Processing technique and device of milled rice with embryo

A technology of germ rice and equipment, which is applied in the fields of grain degermination, grain treatment, grain pod removal, etc., can solve the problems of low germ retention rate and high energy consumption, and achieve the effects of uniform feeding, low energy consumption and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with drawings and embodiments.

[0032] With reference to accompanying drawing, the processing technology embodiment of germ rice of the present invention comprises the following steps:

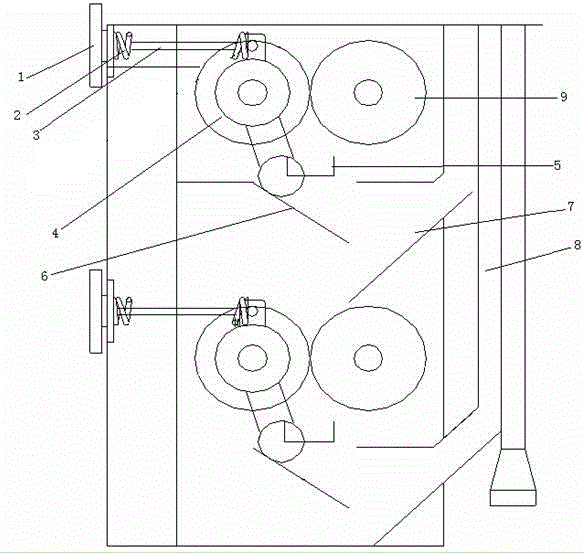

[0033] (1) Paddy feeding: Utilize the leveling plate 11 with V-shaped grooves on the sorting vibrating feeder 12, and sort the rice one by one into the hulling device;

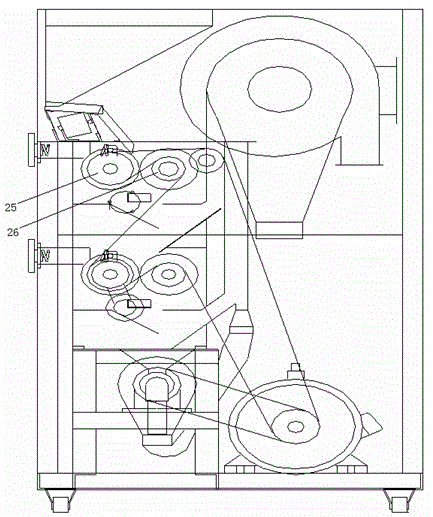

[0034] (2) First husking: the rice evenly sorted in step (1) enters the first husking device for husking;

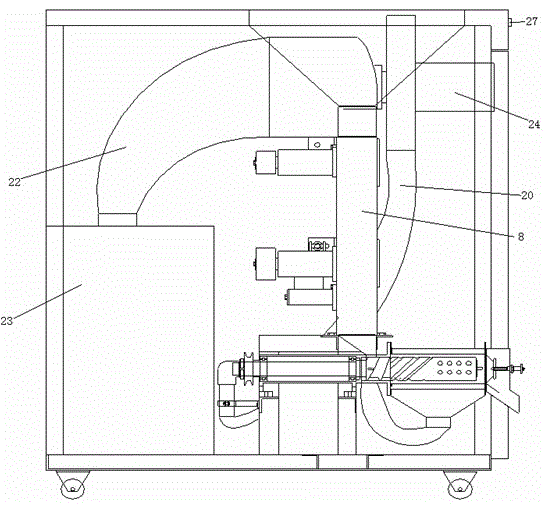

[0035] (3) The first sorting: sort the grains, brown rice and husks after the first hulling in step (2), so that the husks are discharged into the sedimentation box 23 connected with the Shacron 22 through the rice bran discharge channel 8 , sort out grain and brown rice;

[0036] (4) The second hulling: after step (2) the first sorting, the grain and brown rice enter the second hulling device for hulling;

[0037] (5) Second sorting: Sorting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com