A pole piece coating method and coating nozzle

A coating method and pole piece technology, which is applied to the surface coating liquid device, coating, electrode manufacturing, etc., can solve the problems of incomplete and accurate alignment of coatings, poor consistency of pole piece thickness, and increased processing difficulty, etc. , to achieve the effect of simple processing, improved production efficiency, and fast coating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

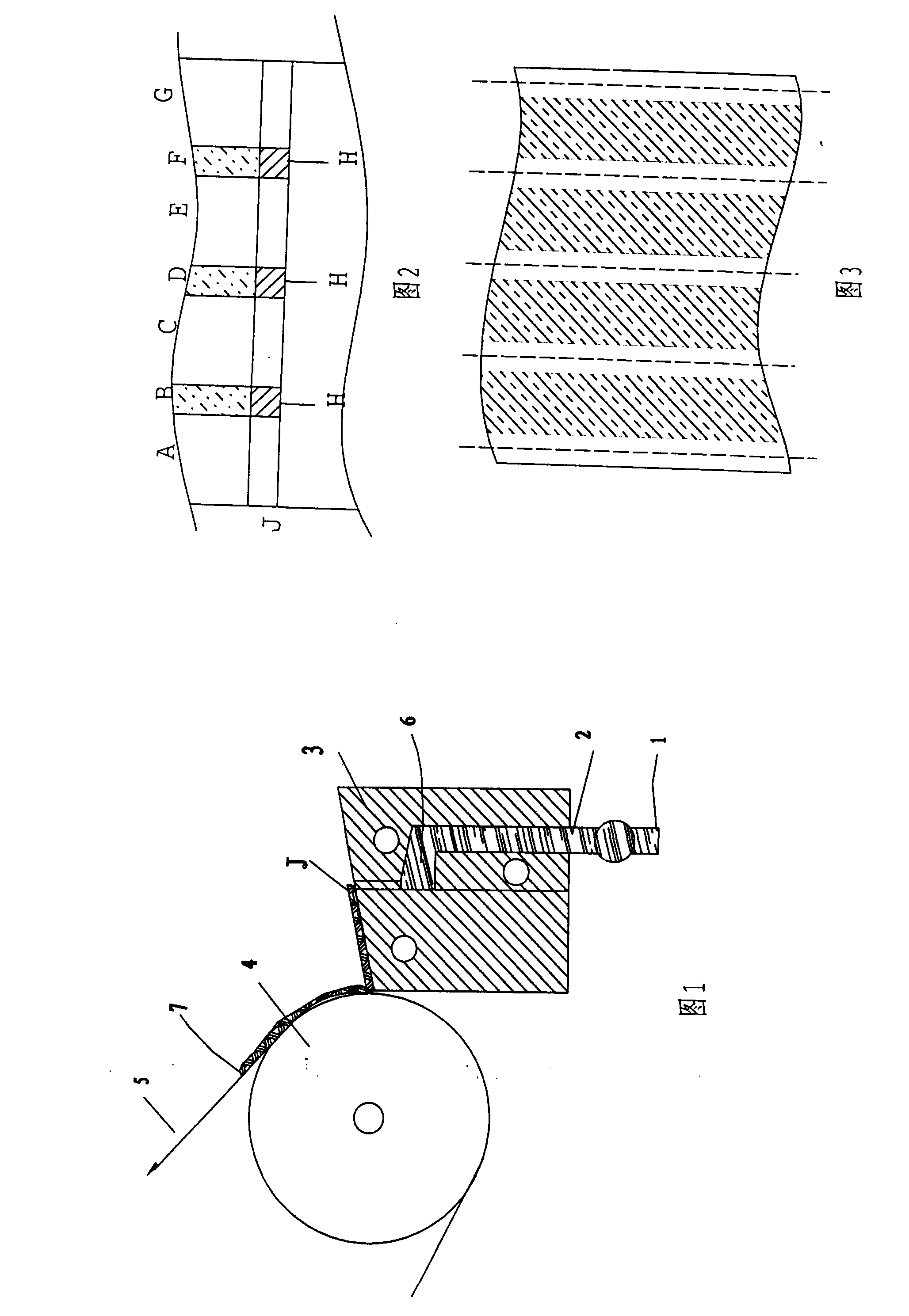

[0024] Figure 1 is a schematic diagram of the existing slope flow extrusion coating method. When performing the existing slope flow extrusion coating, as shown in Figure 1, the coating liquid 2 is transported from the feed pipe 1 into the coating head 3, The coating cavity 6 flows out from the coating nozzle gap J, flows downward along the slope of the coating nozzle gap J, reaches the lowest end of the coating nozzle and contacts the web 5 on the coating roller 4, and is taken away by the web 5, The cloth liquid 2 is spread on the web 5 to form a coating layer 7, and then dried, solidified and shaped to obtain the final product.

