Patents

Literature

52results about How to "Reduce extrusion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

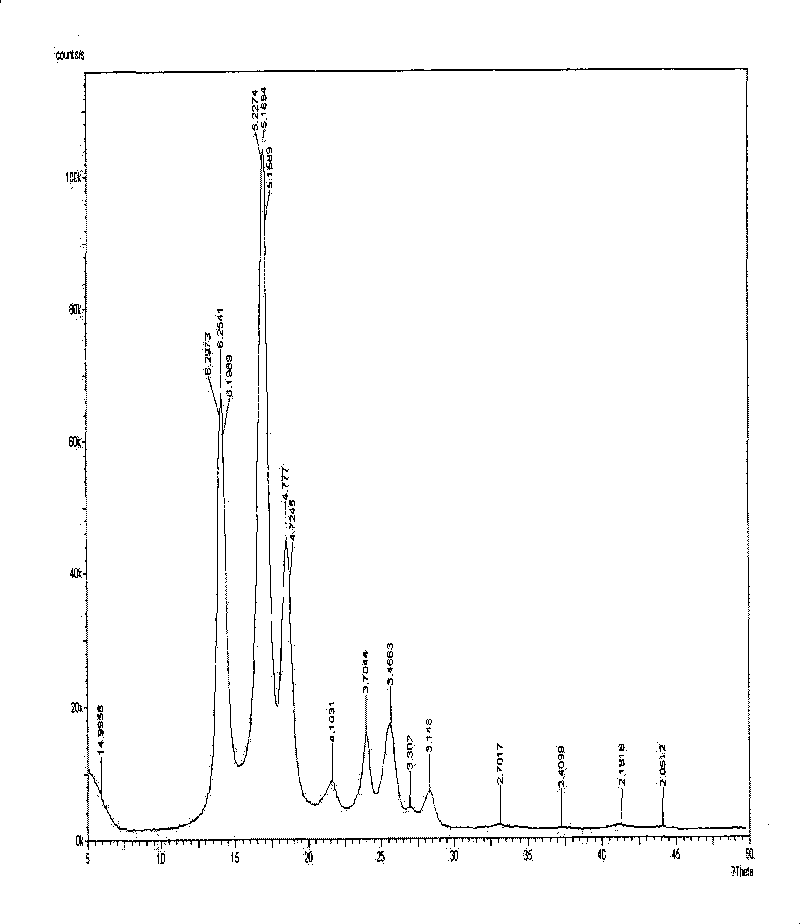

Thin wall cordierite carrier for ceramic honeycomb catalyst and method for preparing the same

InactiveCN1827217AEasy alignmentSmall expansion coefficientCatalyst carriersCeramicwarePorosityCordierite

The invention relates to the improvement on the ceramic beehive catalyst carrier, especially providing a ceramic beehive catalyst carrier with high mechanical strength and lower expansion parameter and preparing method. The invention is characterized in that: said beehive catalyst carrier is the alumina micro powder in 12-15%WT whose average particle diameter is less than 2 micron; the sheet kaolin and / or clay micro powder in 43-47% whose average particle diameter is less than 2 micron, the sheet steatite micro powder in 33-37% whose average particle diameter is 5-15 micron, and the fuse quartz in 6-12% whose average particle diameter is less than 2 micron to be mixed, molded and baked to attain the cordierite whose total amount is 92-96%, wherein, the Al203, MgO and SiO2 are each in 36-37%, 13.0-14.0% and 50-52%. The invention adds surface active agent in the mixture when in preparation. The prepared beehive cordierite total amount with 600 hole / square inch can reach 92-96%, the expansion parameter can reach 0.8X10-6 / Deg. C (800Deg. C to room temperature), and the factor of porosity can reach 39-40%. The invention can reduce the ignition temperature 25-40Deg. C, and reduce the tail gas discharge of nitrogen oxygen compound and carbon monoxide of vehicle 5-10% to meet the demand of Europe III standard.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY +1

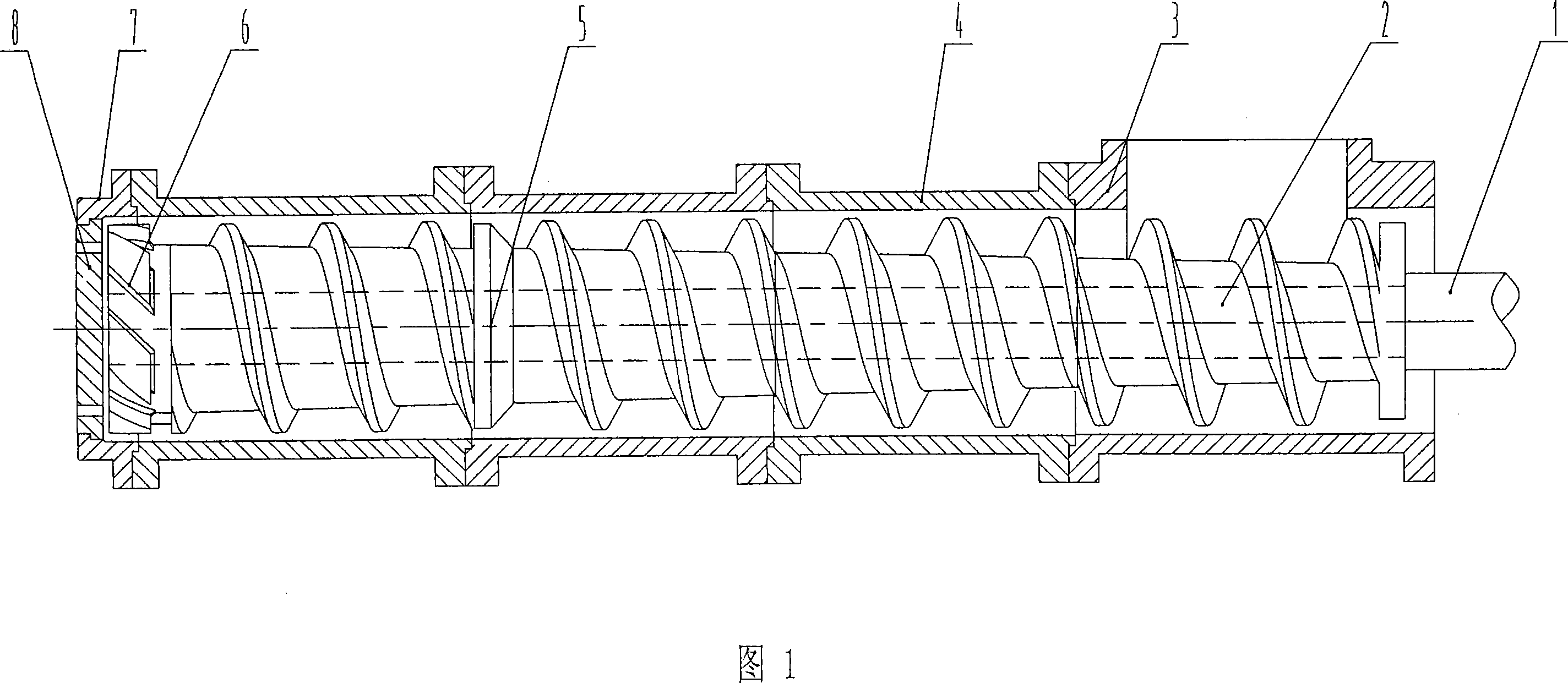

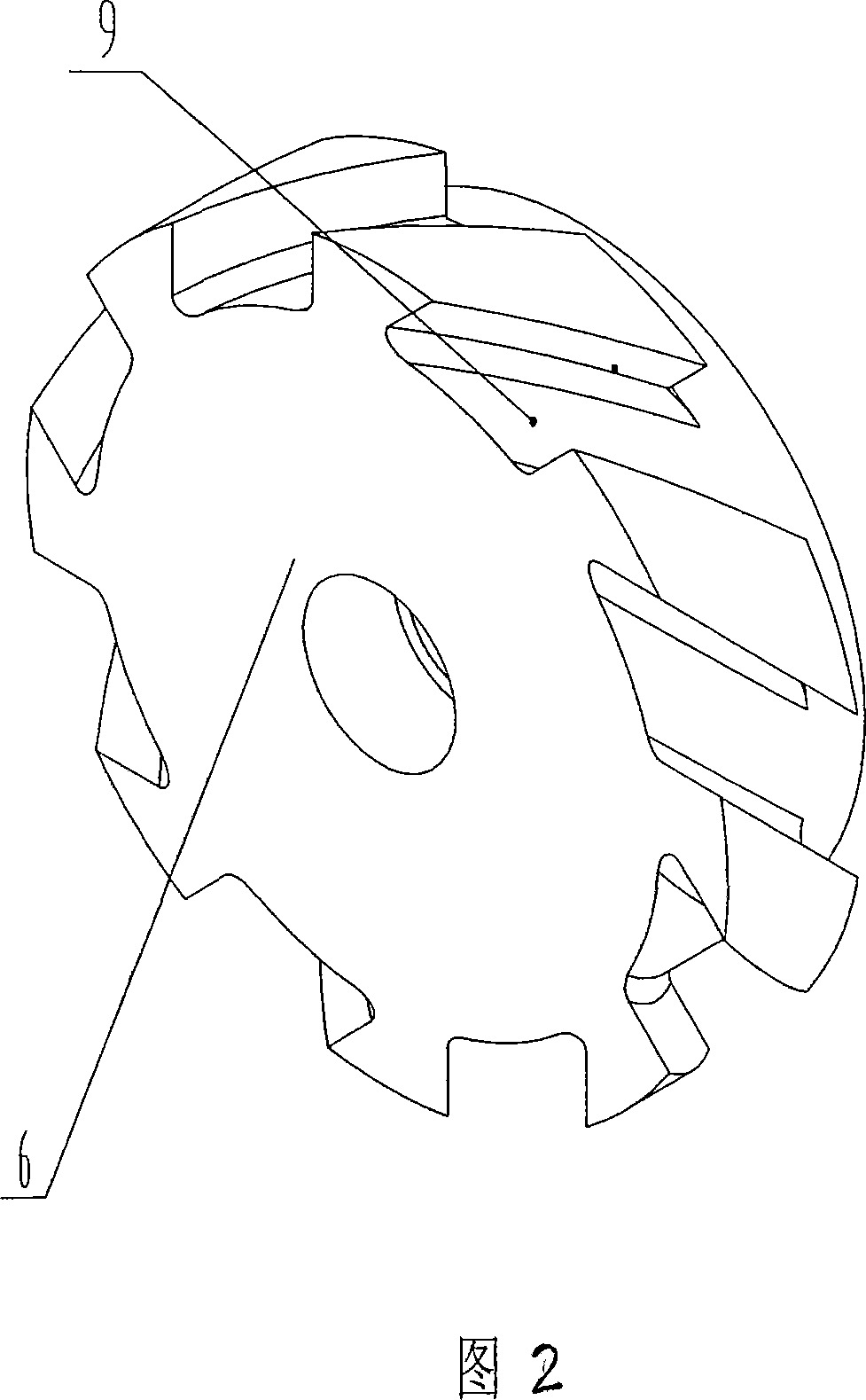

Puffing machine for high starch materials puffing

InactiveCN101057702AReduce deliveryRelieve pressureFeeding-stuffAnimal feeding stuffPulp and paper industryEnergy consumption

The invention discloses a puffing machine which is used for starch-rich material puffing, belonging to puffing-machine field. It mainly comprises: main axle, pressure ring, segmented bolt, feeding cavity, segmented compression cavity, discharging device and squeezing air spout. A cylindrical diverting body is fixed between segmented bolt and squeezing sir sprout, the outer surface of diverting body is equipped with a plurality of spiral directional slots, the two ends of directional slot extend to the two ends of diverting body, the rotary direction of directional slot is in accordance with that of bolt. The material can be diverted evenly and fed into squeezing air sprout and discharged from squeezing air sprout continuously because of the homogenous distribution of directional slots on the circumference. The continuous material discharging guarantees device stability, and because the diverting body provides a propelling force, the material with large adhesiveness can also be conveyed easily, and the machinery energy consumption is reduced, productivity is increased.

Owner:JIANGSU MUYANG GRP CO LTD

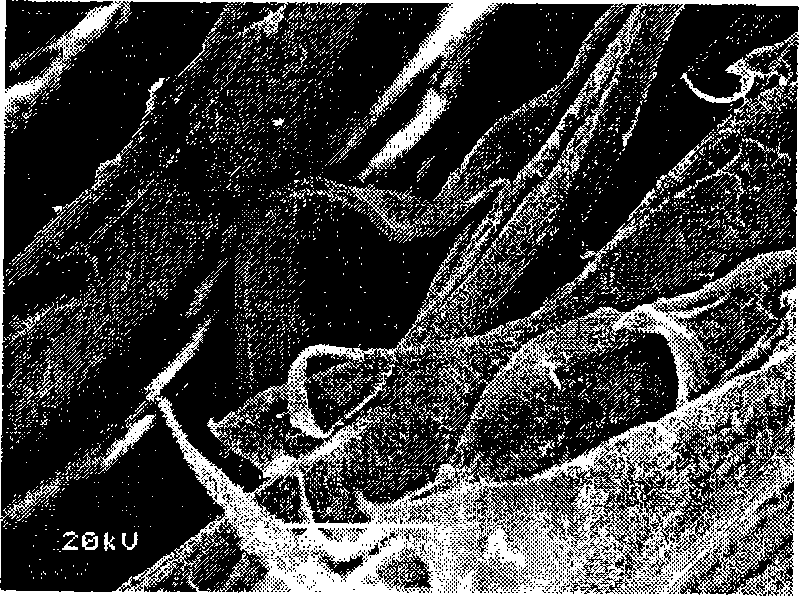

Preparation method of anesthesia stem and plastic composite material

ActiveCN101081934AReduce extrusion resistanceImprove mobilityPlastic compoundingWood-plastic composite

The present invention discloses preparation process of composite material of hemp stalk and plastic. The composite material is prepared through mixing hemp stalk powder and mineral powder to obtain composite hemp stalk powder, extruding and pelletizing to obtain composite hemp stalk pellet, mixing with plastic, and pelletizing or extruding into product. The composite material is environment friendly, reusable and low in cost.

