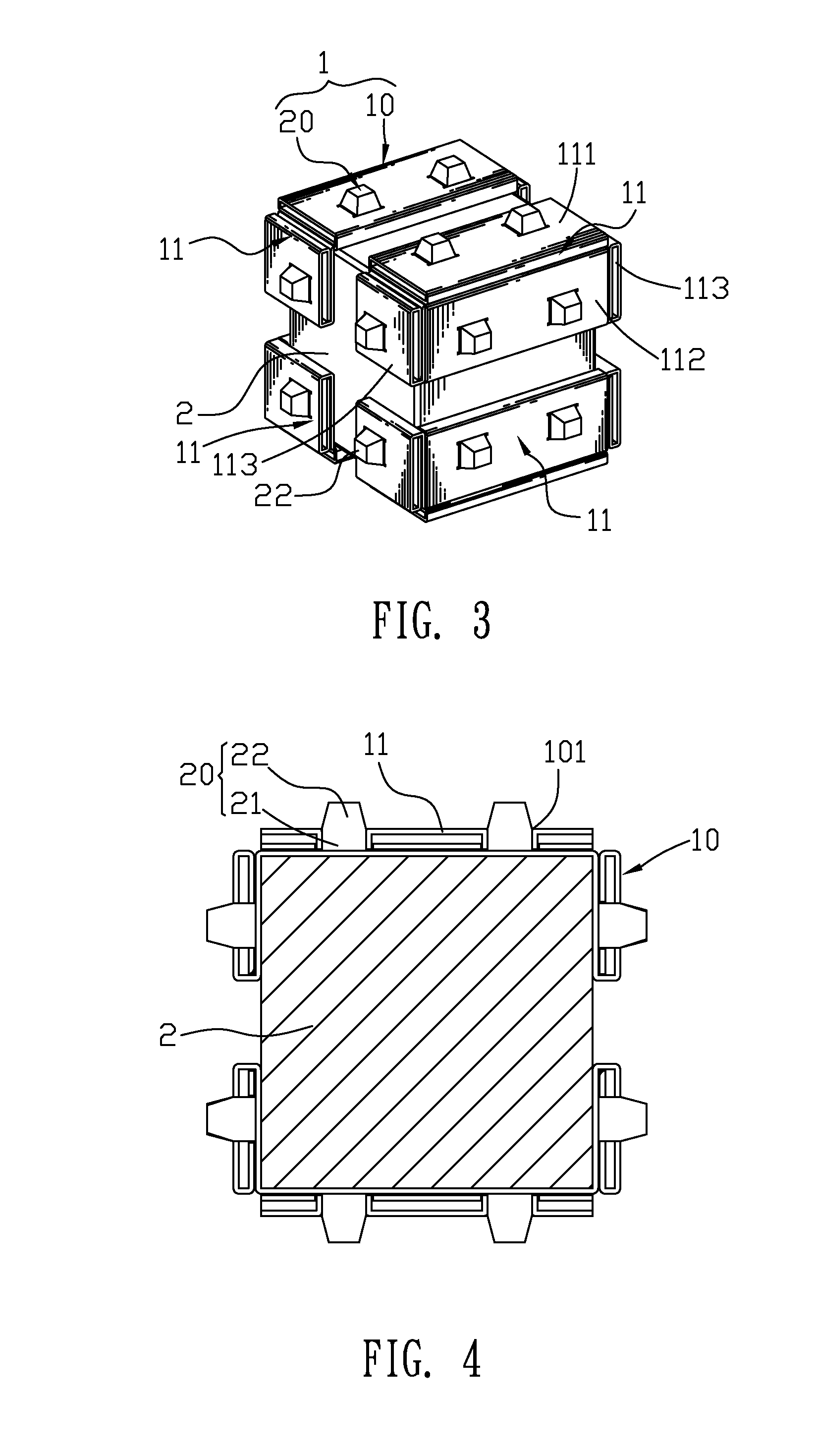

[0014]With reference to FIG. 3 and FIG. 4, a packaging case 1 in accordance with the present invention is shown. The packaging case 1 adapted for packing a cubic article 2 includes a fastening shell 10 and a plurality of buffering elements 20.

[0015]Referring to FIG. 3, FIG. 4 and FIG. 5, the fastening shell 10 is divided into four shells 11. Each shell 11 has a rectangular first wall 111, a rectangular second wall 112 perpendicular to the first wall 111, and two square third walls 113 connecting with the first wall 111 and the second wall 112. A receiving space (not shown) is accordingly formed among the first wall 111, the second wall 112 and the two third walls 113. Each of the first wall 111, the second wall 112 and the two third walls 113 defines at least one insertion hole 101.

[0016]Referring to FIG. 5, the fastening shell 10 is preferably made of a hollow sandwich material so as to lower a material cost and make the fastening shell 10 lighter for facilitating the fastening she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com