[0025] Hereinafter, the realization of the present invention will be described in detail by taking the front surface coating of the positive electrode sheet as an example.

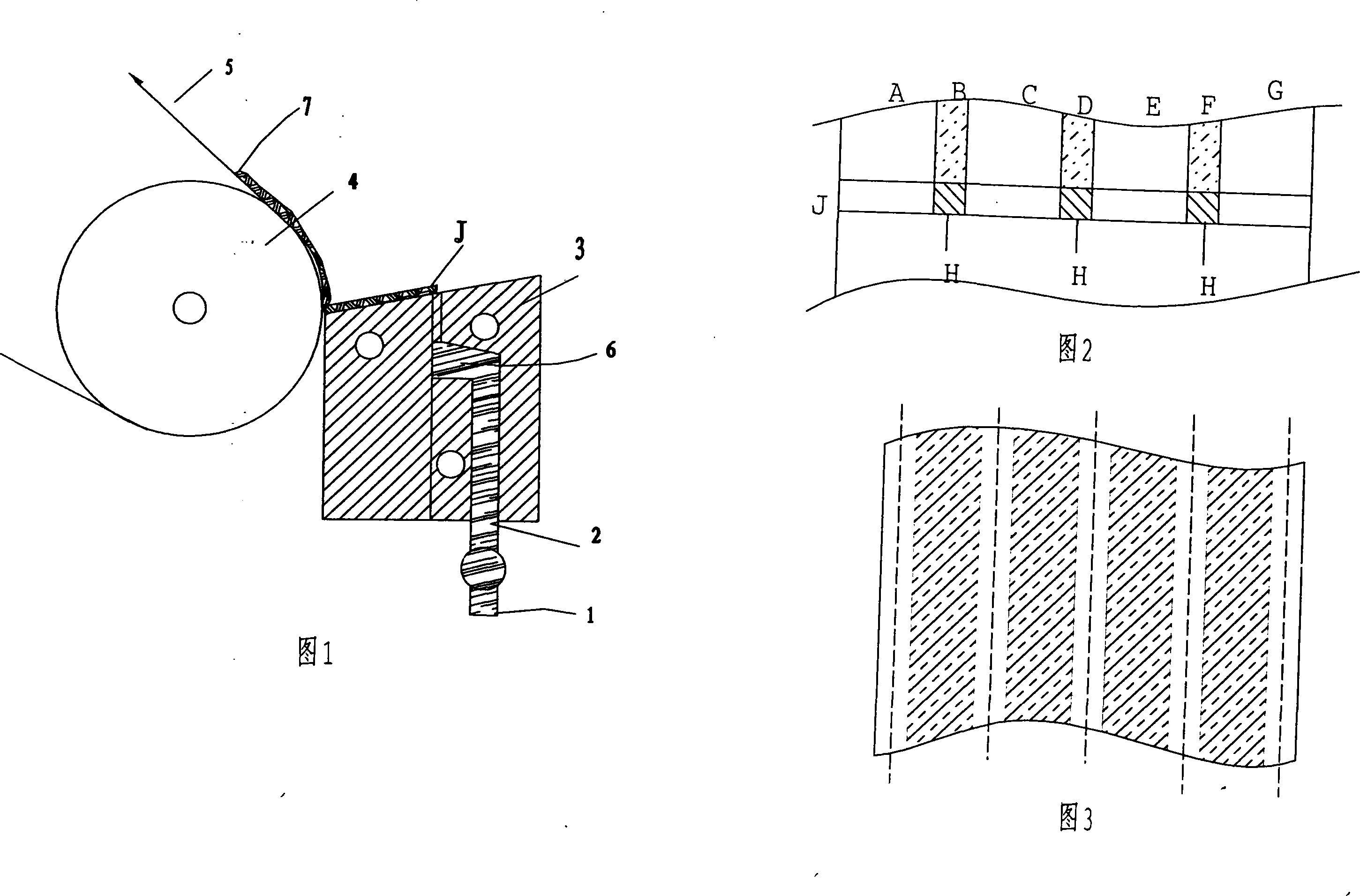

[0026] As shown in Figure 2, three closed plates H are set in the gap J of the slope extrusion coating nozzle. Sections A, C, E, and G are coating sections with a width of 115mm; se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com