Owner:凌彩百川(新兴)科技有限公司

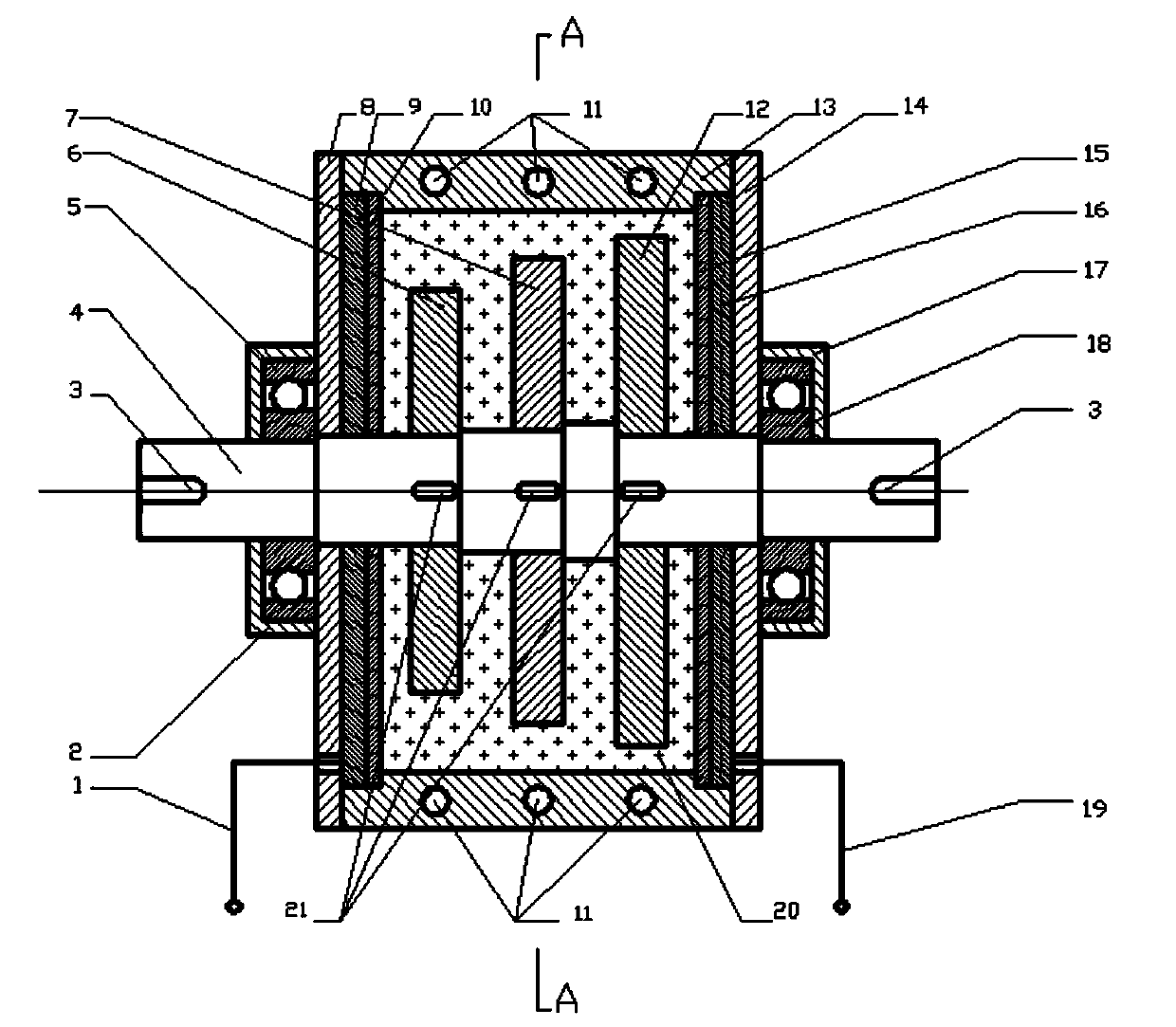

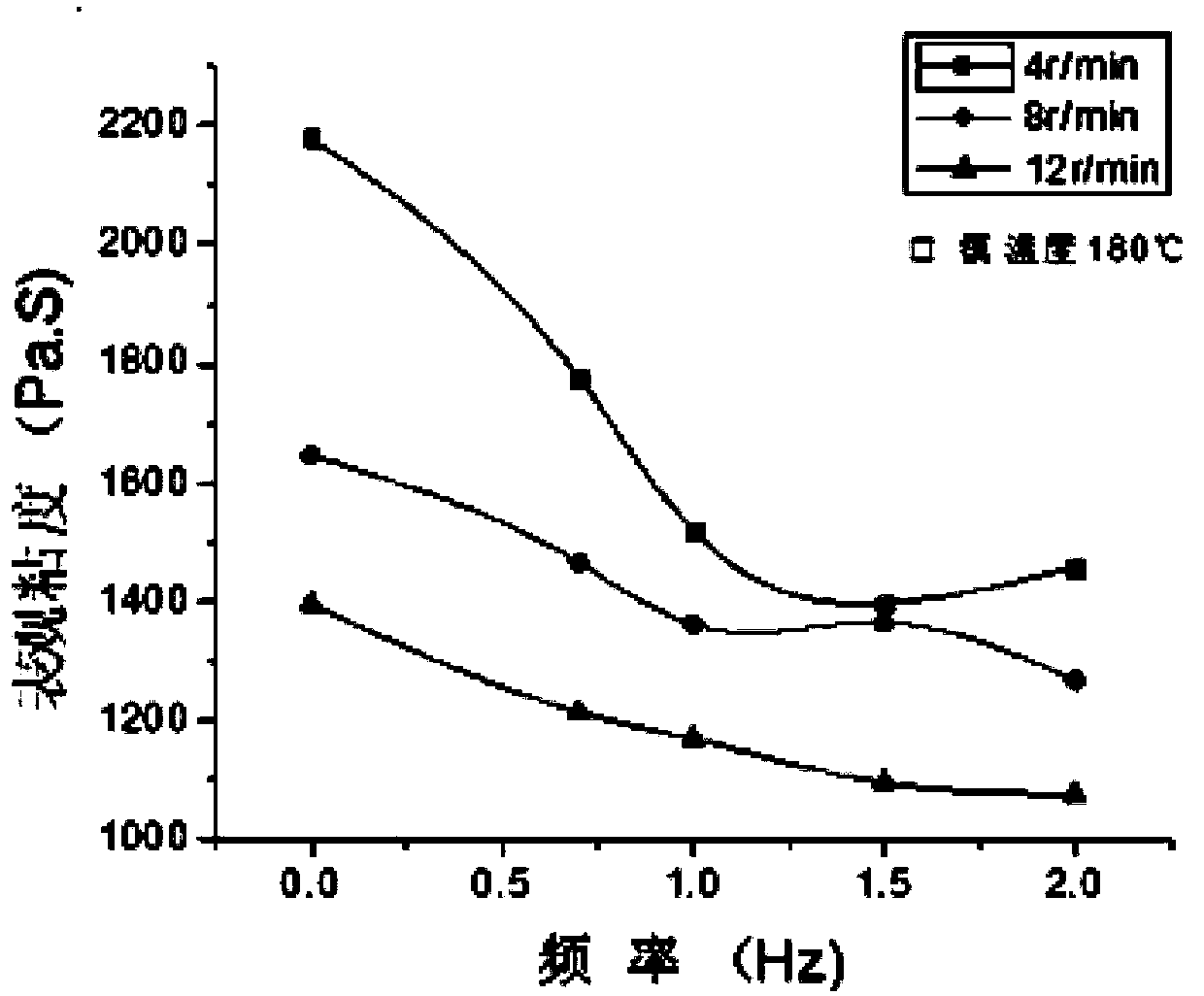

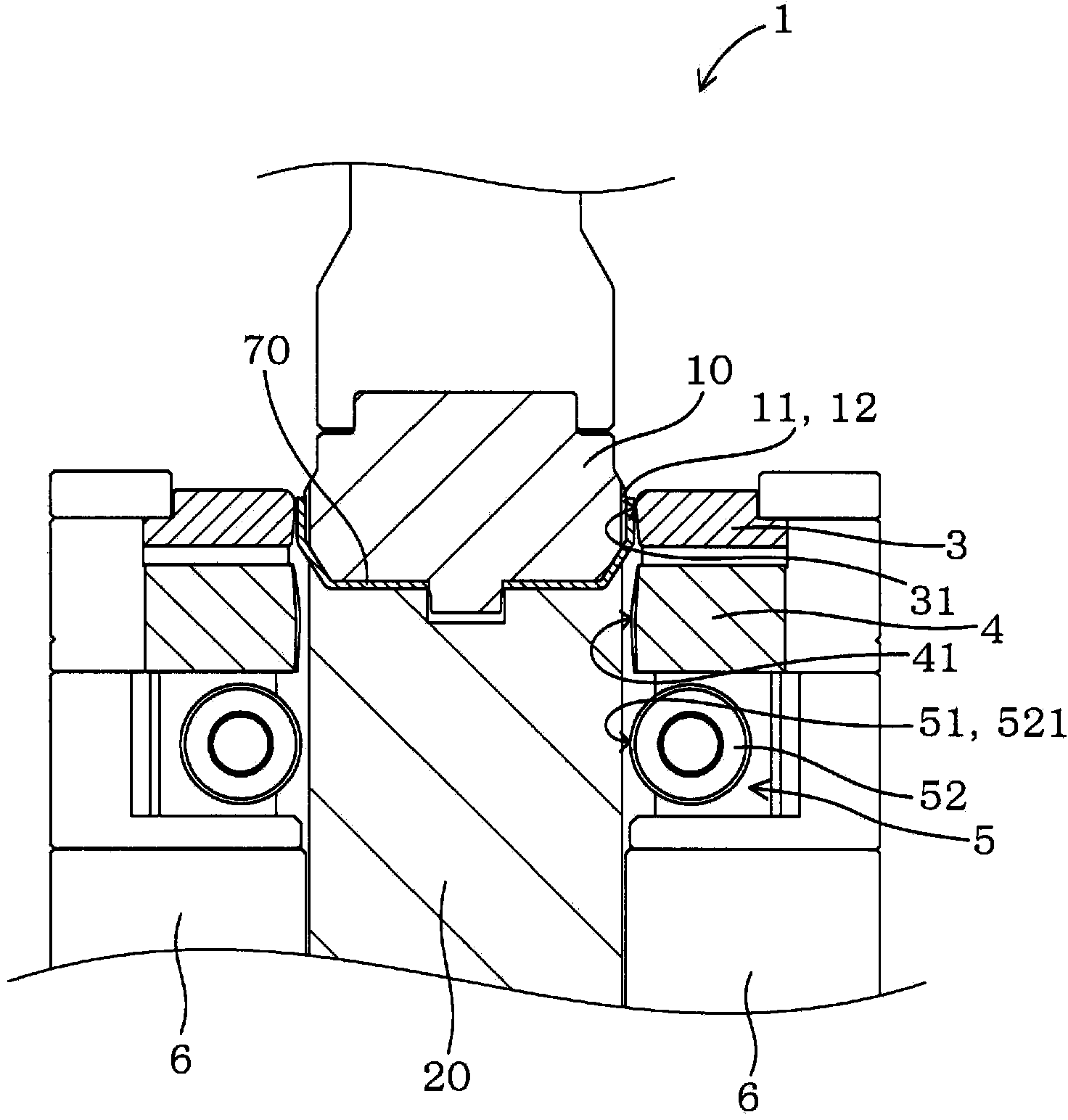

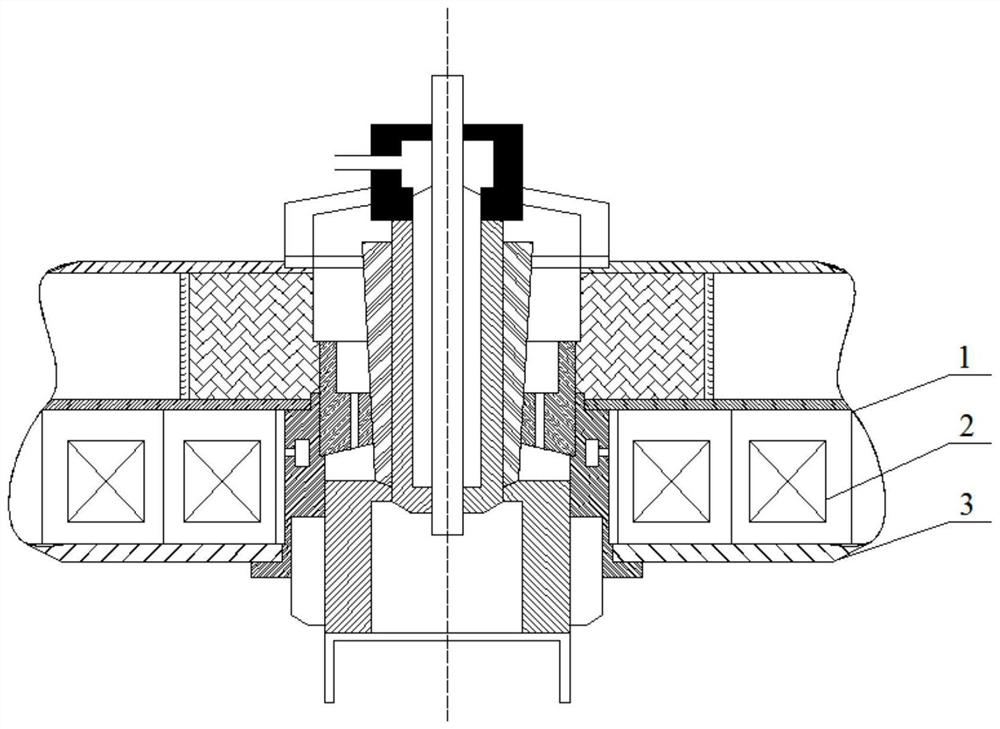

Seven-stage adjustable rotary type electrorheological fluid brake

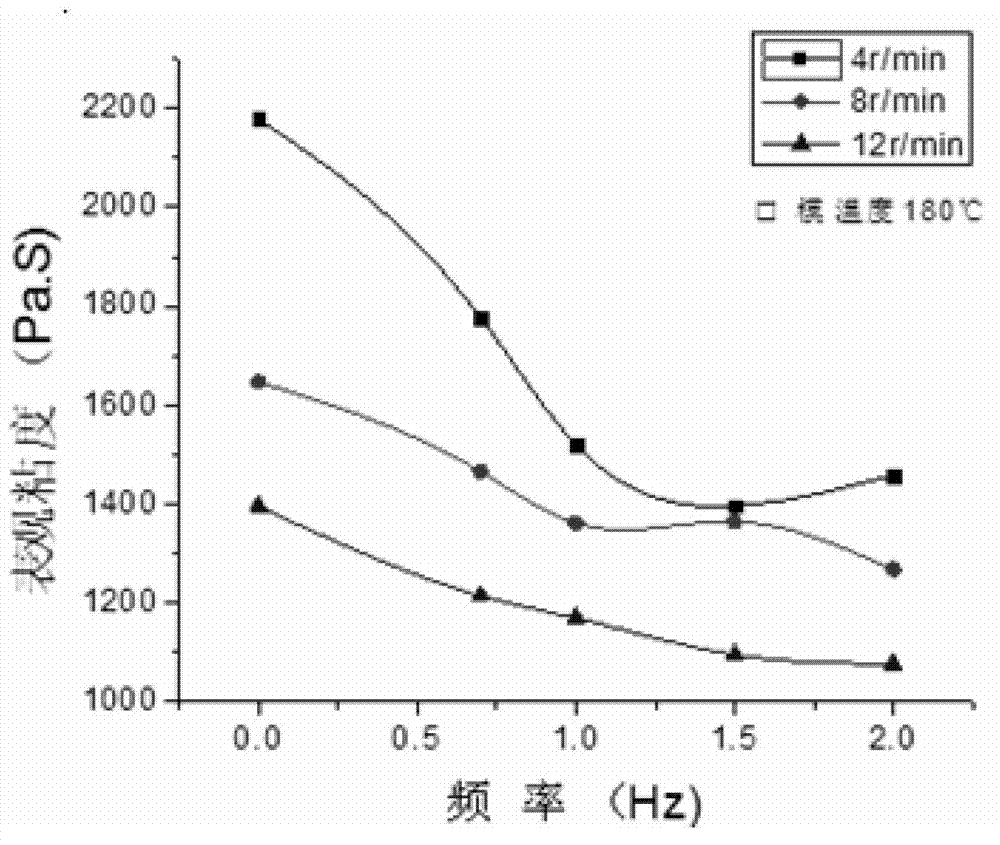

InactiveCN103697090AIncrease structural flexibilityLarge braking forceLiquid resistance brakesBrake actuating mechanismsThrottle controlApparent viscosity

The invention provides a seven-stage adjustable rotary type electrorheological fluid brake. The seven-stage adjustable rotary type electrorheological fluid brake mainly comprises a positive pole conducting wire, a negative pole conducting wire, a bearing cap, a bearing, an end closure, conductive rubber, a half round key, a rotating shaft, an insulated shell, a positive pole, a negative pole, a backflow control channel, a small turntable, a middle turntable, a large turntable, electrorheological fluid and a flat key, wherein the installation type of the small turntable, the middle turntable and the large turntable is decided by suffered braking force, when the braking force is large, the stress is not clear and the rotating speed is high, the dual-turntable and three-turntable type is adopted; when the braking force is small, the single-turntable type is adopted; the backflow control channel is used for replacing a throttling control valve, an external electric field is not applied, and the electrorheological fluid is stressed, flows between the upper part and the lower part of the insulated shell through the backflow control channel and is a hydraulic brake; when the external electric field is applied and the high shear rate is adopted, the apparent viscosity of the electrorheological fluid of the backflow control channel changes, so that the sectional area of the electrorheological fluid becomes small till being completely closed; and the electrorheological fluid realizes the effective brake on an engineering system by providing shear force and extrusion force.

