Gravel flushing device for constructional engineering

A technology of construction engineering and flushing device, which is applied in the field of construction engineering, can solve the problems affecting the construction effect and the quality of concrete, and achieve the effects of improving work efficiency and effect, simple structure, and reducing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

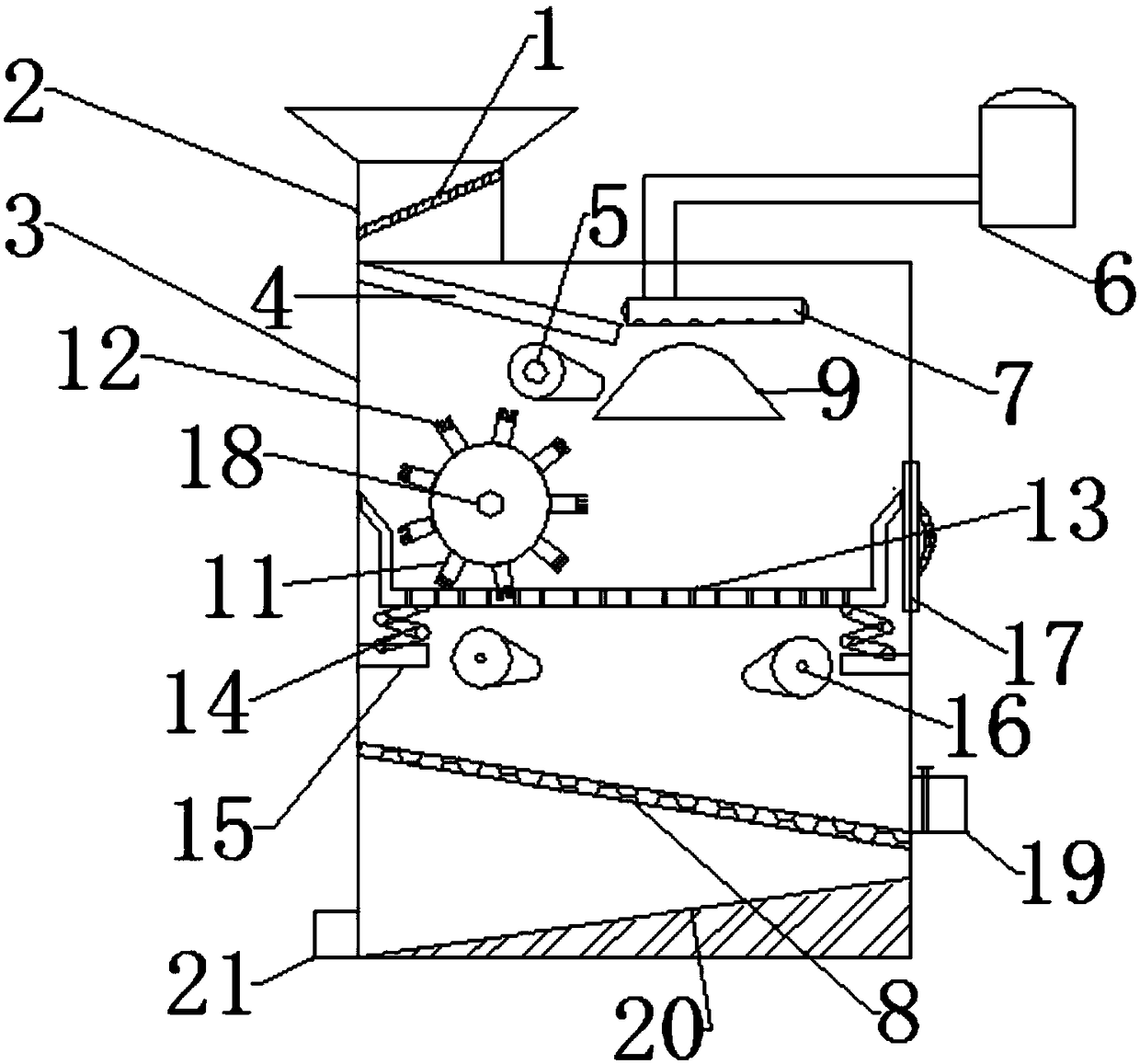

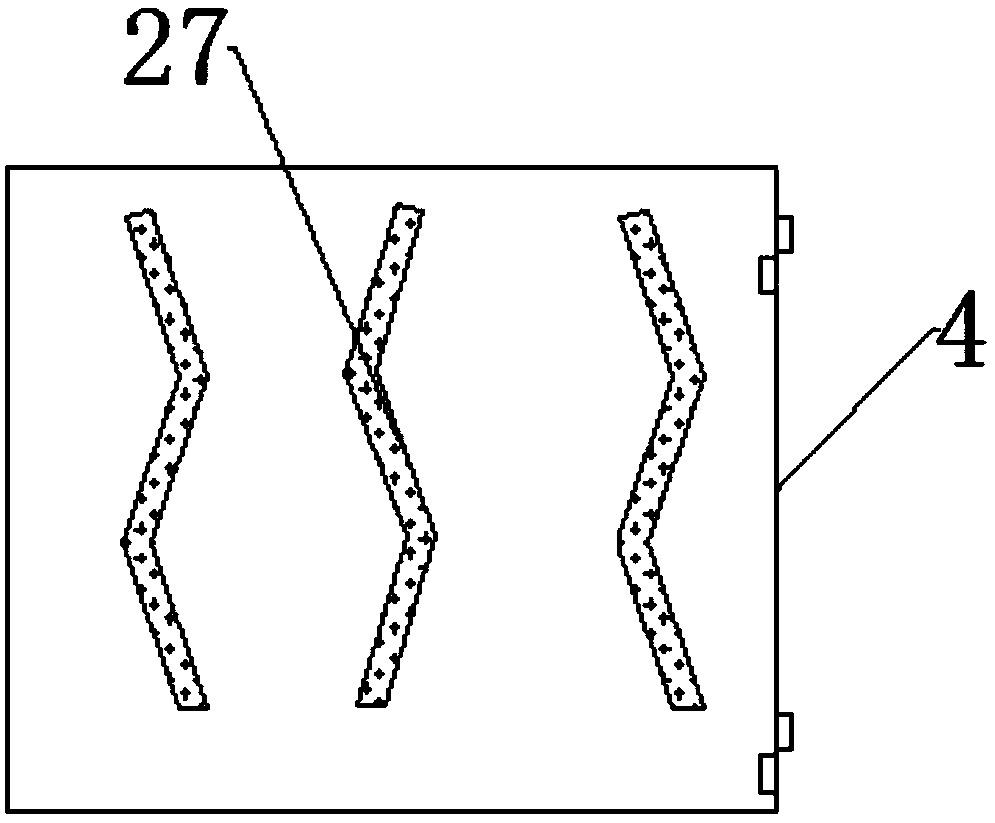

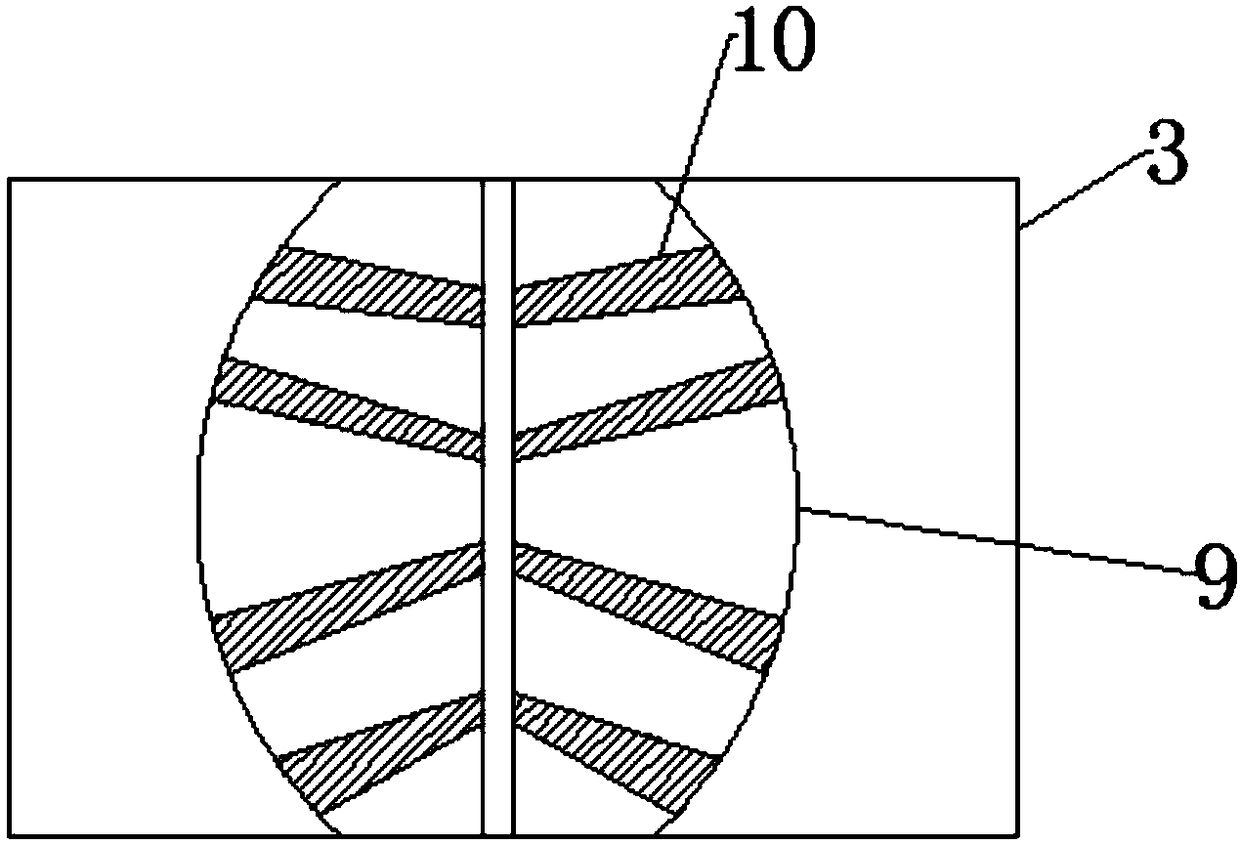

[0020] See Figure 1-5 , A construction engineering sand and gravel washing device, including grating 1, sand inlet pipe 2, screening box 3, feeding plate 4, water spray tank 6, spray drain 7, water filter membrane 8, table board 9, and sand slide groove 10. Scraper 11, brush 12, vibrating screen basket 13, spring 14, rotating drum 18 and water outlet pipe 21. The top of the screening box 3 is provided with a sand inlet pipe 2, and the sand inlet pipe 2 is inclined with a grille. 1. Through the grid 1, the branches and other large garbage in the sand are blocked and discharged, which is convenient to ensure the cleanness of the sand and the subsequent treatment. One side of the feeding plate 4 is hinged with the inner wall of the top of the screening box 3, and the other side of the feeding plate 4 is underneath. A first cam 5 is provided. The first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com