Concrete production equipment

A production equipment and concrete technology, which is applied in the direction of clay preparation device, mixing operation control, mixing operation control device, etc. It can solve the problems of affecting the mixing quality, chaotic management of batching process records, waste of batching resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

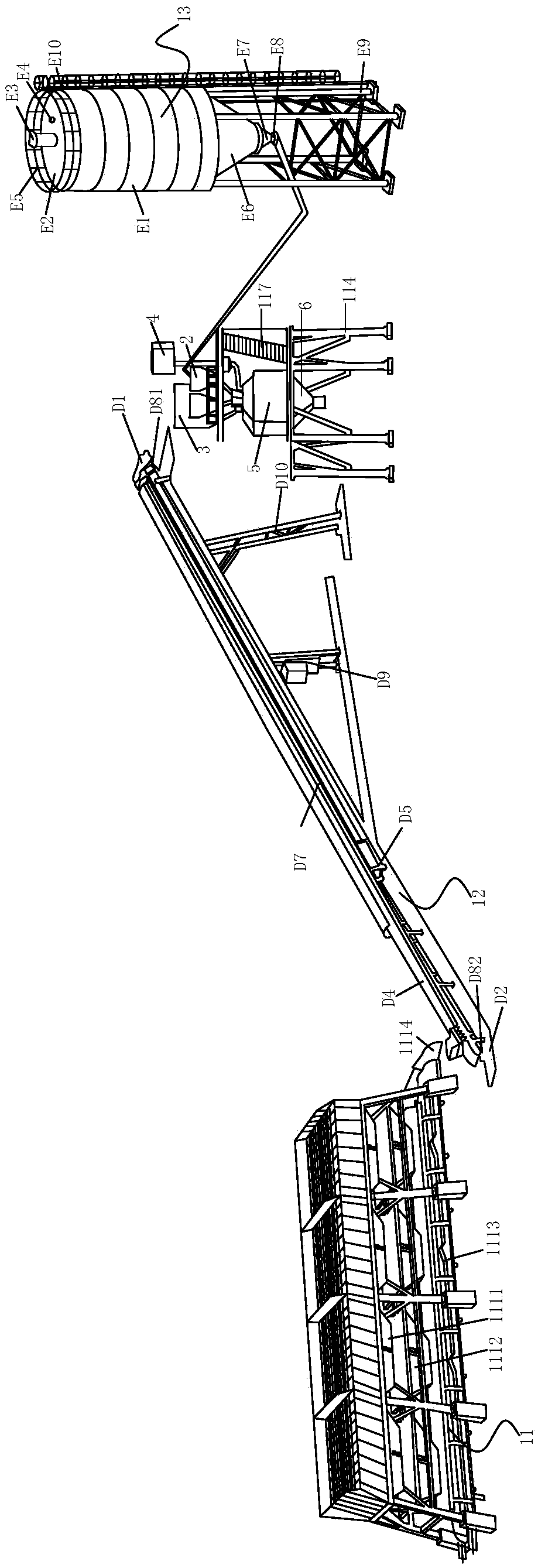

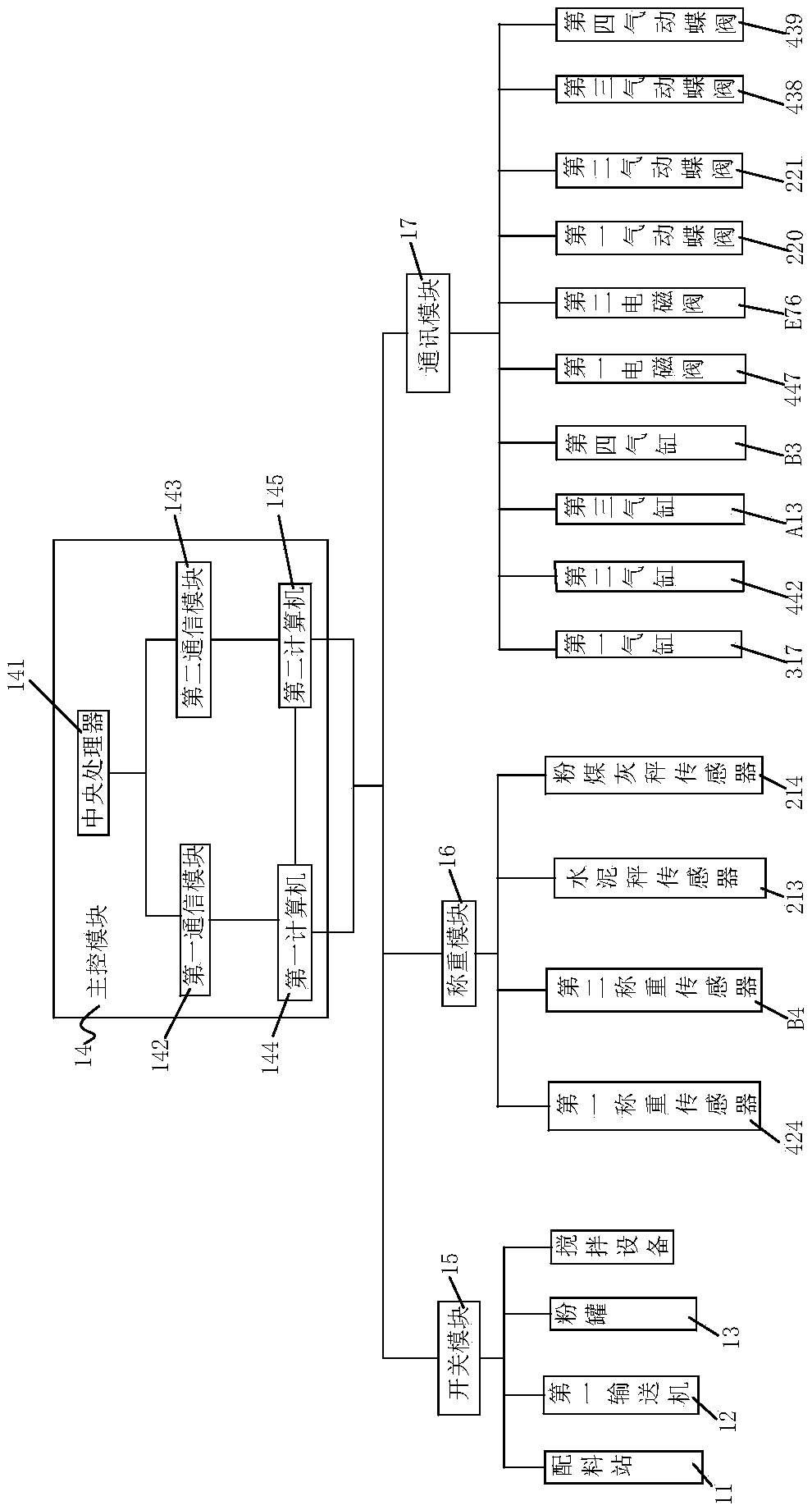

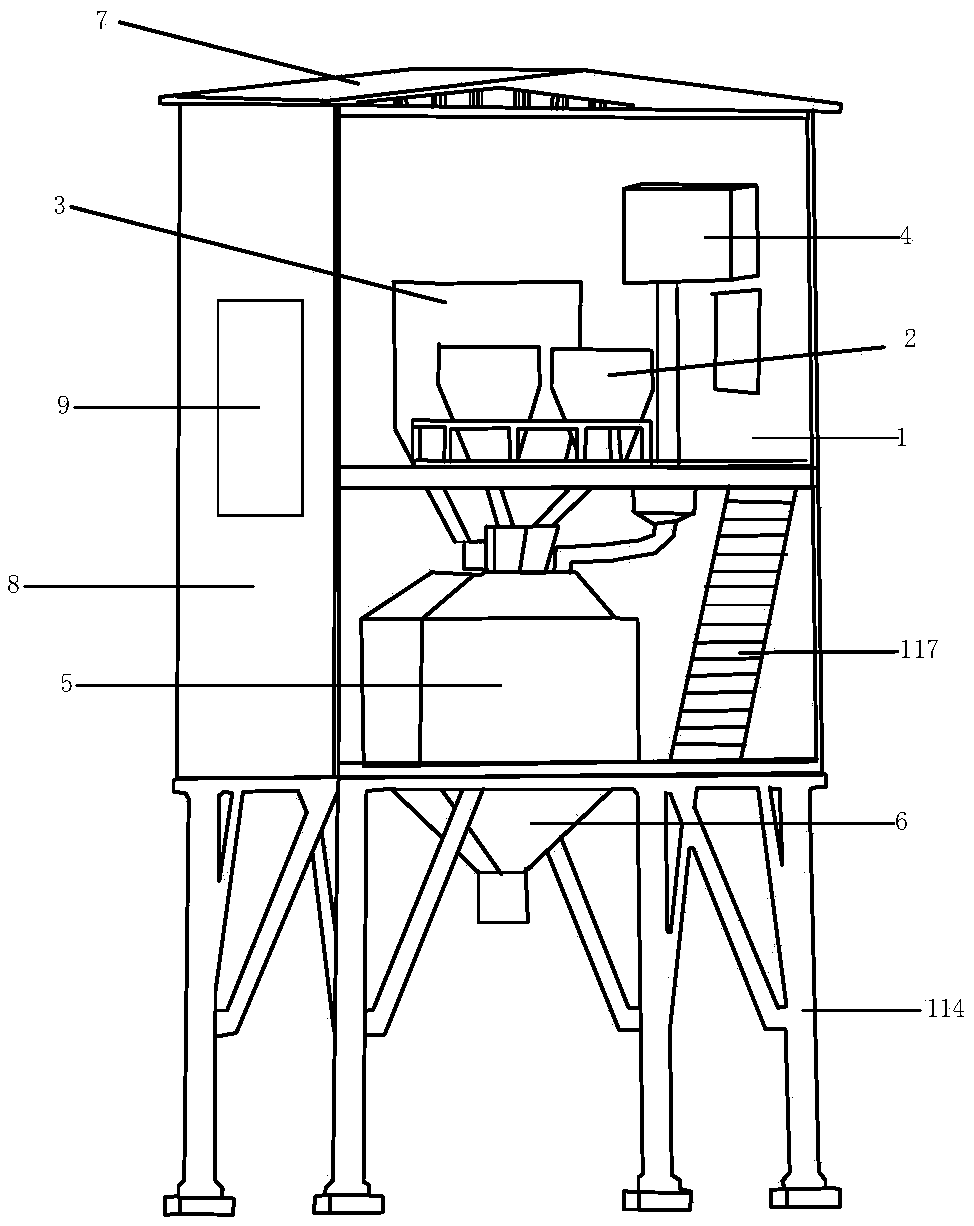

[0057] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. In the figure, the symbol A represents 1111, that is, A1 represents the serial number 11111, B represents 1112, C represents 1113, D represents 12, and E represents 13.

[0058] The present invention as Figure 1-13 As shown, a concrete production equipment includes a batching station 11 for supplying aggregates, a first conveyor 12 for transporting aggregates, a powder tank 13 for storing powder, a mixing device for stirring, and batching The station 11 comprises a storage bin 1111 for storing the aggregate, a second conveyor 1113 for conveying the aggregate onto the first conveyor 12, a material guide for pouring the aggregate onto the first conveyor 12 Device 1114; one end of the first conveyor 12 is arranged under the material guiding device 1114, the other end of the first conveyor 12 is arranged on the mixing equipment, and the powder tank 13 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com