Owner:QINGDAO AGRI UNIV

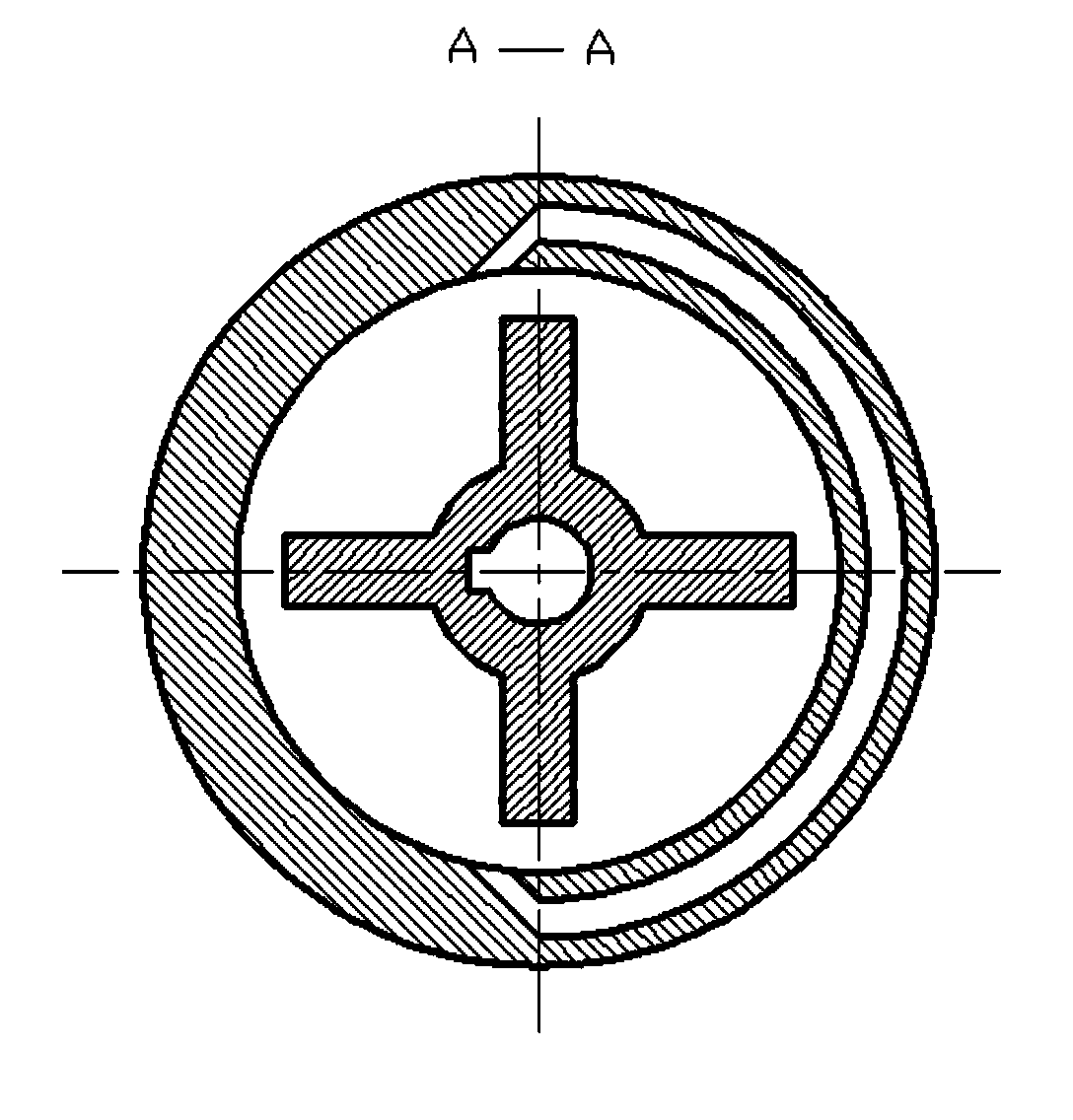

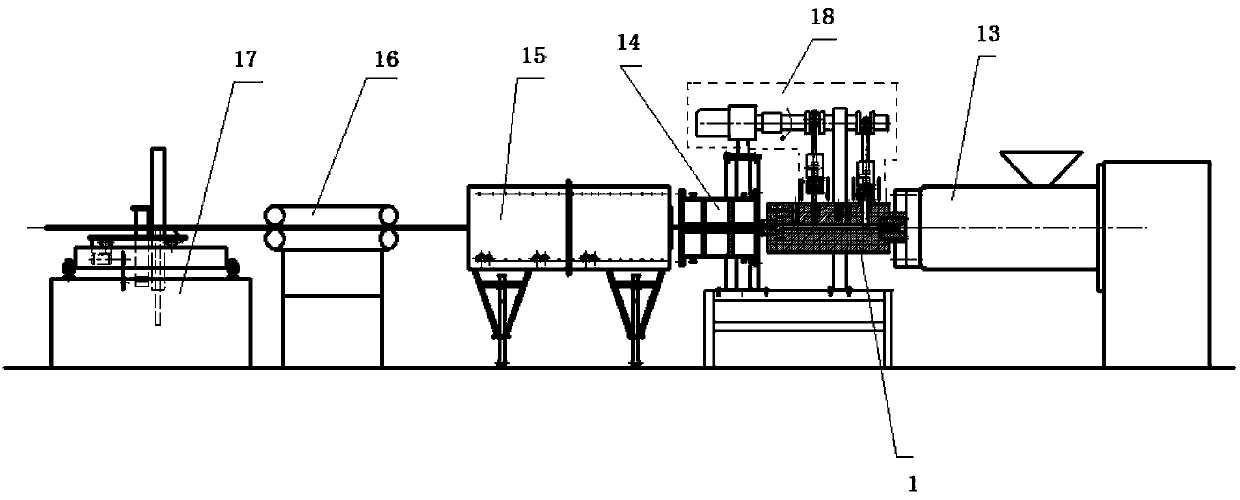

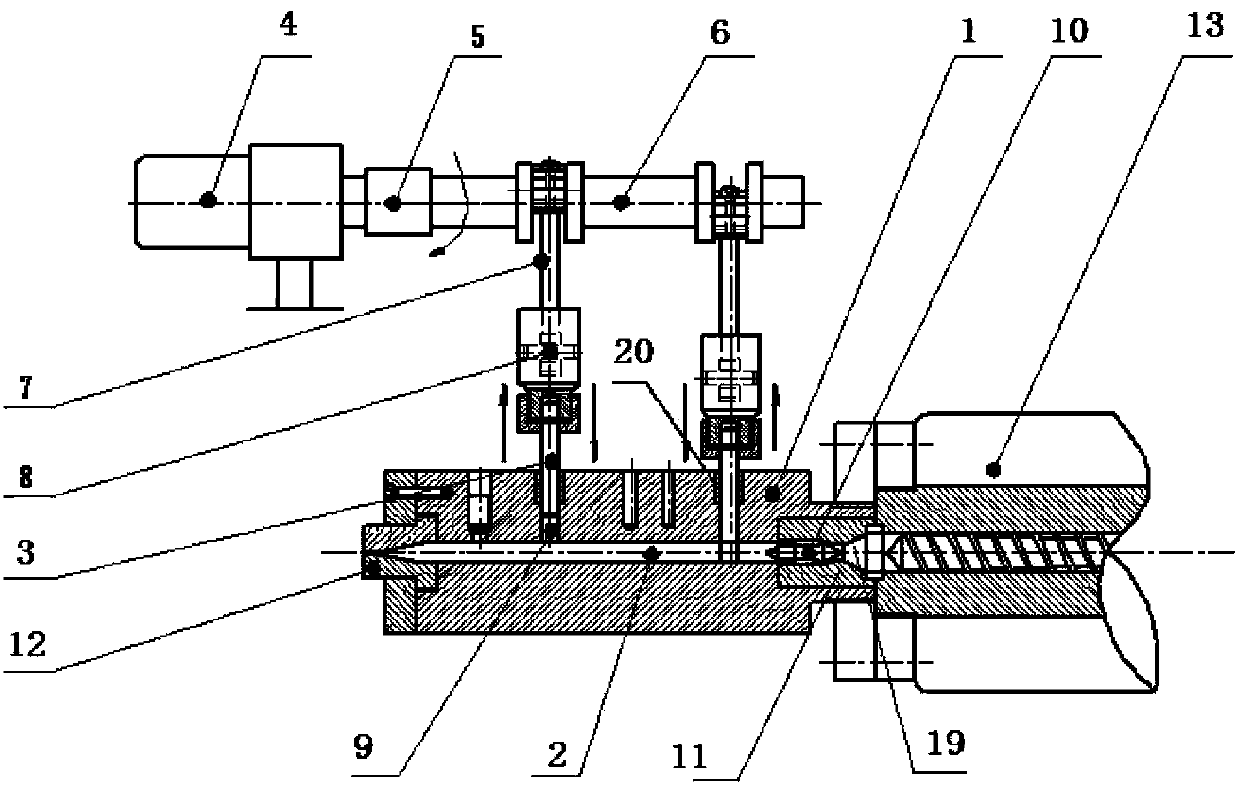

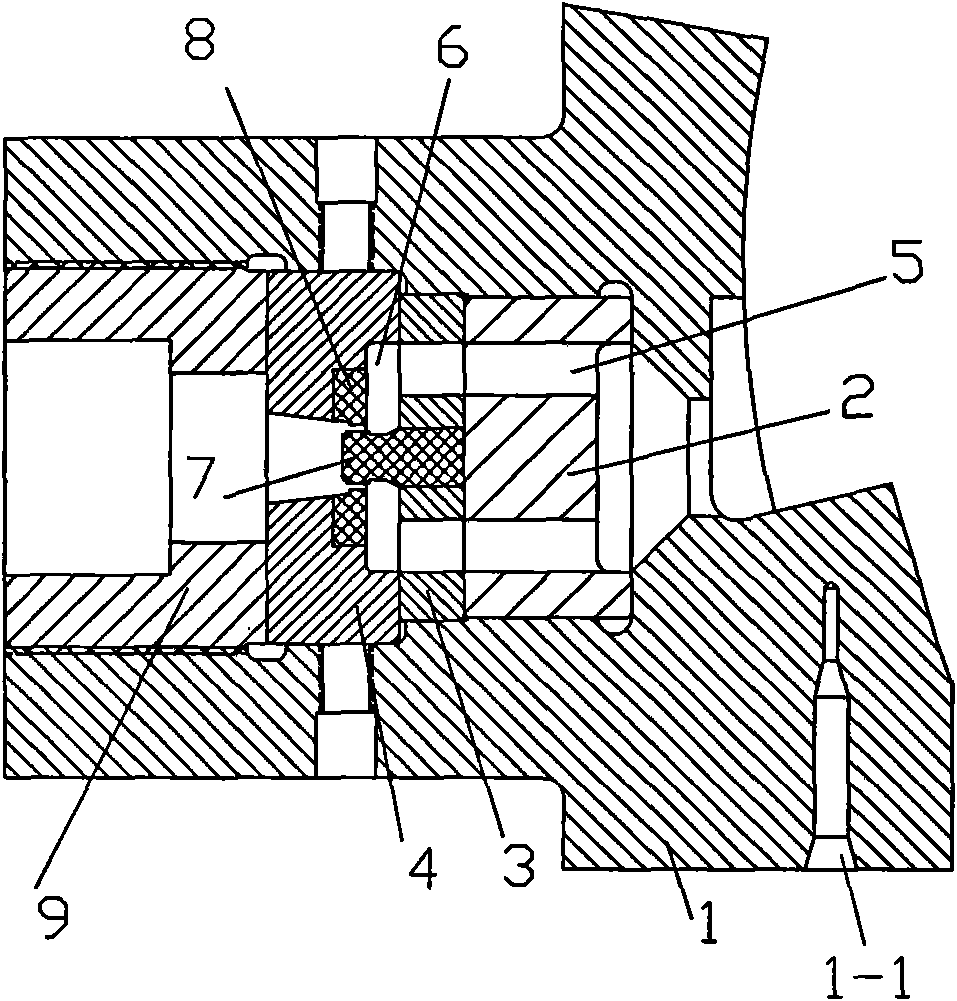

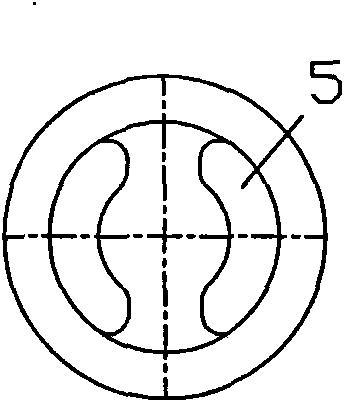

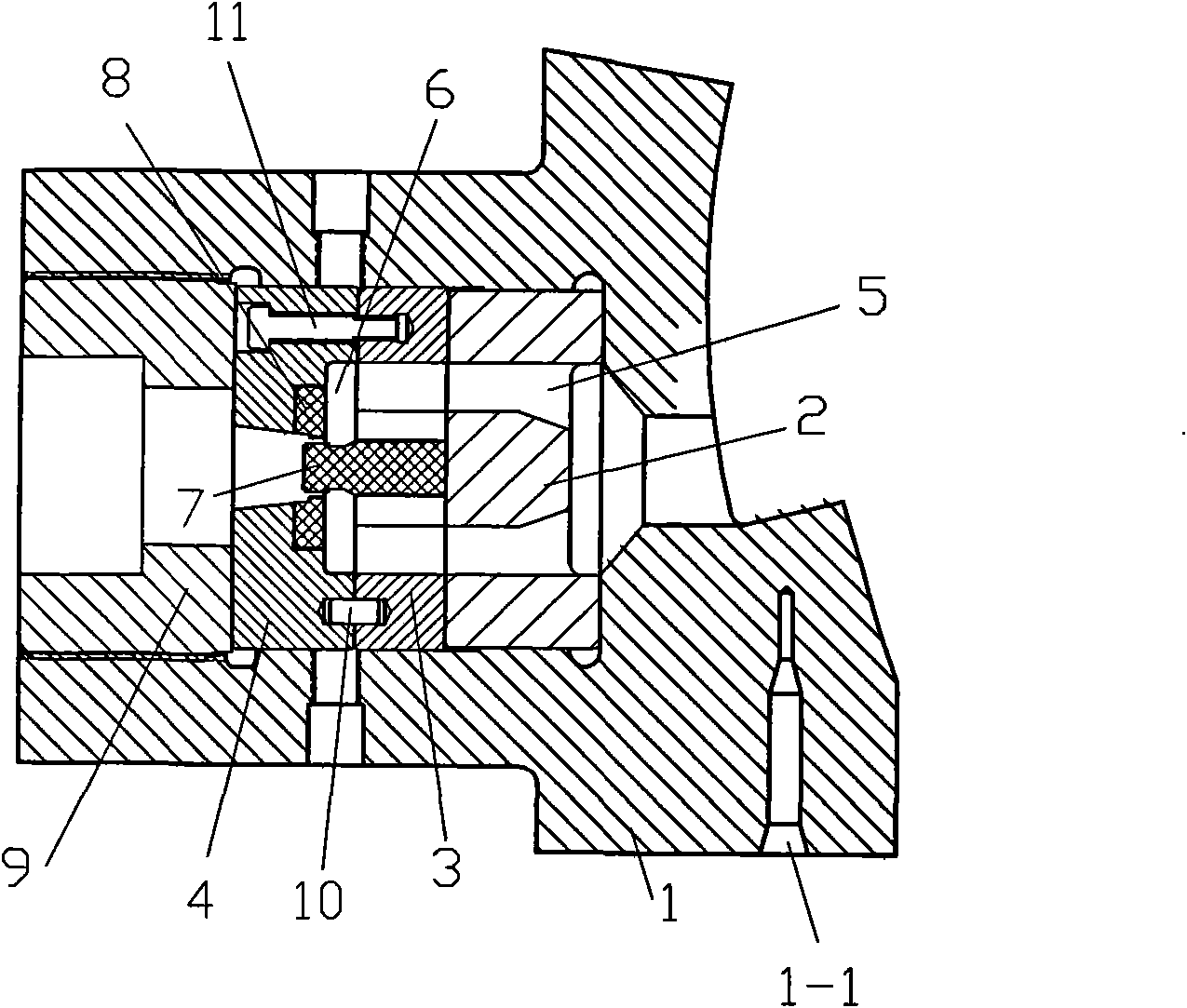

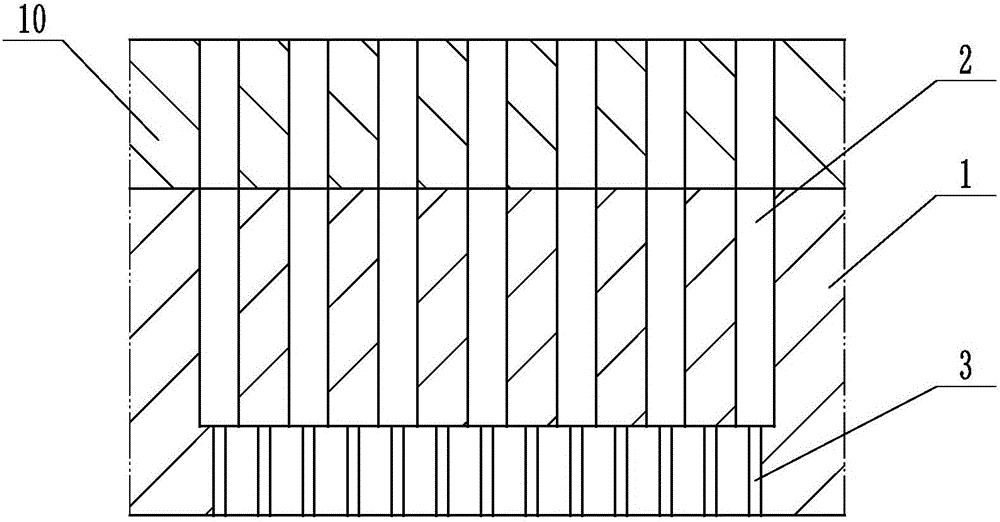

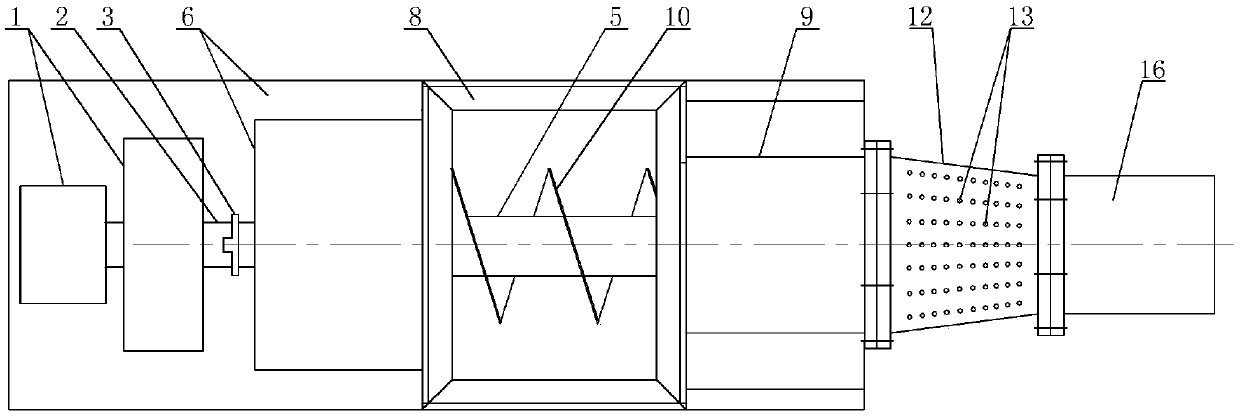

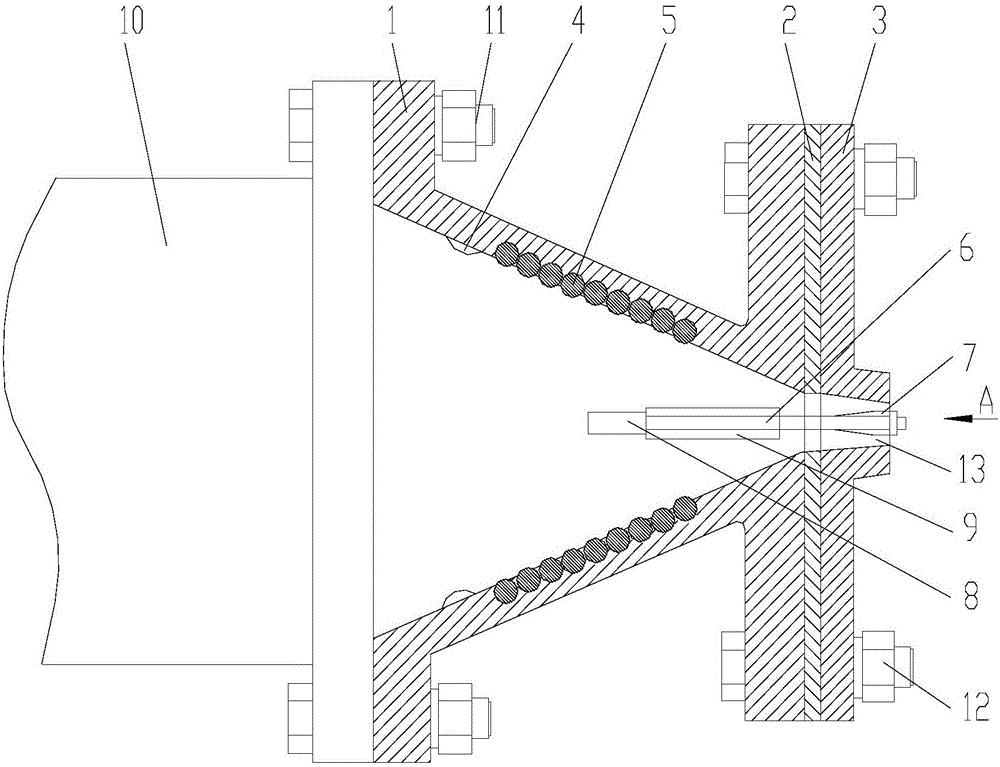

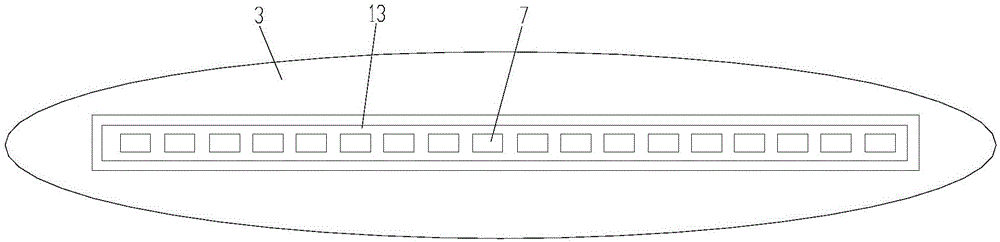

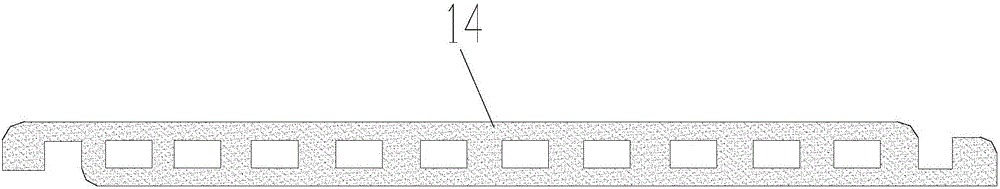

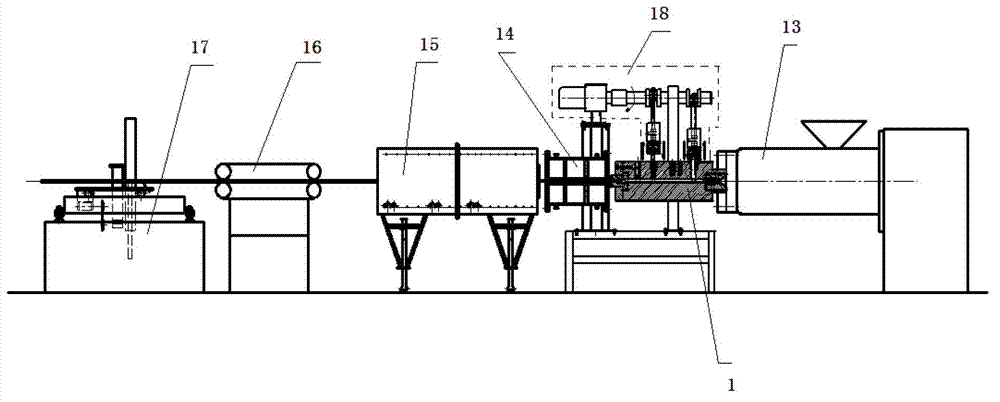

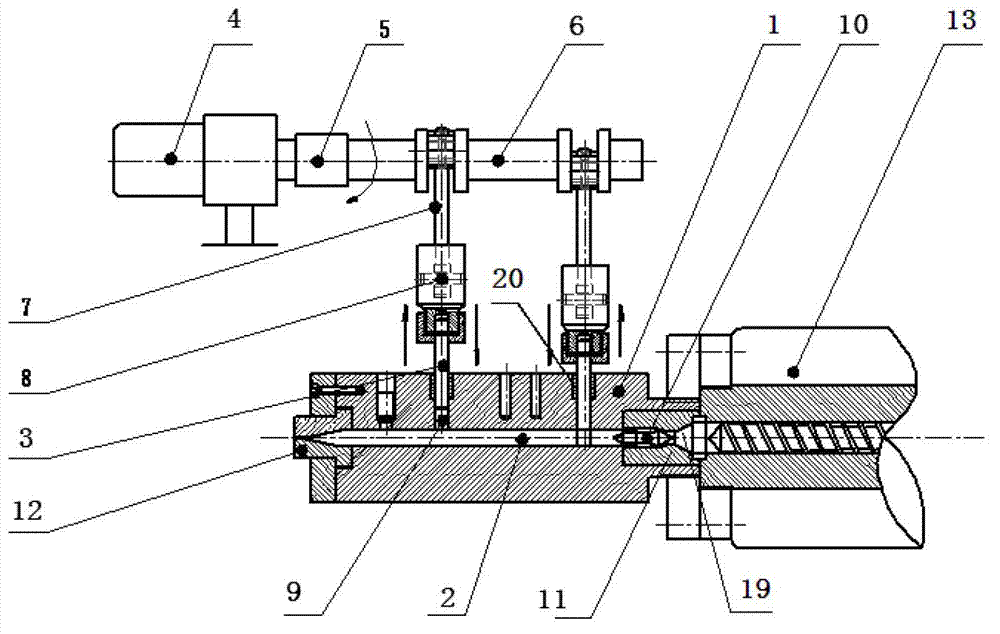

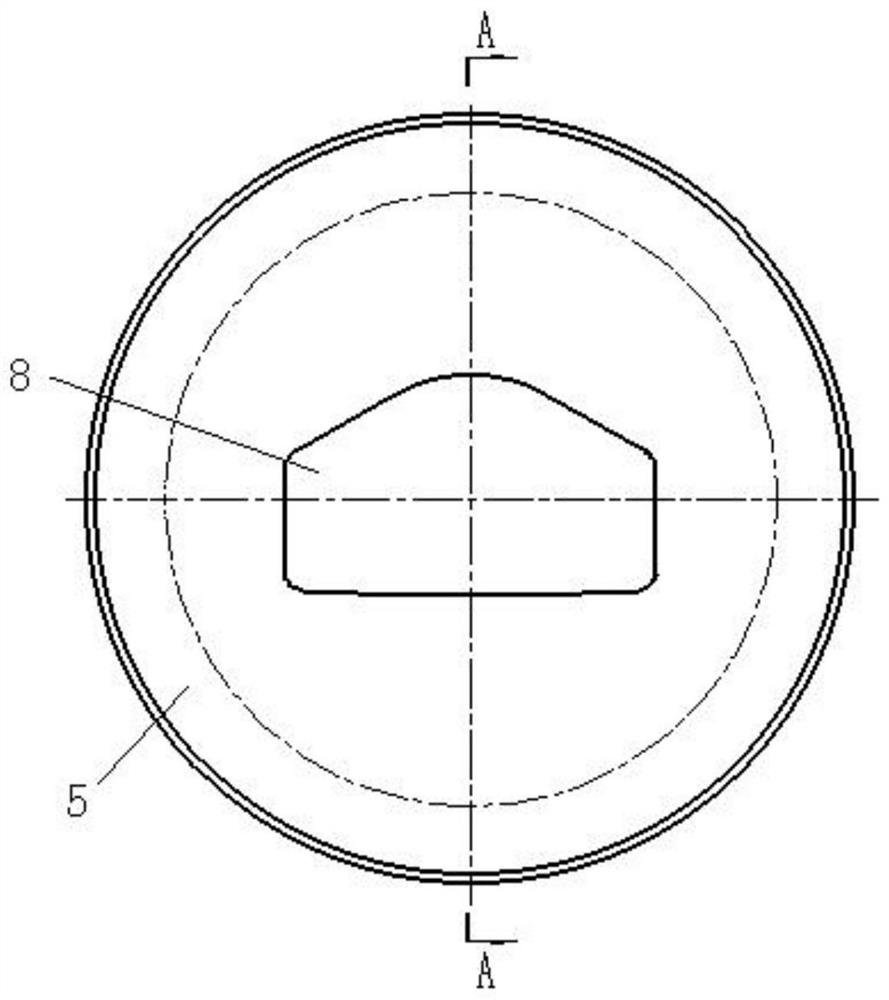

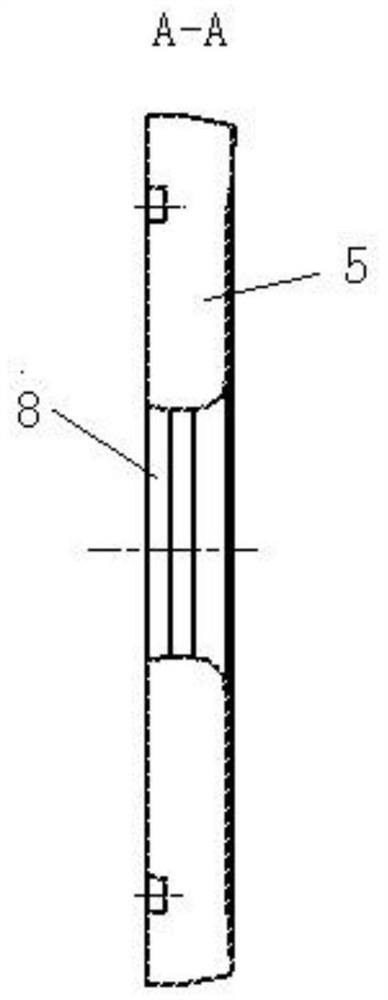

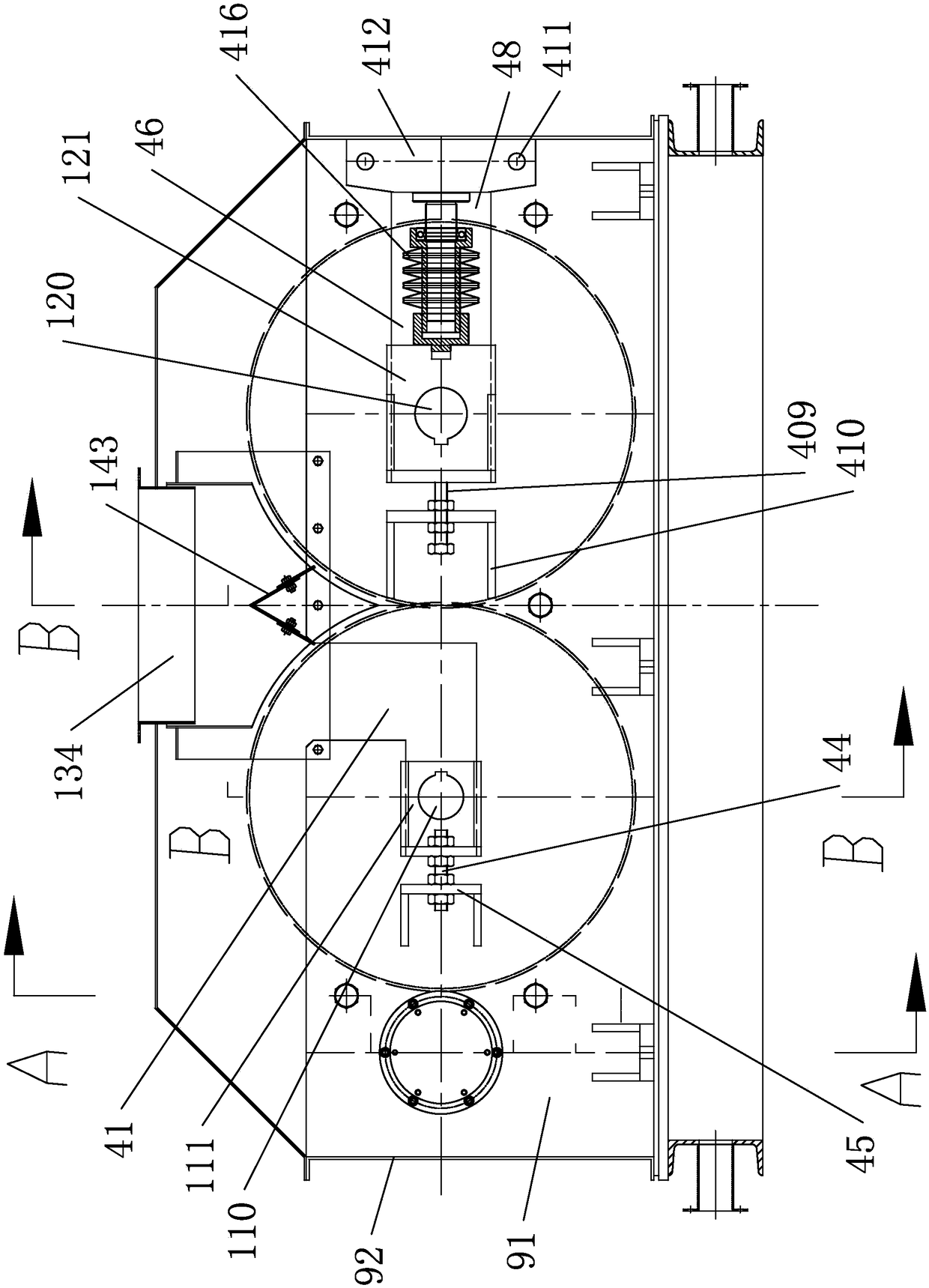

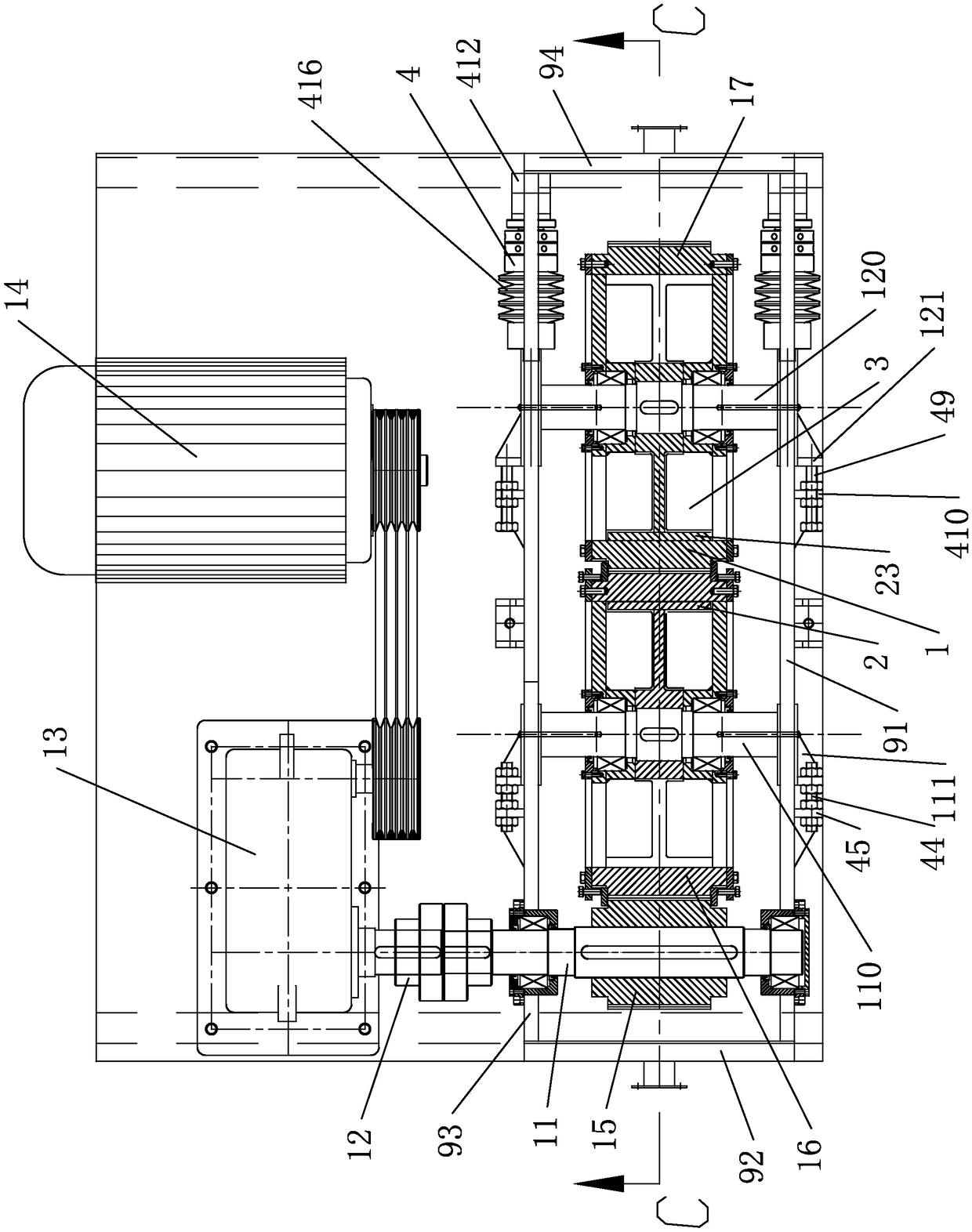

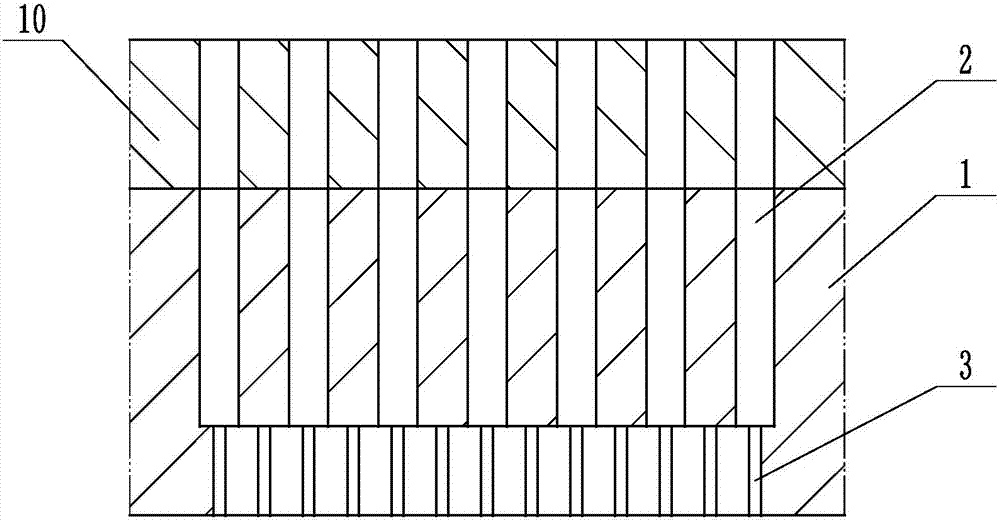

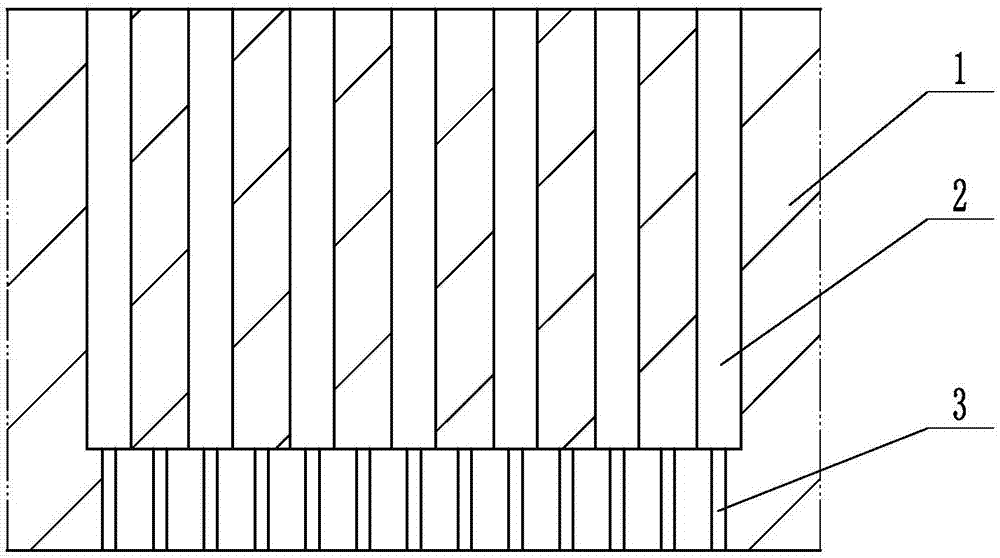

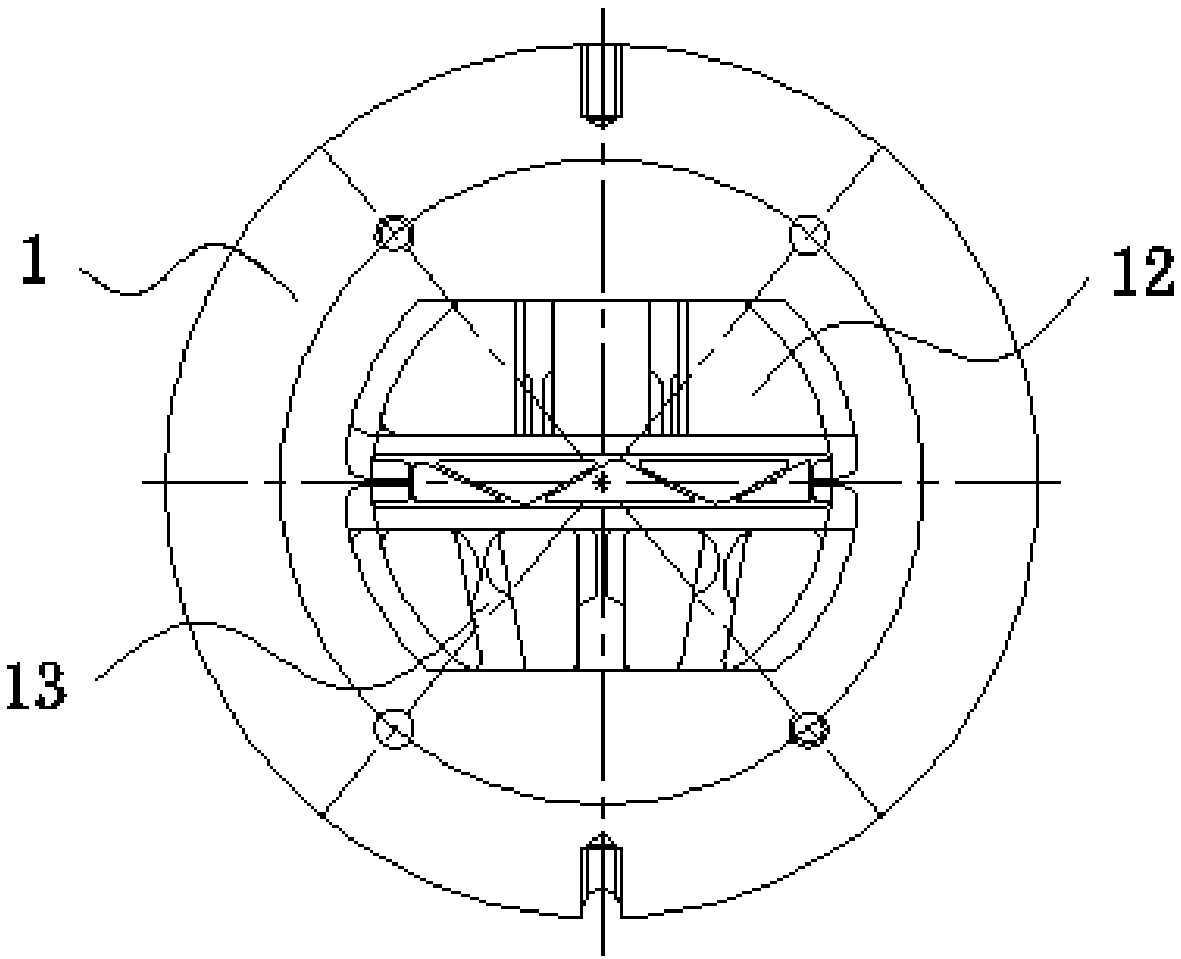

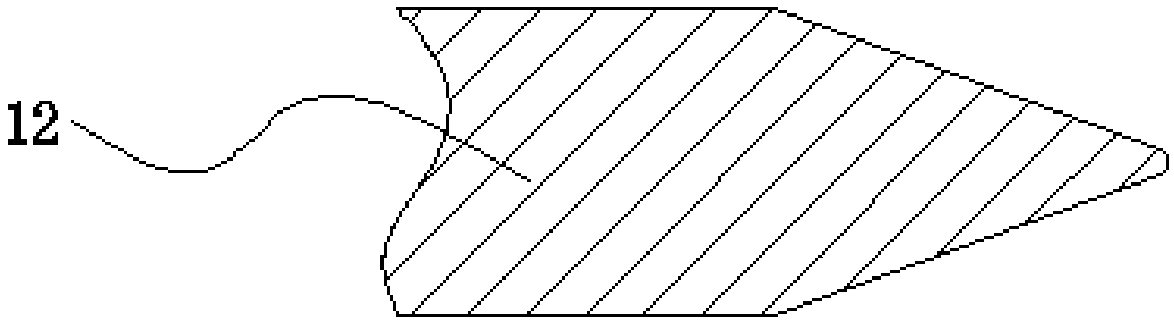

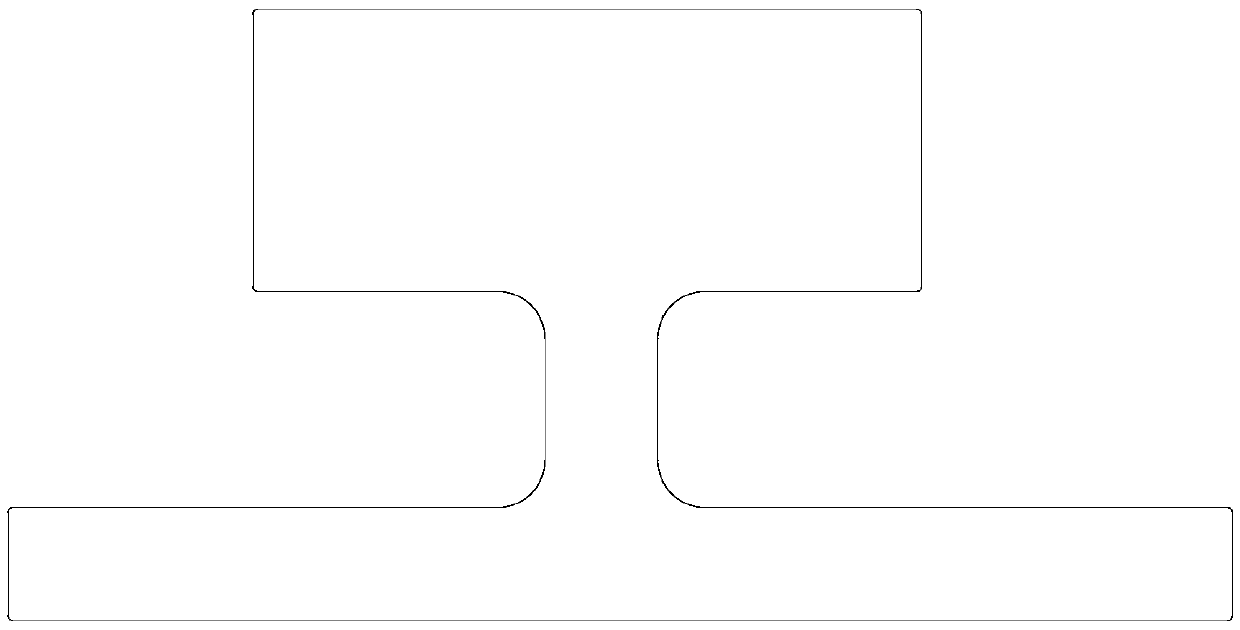

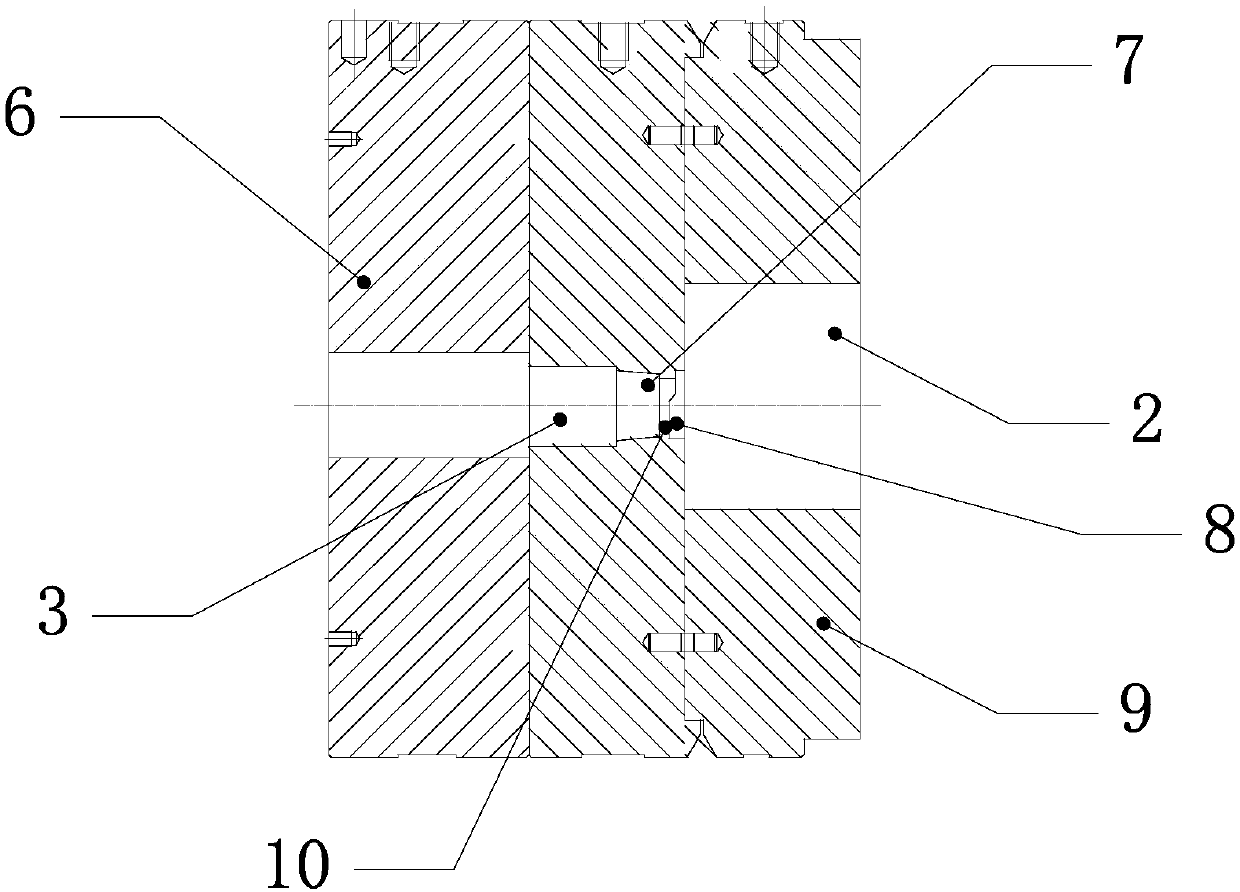

Polymer melt shear vibration extrusion molding device

The invention provides a polymer melt shear vibration extrusion molding device which comprises an extruding machine 13, an extrusion head 1 connected with the extruding machine through a flange plate, a mouth mould 12, a stock mould 14, a cooling water tank 15, a traction device 16 and a cutting device 17, and is characterized by further comprising a crank connecting rod shear vibration system 18 and a melt runner vibration chamber 2, wherein the crank connecting rod shear vibration system 18 is arranged above the extrusion head 1; the melt runner vibration chamber 2 is arranged inside the extrusion head 1; the crank connecting rod shear vibration system is composed of a crank connecting rod mechanism and a reciprocating vibration rod 3; the reciprocating vibration rod 3 is positioned in a through hole 9 formed in the extrusion head 1; the through hole 9 is communicated with the melt runner vibration chamber 2. The device provided by the invention not only can simultaneously promote polymer molecule chain orientation, shish-kebab structure generation and polymer crystalline grain refinement, and improve mechanical property of products, but also can reduce extrusion resistance and improve production efficiency.

Owner:SICHUAN UNIV

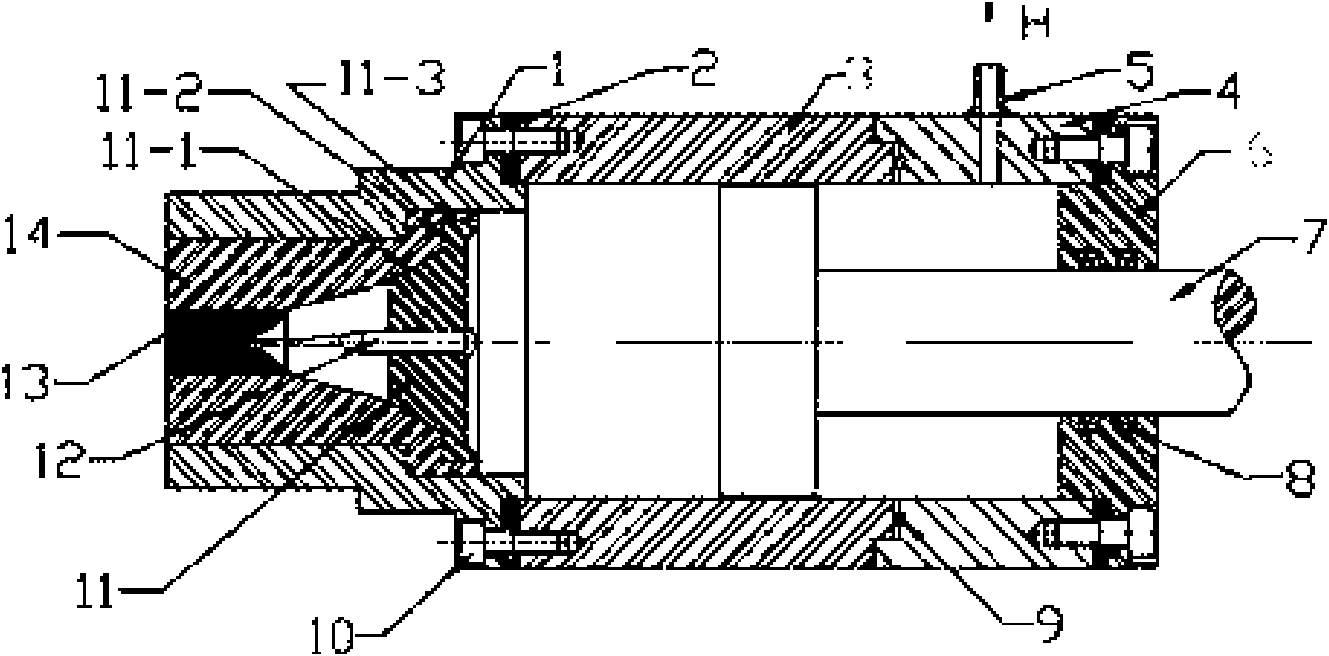

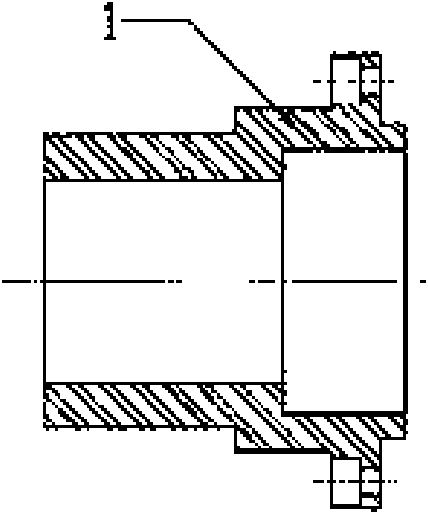

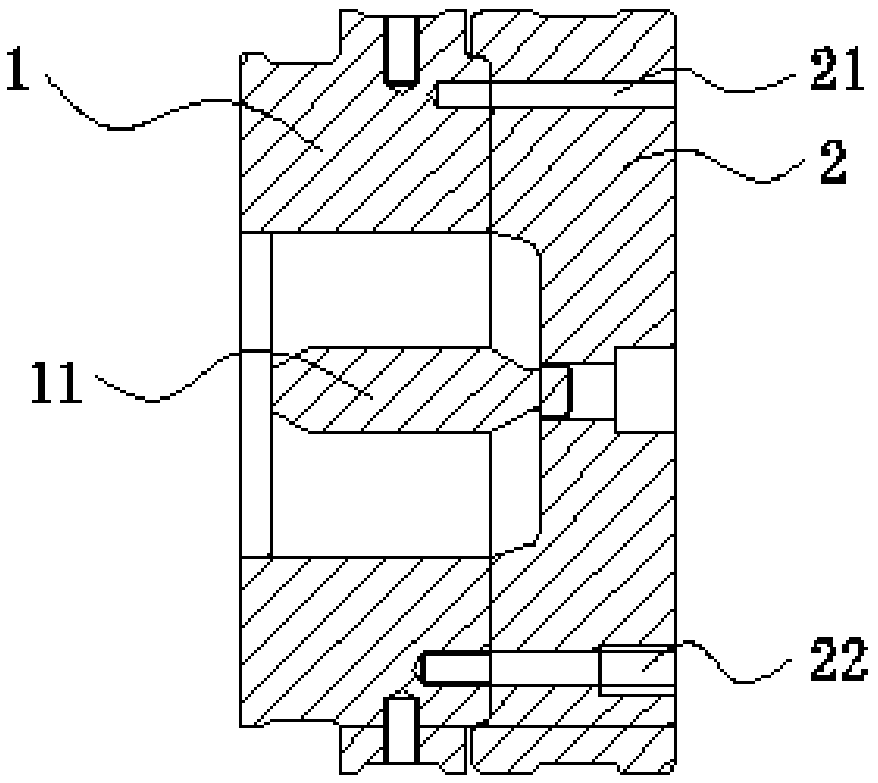

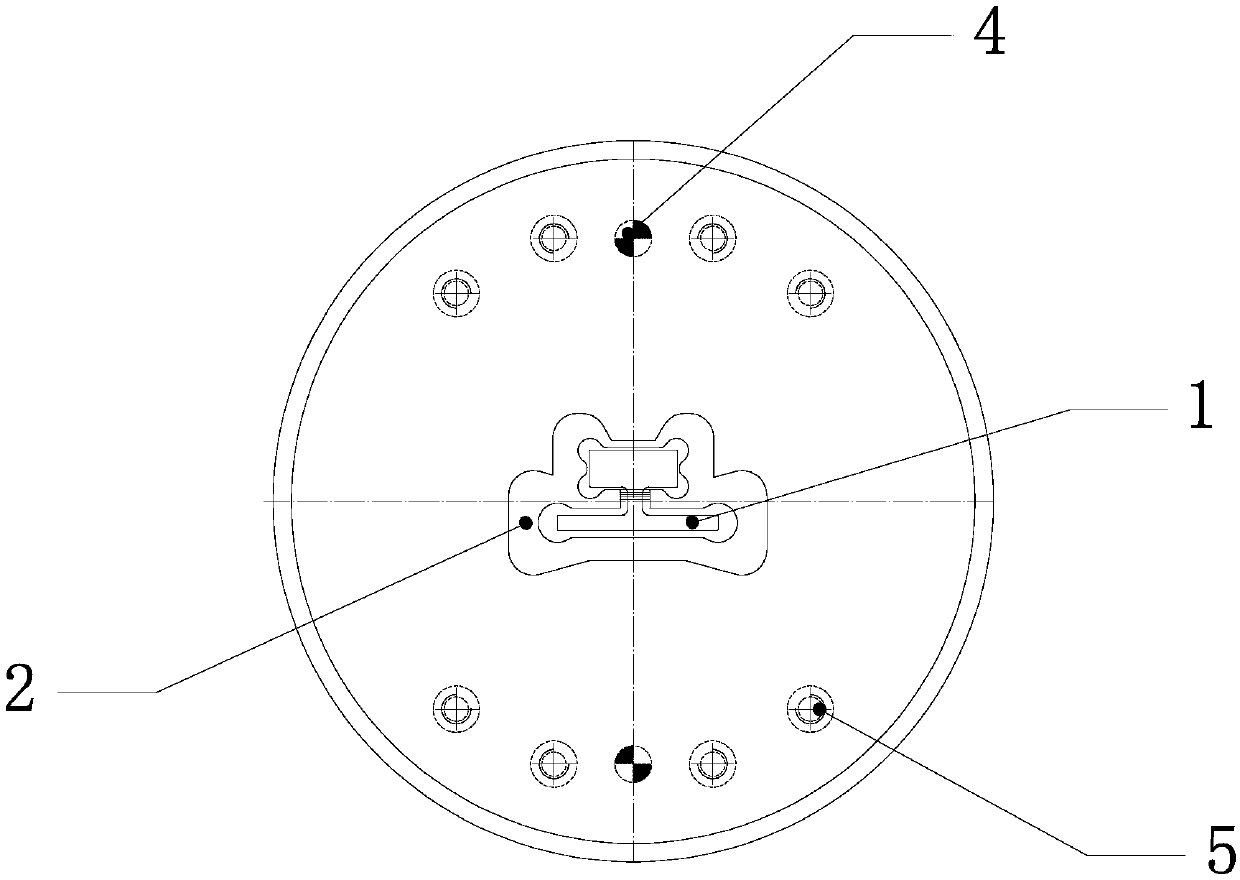

Extruding device of porous hard alloy profile

InactiveCN101664769AReduce extrusion resistanceReduce loadExtrusion diesExtrusion control devicesCemented carbideVacuum state

The invention discloses an extruding device of a porous hard alloy profile. A mold system thereof consists of a core rod bracket (11), an extrusion core rod (12), a mold (13) and a mold sleeve (14), which are movably assembled in a die set (1); a pressing cylinder system comprises a front pressing cylinder (3), a rear pressing cylinder (4), an extrusion pushing rod (7) and a rear end cover (6), wherein the rear pressing cylinder (4) is provided with an air vent; an air exhaust opening (5) above the air vent is coupled with a vacuumizing system; the extrusion pushing rod (7) passes through therear end cover to be connected with a hydraulic system; and the die set (1), the front pressing cylinder (3), the rear pressing cylinder (4) and the rear end cover (6) realize sealing connection by fastening screws and a pull rod mechanism so as to form an extrusion device body. The length of the hard alloy profile and the hole diameter of the inner hole, extruded by the device, are not limited, the extrusion process is ensured under vacuum state to ensure good internal quality of an extruding part, and the difficulties that the existing porous high-performance hard alloy has short profile length, large size of the hole diameter, and air holes in the inner part when being extruded and molded are solved.

Owner:FUJIAN JINXIN TUNGSTEN

Preparation method of plastic wood composite material

The present invention relates to a plastics wood composite material and its preparation method. Said method includes the following steps: firstly, pulverizing laminate structure mineral, adding coupling agent while stirring to obtain coupled laminate structure mineral powder; adding coupling agent while stirring wood powder to obtain coupled wood powder; mixing coupled wood powder and coupled laminate structure mineral powder to obtain composite wood powder; mixing the obtained composite wood powder, plastics and adjuvant; then extruding by using extruder so as to obtain the invented plastics wood composite special-purpose material.

Owner:TSINGHUA UNIV

Novel die for continuously extruding aluminum pipes, aluminum alloy pipes and special-shaped hollow profiles

InactiveCN101618408ASpeed up the flowReasonable structureExtrusion diesEconomic benefitsAluminium alloy

The invention relates to a novel die for continuously extruding aluminum pipes, aluminum alloy pipes and special-shaped hollow profiles, comprising a die arranged in a cavity in an integral structure. A front deflector of the die, which is provided with at least three special-shaped shunt holes, is connected with an upper die of the die; the shunt holes of the front deflector form an inclined angle; a die core arranged on the upper die forms the inside diameter of a pipe, and a lower die connected with the upper die is provided with a welding cavity and a mold; the shunt holes of the front deflector form the angle of 18-20 degrees; the upper die and the lower die of the die are positioned by pins and are connected by screws; the die is connected with the cavity by a locking nut; the diameters of the upper die and the lower die are from 60*52-0.1mm to 60*52+0.1mm; and the mold and the die core are made of hard alloy materials. The invention improves the production efficiency of the aluminum alloy extrusion pipes or the special-shaped profiles by approximate 15 percent, decreases the production cost, prolongs the service life longer than twice, can produce the aluminum alloy pipes and the special-shaped profiles in various shapes and specifications and has good product quality and wide economic benefits.

Owner:佛山市禅城区南庄兴顺精密模具有限公司

Method for preparing recrystallized silicon carbide product through plastic method

The invention discloses a method for preparing a recrystallized silicon carbide product through a plastic method. The recrystallized silicon carbide product is prepared from, by mass, 60-70 parts of silicon carbide coarse powder, 30-40 parts of silicon carbide fine powder, 1-3 parts of plasticizer and 1-3 parts of a lubricating agent, and the particle size of the silicon carbide coarse powder is 20-150 micrometers; the particle size of the silicon carbide fine powder is 0.2-2 micrometers. The method includes the following steps that silicon carbide coarse powder is subjected to ball-milling and shaping, and shaped silicon carbide coarse powder is obtained; the silicon carbide fine powder is subjected to wrapping treatment with a poly ethylene diamine solution, and modified silicon carbide fine powder is obtained; the modified silicon carbide fine powder and plasticizer are mixed to be uniform, the shaped silicon carbide coarse powder, water and the lubricating agent are added, kneading is conducted, and plastic silicon carbide sludge is obtained; the plastic silicon carbide sludge is squeezed, wet greens are obtained and then dried, and green bodies are obtained; the green bodies are sintered and output out of a furnace, and the recrystallized silicon carbide product is obtained. The volume density of the recrystallized silicon carbide product is 2.5-2.65 g / cm<3>, and the bending strength at the room temperature is 80-110 MPa; compared with a slip casting method, production efficiency is high, the cycle is short, the cost is low, homogeneity of the product is good, and reliability is high.

Owner:HUNAN UNIV

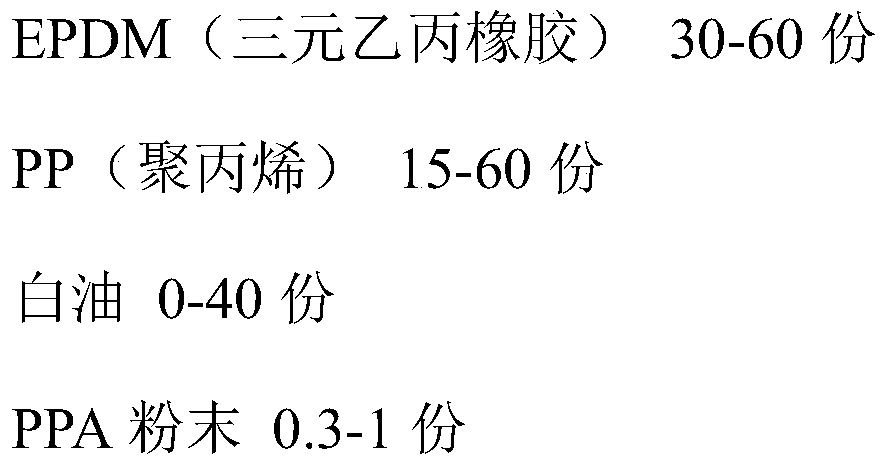

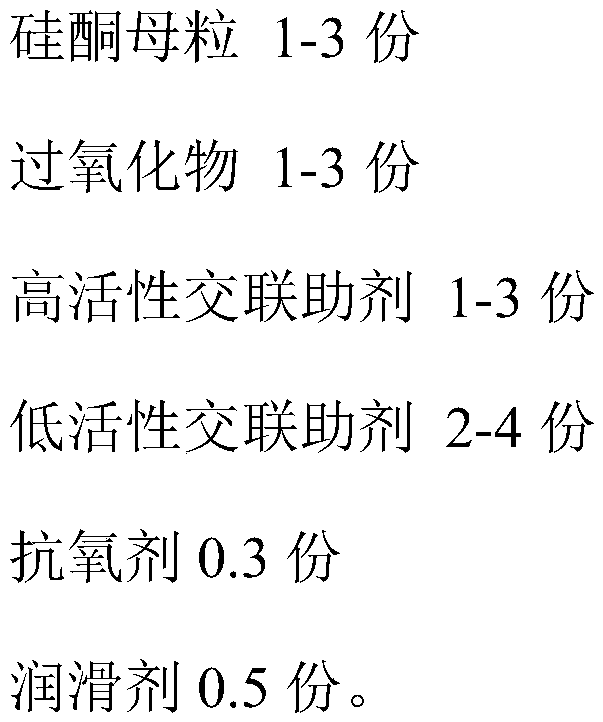

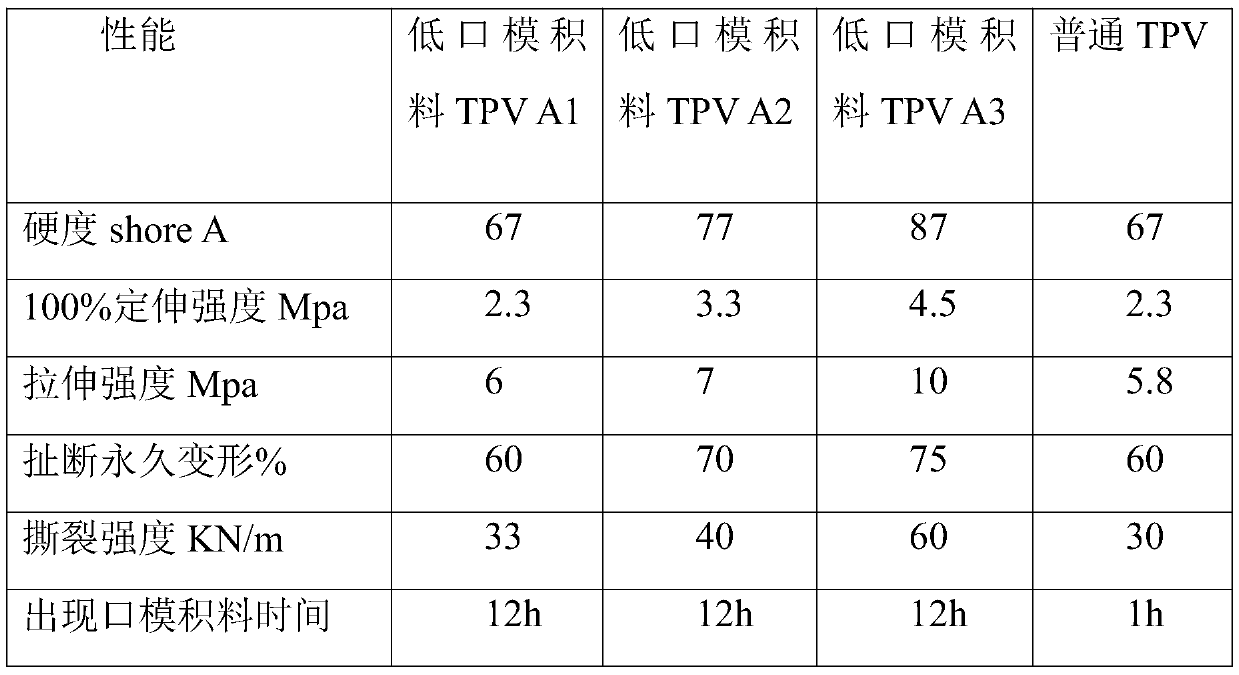

Low mouth die accumulated material polyolefin alloy thermoplastic elastomer and manufacturing method thereof

The invention discloses a low mouth die accumulated material polyolefin alloy thermoplastic elastomer and a manufacturing method thereof. EPDM (ethylene propylene diene monomer), PP (polypropylene), white oil, PPA (phenylpropanolamine) powder, silicone master batches, peroxide, high-activity crosslinking agents, low-activity crosslinking agents, antioxidants and lubricants are granulated by two-step double screws to prepare the elastomer, and the resistance of a die orifice in extrusion is reduced. Besides, by compound use of the crosslinking agents, the crosslinking degree of products is improved, and die swelling of the products is reduced, so that mouth die accumulated materials are reduced.

Owner:江苏金陵奥普特高分子材料有限公司

Functional material for removing nitrate nitrogen in water and preparation and application methods thereof

PendingCN112390380AImprove nitrogen removal efficiencyExtended service lifeWater contaminantsTreatment with anaerobic digestion processesFiberDolostone

The invention discloses a functional material for removing nitrate nitrogen in water and preparation and application methods thereof. The functional material is obtained by taking sulfur powder and high-activity iron-manganese sulfide powder as main raw materials and taking biomass fibers and a binder as additives, uniformly mixing the raw materials, adding water for molding, and then curing to finish hydration or carbonation. mixing functional material and limestone or dolomite particles and then fillinginto a biological filter, inoculating thiobacillus and culturing until a biological membrane is mature, and treating the wastewater in an upwelling mode according to the hydraulic retention time of 1-5h so that the removal rate of nitrate nitrogen in the wastewater reaches 80% or above.

Owner:HEFEI UNIV OF TECH

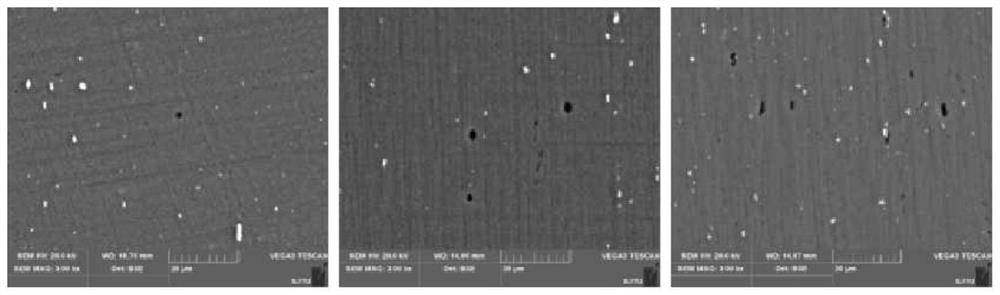

Processing method of self-lubricating phosphor copper ball extrusion die

InactiveCN110172549AHigh hardnessHigh hardness high strengthSolid state diffusion coatingSulfideQuenching

The invention provides a processing method of a self-lubricating phosphor copper ball extrusion die. The processing method of the self-lubricating phosphor copper ball extrusion die is a method of using a series of treatment processes of 4Cr5MoSiV1(H13) normalizing, tempering, quenching, deep cooling, sulfur carbonitriding and the like for performing self-lubricating treatment on a die for extrusion of copper balls. By using the processing method of the self-lubricating phosphor copper ball extrusion die, the die is high in internal hardness and strength, carbide and nitride of ferrum, molybdenum and chromium are generated on the surface of the die, and simultaneously molybdenum and ferrum sulfide is generated. The die is small in deformation and stable in shape due to the high hardness and the high strength of the die, and the carbide and the nitride which are generated on the surface of the die have high hardness, and therefore the die has good wear-resisting performance under supporting of a high strength and high hardness substrate. Furthermore, the molybdenum and ferrum sulfide is of laminar structure, and thereby has good oil storage and lubricating functions, reduces extrusion resistance, and prolongs life of the die.

Owner:JINCHUAN GROUP LIMITED

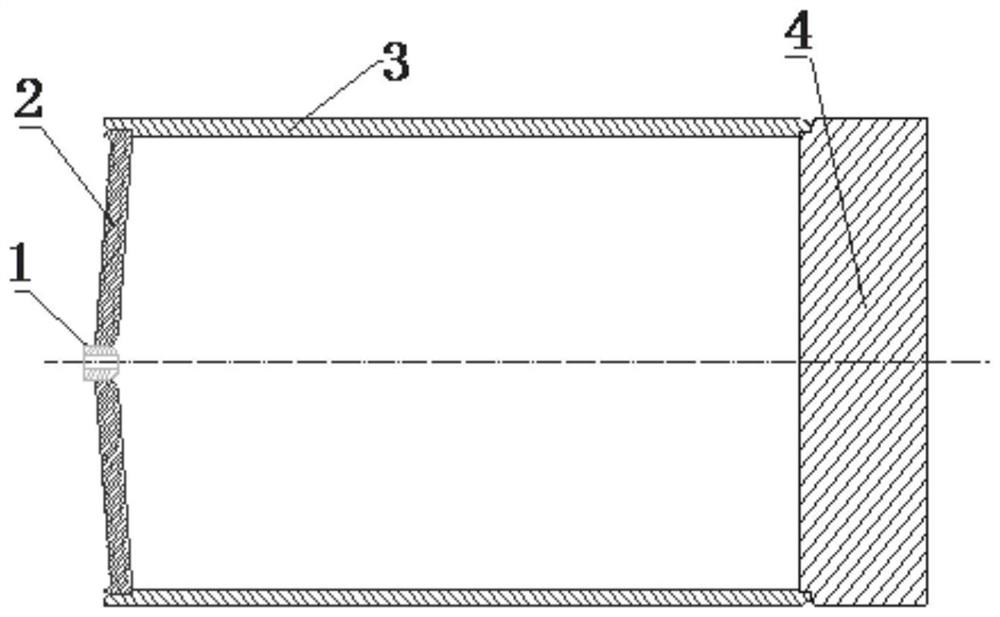

Powder high-temperature alloy horizontal extrusion integrated sheath and manufacturing method thereof

PendingCN112077324AReduce temperature dropReduce wasteBlade accessoriesMachines/enginesIngotSuperalloy

The invention belongs to the technical field of powder high-temperature alloy, and relates to a powder high-temperature alloy horizontal extrusion integrated sheath and a manufacturing method thereof.The integrated sheath consists of a powder nozzle, a sheath upper cover, a sheath outer wall and a sheath tail pad, and all the components are made of stainless steel and are welded; and vacuum annealing is carried out after welding, so that the sealing performance of the sheath is guaranteed, and air leakage of the sheath in a powder treatment and hot isostatic pressing implementation process isprevented. The sheath can be used as a powder sheath, and hot isostatic pressing is carried out after treated powder is filled, so that densification of the high-temperature alloy powder is realized;the sheath can also be used as a sheath of a subsequent hot extrusion process, a heat preservation effect is achieved in the extrusion process, temperature drop of a high-temperature alloy ingot blank body is reduced, and the extrusion resistance is reduced; the sheath tail pad is additionally arranged, and can be used as an extrusion blank for pressing, so that the waste of the powder high-temperature alloy is reduced; and meanwhile, the integrated design is adopted to simplify the manufacturing process of the sheath, so that the cost is reduced, and meanwhile, the extrusion stability is improved.

Owner:AVIC BEIJING INST OF AERONAUTICAL MATERIALS

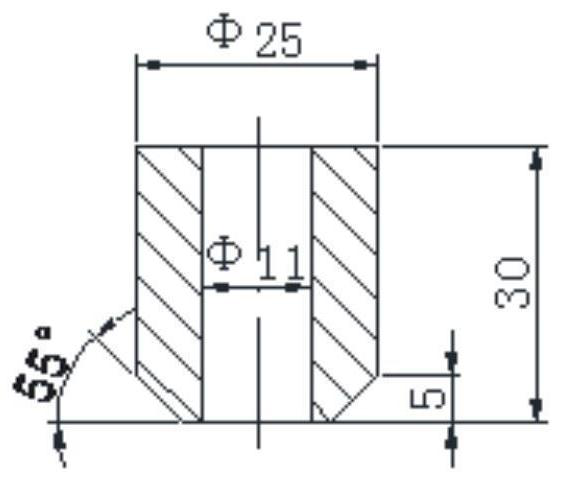

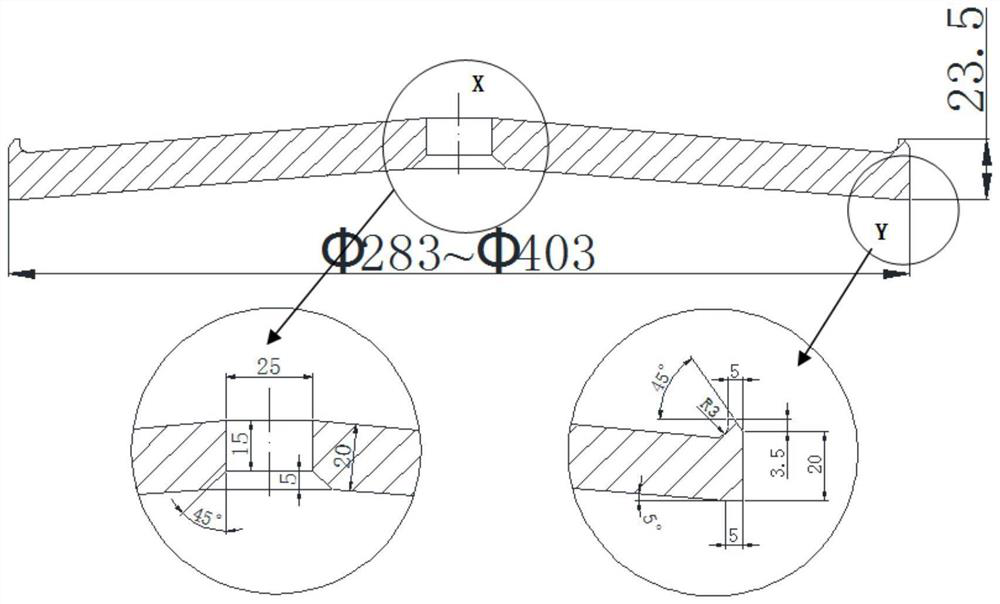

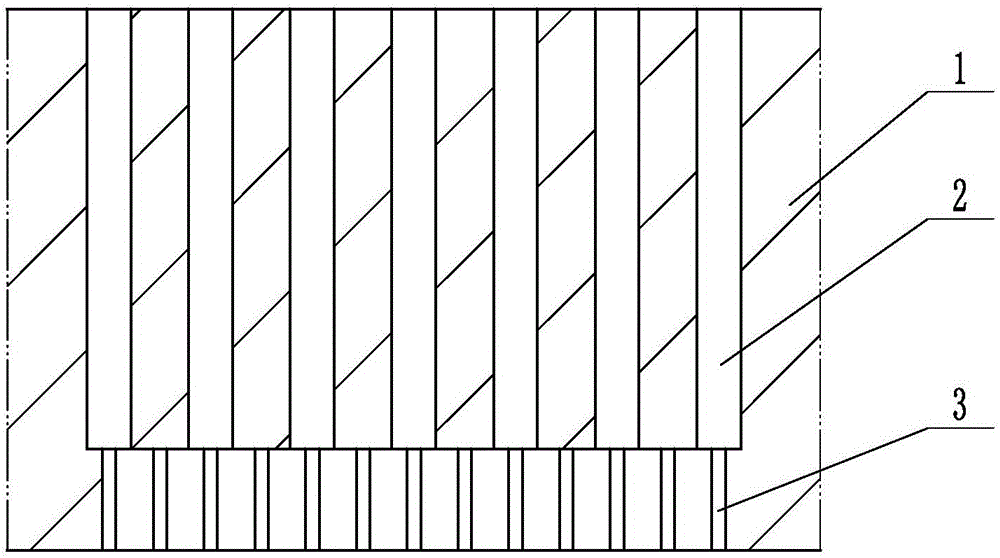

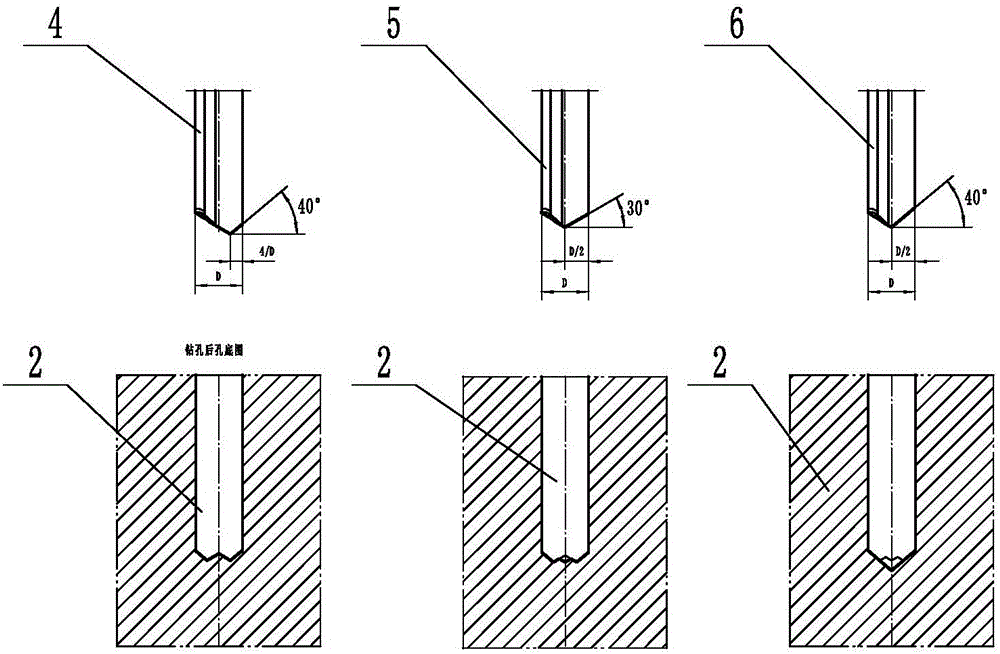

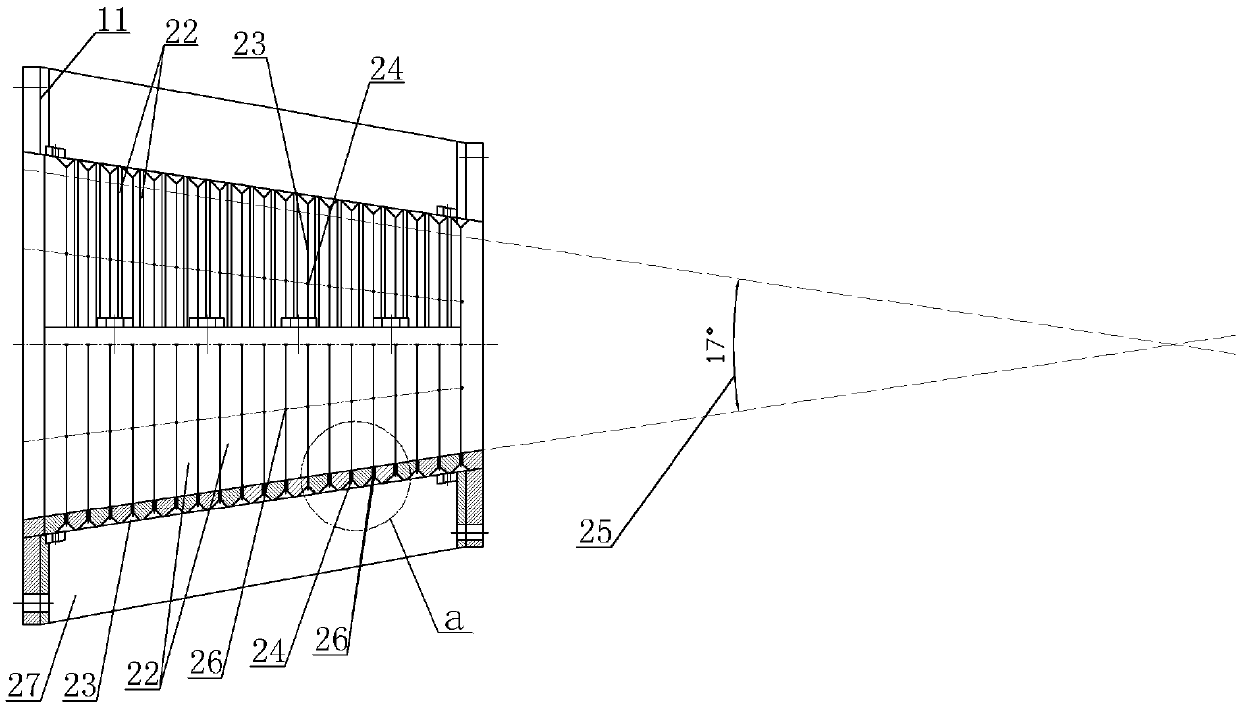

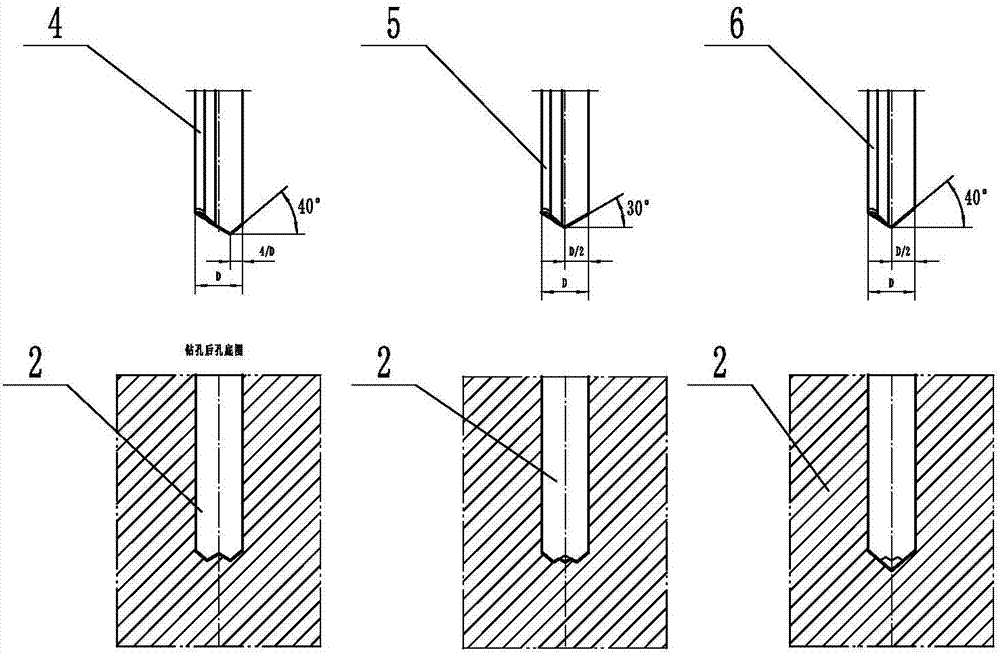

Manufacturing method for thin-wall large-specification honeycomb ceramic carrier die capable of being repeatedly coated

The invention relates to a manufacturing method for a thin-wall large-specification honeycomb ceramic carrier die capable of being repeatedly coated. The carrier die comprises a main die. The main die is provided with a plurality of feeding holes and discharging grooves corresponding to the feeding holes. The manufacturing method comprises the steps that a die plate blank is manufactured through die steel or other alloy steel; a feeding hole drilling machining program is compiled, and drilling is conducted through a numerical control deep hole drill; a linear cutting machining program is compiled, and the discharging grooves are machined on a linear cutting machine tool; pre-extrusion is conducted on an extrusion machine, and the inner surfaces of the feeding holes and the inner surfaces of the discharging grooves are ground to remove burrs and to be polished; the surfaces of the feeding holes of the carrier die and the surfaces of the discharging grooves of the carrier die are subjected to first-time coating machining; first-time batched honeycomb ceramic production is conducted through the coated carrier die, and after a certain number of ceramic blanks are extruded and formed, the feeding holes and the discharging grooves of the carrier die are subjected to second-time surface coating machining; and the carrier die subjected to second-time coating is utilized for conducting second-time batched production, and coating machining is conducted again after production.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY

Method and device for manufacturing cup-shaped component

InactiveCN103826772AReduce extrusion resistanceEasy to moveFriction clutchesGear wheelsMechanical engineeringTooth surface

The present invention relates to a method for manufacturing a cup-shaped component (7) in which an uneven part (721) is formed. The cup-shaped component (7) comprises a bottom part (71), and a cylindrical part (72). The cylindrical part (72) comprises the uneven part (721) which comprises a small diameter part (722), a large diameter part (723), and a tooth surface part (724). The present invention comprises a drawing process in which a material is processed into a cup shape, a preliminary processing process in which a preliminary uneven part (73) is formed, and a finishing process in which the uneven part (721) is formed. In the preliminary processing step, the width dimension (W2) of a preliminary large diameter part (731) is made to be larger than the width dimension of the large diameter part (723) of the uneven part (721).

Owner:AISIN AW CO LTD

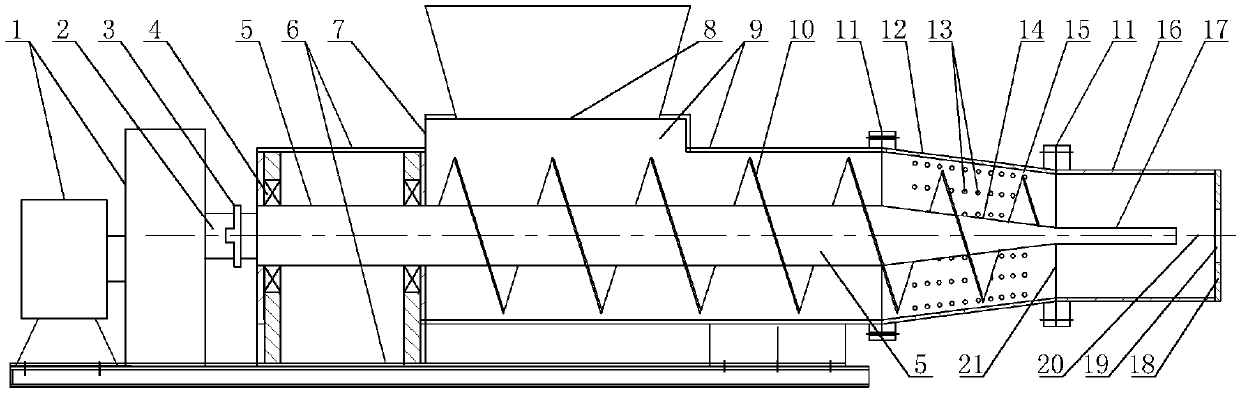

Straw dehydration extrusion forming machine

A straw dehydration extrusion forming machine is used for dehydrating and processing smashed straw into block materials, and is provided with a machine frame; an auger and a material pressing pipelineare installed on the machine frame; the material pressing pipeline is composed of a material pipe and a conical pipe, the material pipe is provided with a feeding inlet, one end of the material pipeis a blind end, the opening of the other end of the material pipe is connected with a flaring flange of the conical pipe, the narrow opening end of the conical pipe is a discharging outlet, and the pipe wall of the conical pipe is provided with a plurality of gas-liquid discharging holes; and the auger is provided with a main shaft, one end of the main shaft is rotationally connected to the machine frame, the other end of the main shaft is arranged in the material pressing pipeline, a shaft body of the main shaft is fixedly connected with a spiral rib sheet, and the axis of the main shaft coincides with that of the conical pipe. The straw block materials which are high in density, small in size and low in water content can be obtained by processing the smashed straw through the straw dehydration extrusion forming machine and can be directly used as fuel for a power plant, storing and transporting are facilitated, and the recycling cost of the straw is reduced.

Owner:磐石市富元机械厂

Large-size hollow ingot and ingot casting method

ActiveCN112430767AImprove final performanceImprove uniformityCasting cleaning apparatusIngot castingMaterials science

The invention belongs to the technical field of aluminum alloy, and particularly relates to a large-size hollow ingot and an ingot casting method. The large-size hollow cast ingot comprises the following chemical components of, in percentage by mass, less than or equal to 0.4% of Si, less than or equal to 0.4% of Fe, less than or equal to 0.1% of Cu, 0.7%-1.1% of Mn, 5.5%-6.5% of Mg, less than orequal to 0.1% of Cr, less than or equal to 0.04% of Ni, less than or equal to 0.2% of Zn, less than or equal to 0.15% of Ti, 0.001%- 0.005% of Be, 0.05%-0.15% of Zr, less than or equal to 10 ppm of Na, less than or equal to 10 ppm of Ca, and the balance Al and inevitable impurity elements, wherein the mount of Fe is larger than that of Si, and m% (Fe-Si) equal to 0.06%-0.1%. The casting method comprises the steps of compounding ingredients, smelting purification, casting and homogenizing treatment. The method is characterized in that an optimal melt purification process is determined by researching a feeding structure, a smelting temperature, a refining medium, refining gas and an operation mode; a cracking tendency defect is overcome by selecting the optimal casting temperature and casting speed; through a two-stage homogenizing treatment process, the structure uniformity is ensured, the deformation uniformity is promoted, recrystallization is inhibited, and the final performance of the alloy is improved; and an electromagnetic coil is added to achieve transformation and upgrading of a casting tool, external field assistance is provided, and large-size casting rods are easy to cast and form.

Owner:山东兖矿轻合金有限公司

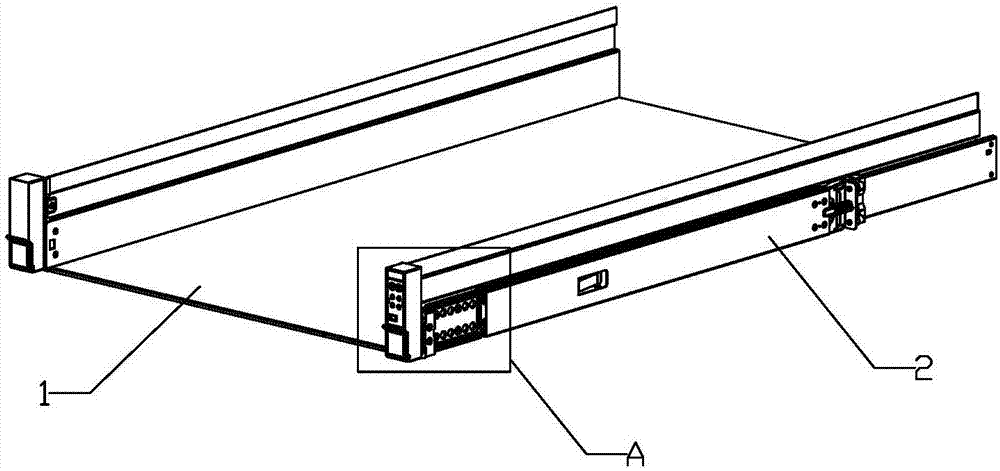

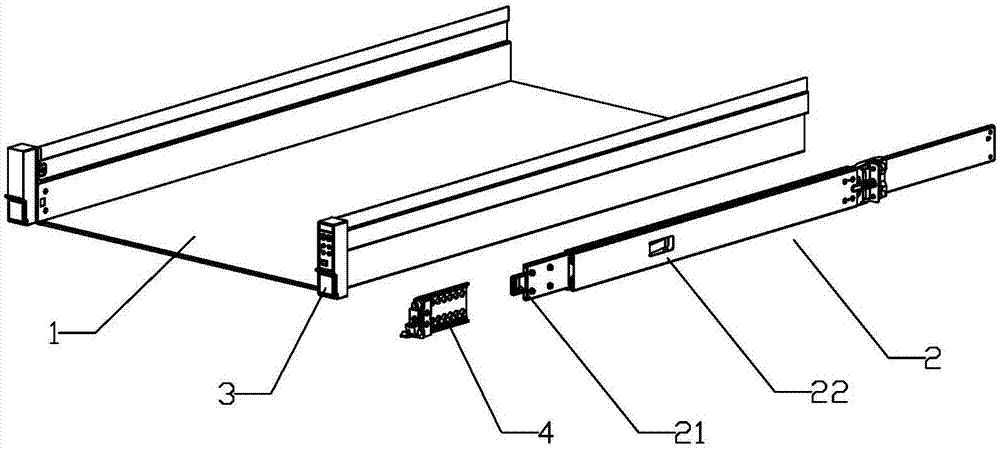

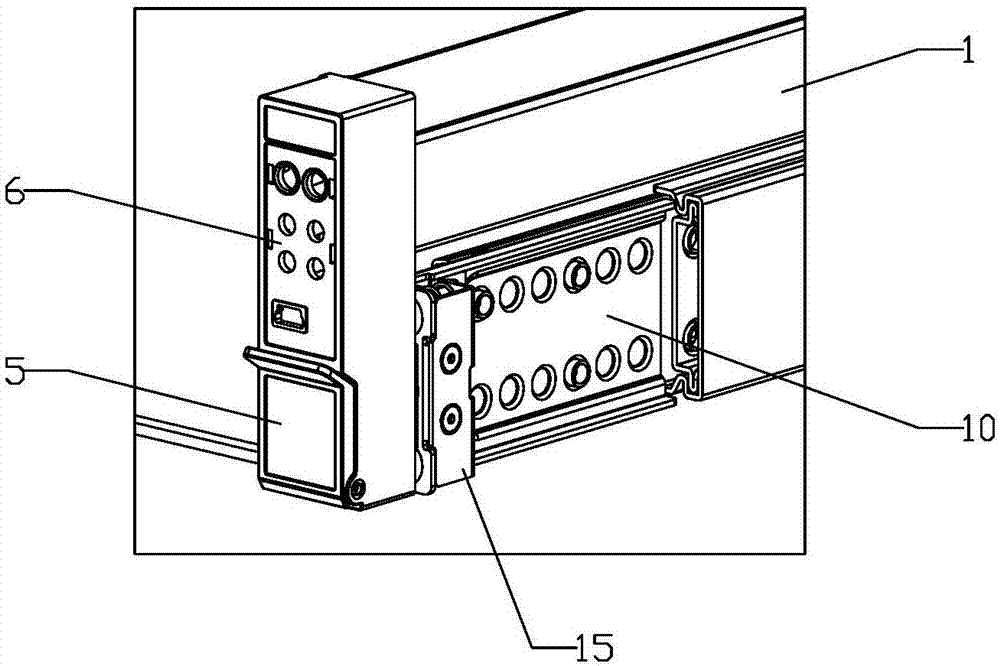

Server slide rail with automatic buckling device

InactiveCN106942921AReduce extrusion resistanceReduce resistanceDrawersEngineeringMechanical engineering

The invention relates to a server slide rail with an automatic buckling device. The server sliding rail comprises a drawer cabinet body and a slide rail assembly, wherein the slide rail assembly comprises an inner rail and an outer rail, wherein the inner rail relatively slides on the outer rail and the inner rail is connected with the drawer cabinet body; the automatic buckling device is arranged between the drawer cabinet body and the slide rail assembly; the automatic buckling device comprises a lock catch assembly arranged on the drawer cabinet body and a buckling assembly arranged on the outer rail; the lock catch assembly and the buckling assembly are mutually locked or unlocked; the lock catch assembly comprises an elastic resetting and rotary buckling block; the buckling assembly comprises a clamping hook, a movable block and a fixed block; when the slide rail assembly is closed, mutual line contact between the buckling block and the clamping hook is converted into mutual face contact and the buckling block and the clamping hook are finally buckled; the buckling block is driven to be released from the clamping hook and the sliding rail assembly is unlocked; the clamping hook is arranged on the movable block and the fixed block is arranged on the outer rail; the movable block is elastically pressed on the fixed block. According to the server sliding rail with the automatic buckling device, the line contact is converted into the face contact, so that an acting force is reduced, buckling resistance is reduced and automatic buckling is easily realized.

Owner:JIANGSU SACA PRECISION TECH CO LTD

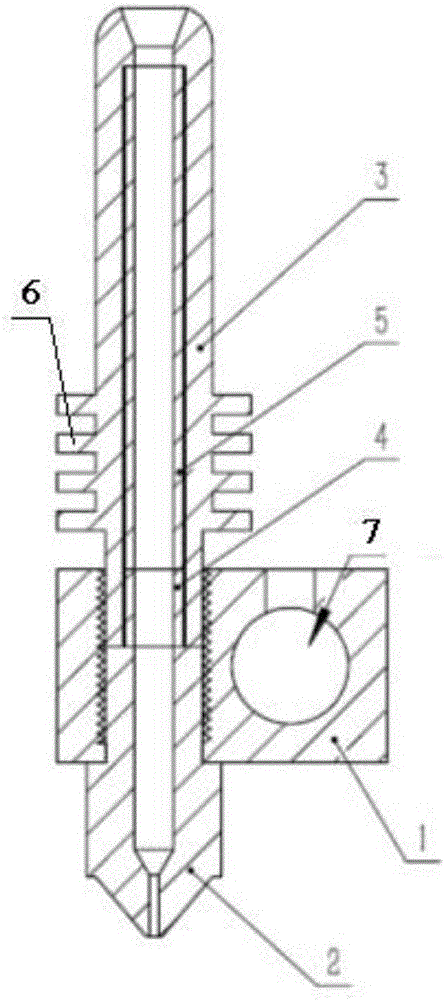

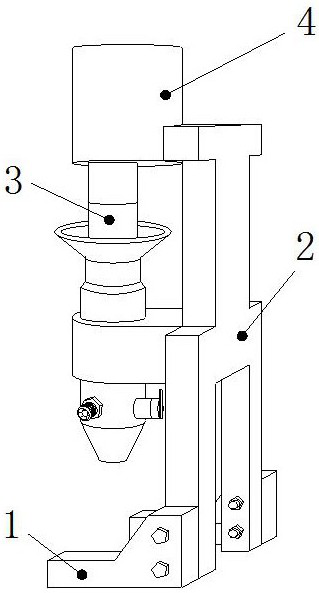

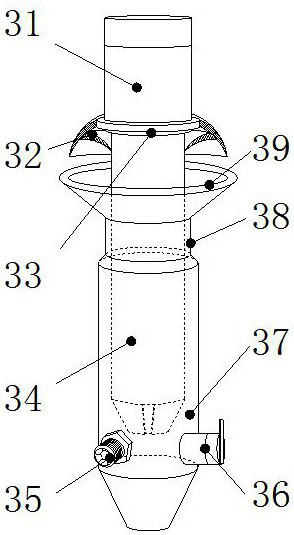

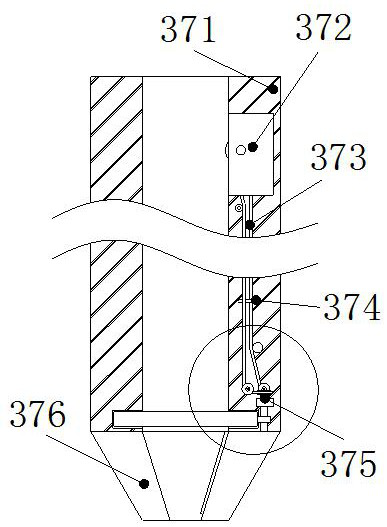

Extrusion spray-head structure of FDM (Fused Deposition Modeling) 3D printer

InactiveCN105150542AReduce extrusion resistanceSlow heatingAdditive manufacturing apparatusEngineering3d printer

The invention provides an extrusion spray-head structure of an FDM (Fused Deposition Modeling) 3D printer. The extrusion spray-head structure comprises a heating block, a wire conduit and a nozzle, wherein the nozzle is arranged at the bottom end of the wire conduit; the heating block is arranged at the part in which the nozzle is connected with the wire conduit; a teflon tube is arranged in the wire conduit, and a stainless steel tube is arranged at the bottom end of the teflon tube and corresponding to the heating block in position; a radiator is arranged on the outer surface of the wire conduit. With the adoption of the spray-head structure, the temperature transferred from the nozzle to the wire conduit can be greatly decreased, so that the probability of melting thermoplastic materials can be reduced, and as a result, the fault in the wire conduit can be greatly reduced.

Owner:合肥中加激光技术有限公司

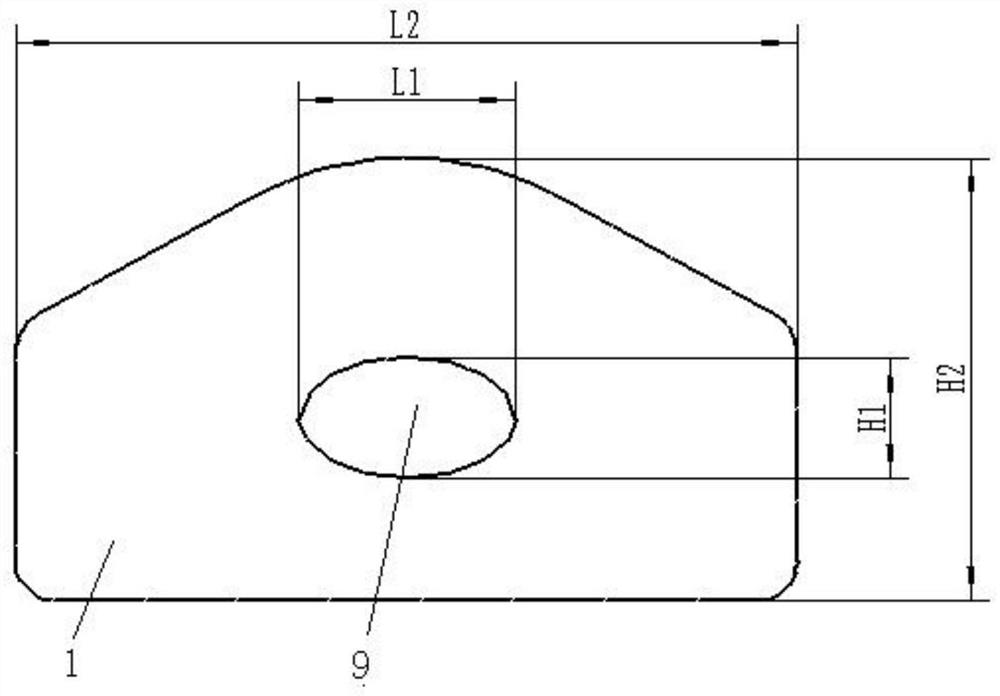

Machine head device used for forming and sintering exterior wall decorative hanging plate of extruder

ActiveCN106042152ATo break the problem of only a single production of bricks and tilesIncrease profitCeramic extrusion diesBrickEngineering

The invention provides a machine head device used for forming and sintering an exterior wall decorative hanging plate of an extruder. The machine head device is provided with a machine head housing, wherein one end of the machine head housing is fixedly connected to a machine body; the other end of the machine head housing is fixedly connected to a machine opening through a core rack; the machine head housing is in the shape of an oblate ellipsoid; the middle part of the machine opening is provided with a straight long-strip-shaped outlet; a plurality of core tools which are continuously arranged into one row are arranged in the straight long-strip-shaped outlet; a distributing guide post is arranged in a V-shaped inner cavity inside the machine head housing; and a plurality of rolling shafts which are continuously arranged in parallel and a water lubricating device are arranged on each of the upper inner wall and the lower inner wall of the machine head housing. The machine head device is connected to the machine head of a vacuum extruder, so that the exterior wall decorative hanging plate can be extruded, formed and sintered, the problem that a conventional extruder only can produce bricks and tiles is solved, a comprehensive utilization rate of equipment resource is promoted, and a product additional value is increased.

Owner:陕西皇城机械(集团)有限公司

Polymer melt shear vibration extrusion molding device

The invention provides a polymer melt shear vibration extrusion molding device which comprises an extruding machine 13, an extrusion head 1 connected with the extruding machine through a flange plate, a mouth mould 12, a stock mould 14, a cooling water tank 15, a traction device 16 and a cutting device 17, and is characterized by further comprising a crank connecting rod shear vibration system 18 and a melt runner vibration chamber 2, wherein the crank connecting rod shear vibration system 18 is arranged above the extrusion head 1; the melt runner vibration chamber 2 is arranged inside the extrusion head 1; the crank connecting rod shear vibration system is composed of a crank connecting rod mechanism and a reciprocating vibration rod 3; the reciprocating vibration rod 3 is positioned in a through hole 9 formed in the extrusion head 1; the through hole 9 is communicated with the melt runner vibration chamber 2. The device provided by the invention not only can simultaneously promote polymer molecule chain orientation, shish-kebab structure generation and polymer crystalline grain refinement, and improve mechanical property of products, but also can reduce extrusion resistance and improve production efficiency.

Owner:SICHUAN UNIV

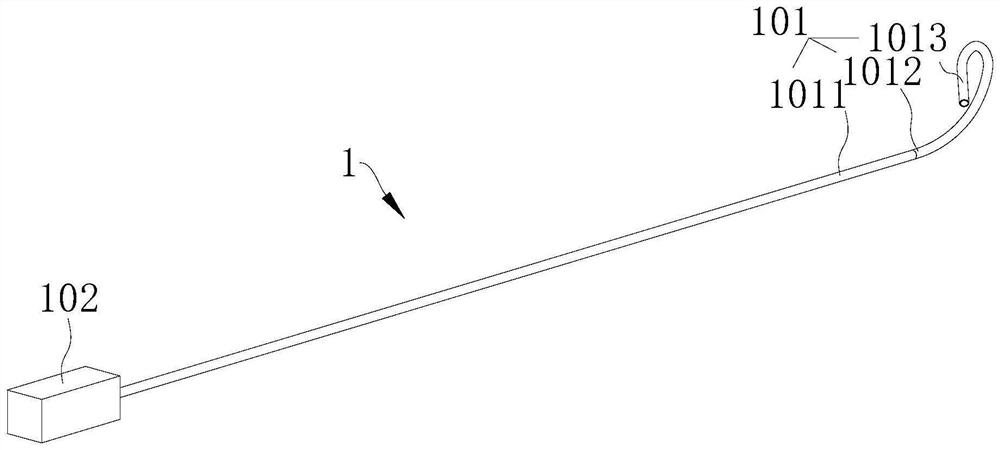

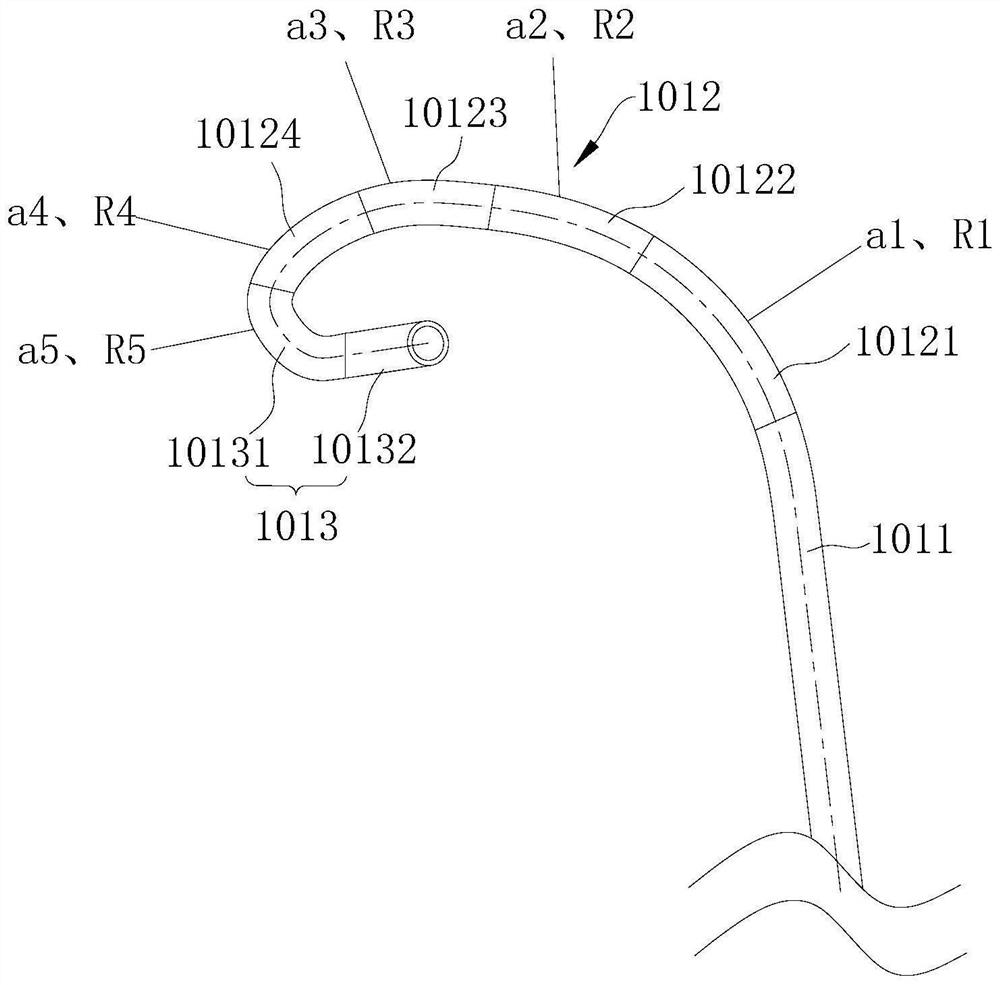

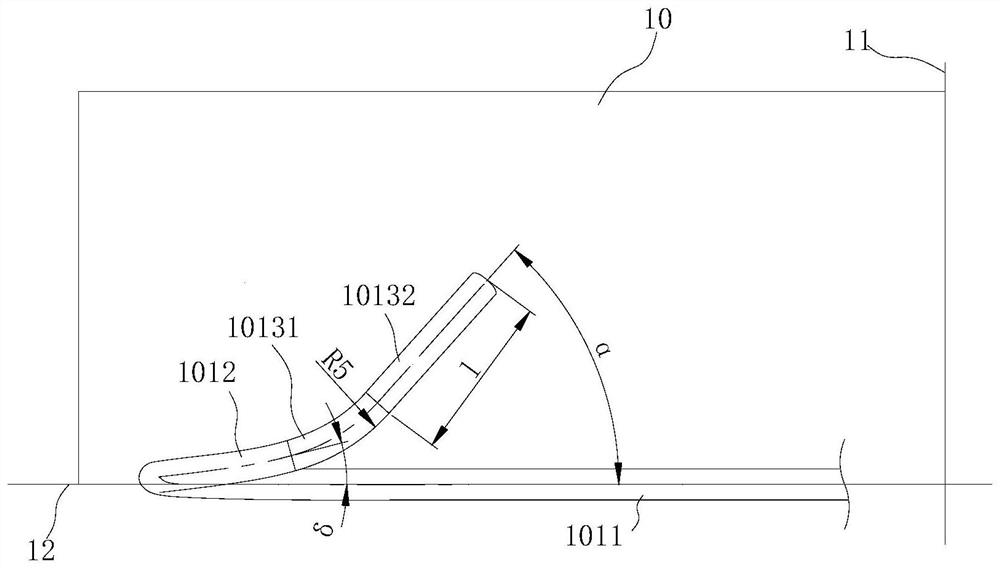

Self-adaptive guiding device and transcatheter treatment system

PendingCN114424972ASimple structureEasy to operateSurgical instruments for heatingNatural stateEngineering

The invention discloses a self-adaptive guiding device and a transcatheter treatment system.The self-adaptive guiding device comprises a hollow flexible catheter with a certain length, the flexible catheter is pre-shaped and bent towards different planes for at least five times along the central axis of the flexible catheter in the natural state, and the flexible catheter is bent towards the different planes along the central axis of the flexible catheter; the included angle between the two planes which are bent at a time and are closest to the far end is larger than 90 degrees, and the angle between the planes which are continuously bent at least four times is smaller than 90 degrees, so that at least part of the flexible tube body adapts to the shape of the aortic arch part. According to the self-adaptive guiding device and the transcatheter treatment system provided by the invention, the self-adaptability of the guiding device to blood vessels with complex anatomic forms such as the aortic arch part can be improved, the structure of the guiding device is simplified, and the use safety of instruments is improved; the situation that the guiding device needs a large avoiding space during use is avoided, tissue is prevented from entering an avoiding area in a filling mode, and it is ensured that the guiding device has a large operation adjusting space and an initial position which is more beneficial to adjustment.

Owner:DEKE MEDTECH HANGZHOU INC

Hot extrusion forming method of copper alloy rail

PendingCN112170523AReduce oxidationReduce extrusion resistanceExtrusion diesUltimate tensile strengthLubrication

The invention relates to a hot extrusion forming method of a copper alloy rail. The method includes the following steps that 1, blank processing is performed, specifically, (1) forged polished blank round steel is sawn; (2) the center of the blank is drilled; (3) turning machining and polishing of the outer surface and the head are performed; 2, blank heating is performed, specifically, the heating temperature ranges from 900 DEG C to 950 DEG C; 3, tool and mold preparation is performed, specifically, extrusion molds with the same shapes are adopted; 4, lubrication is performed, specifically,the extrusion molds, manipulators and extrusion cylinders are coated with lubricants; 5, hot extrusion is performed, specifically, hot extrusion forming is performed on the blank; 6, cooling is performed, specifically, the copper alloy rail is cooled to the room temperature; 7, solid solution heat treatment is performed, specifically, the heating temperature ranges from 930 DEG C to 950 DEG C; 8,inspection is performed, specifically, the hardness and the conductivity are inspected; 9, straightening is performed, specifically, the copper alloy rail is straightened; 10, cold drawing is performed, specifically, cold drawing is performed on the copper alloy rail; 11, aging heat treatment is performed; 12, the section hardness, conductivity and room-temperature tensile strength are inspected;and 13, straightening is performed. According to the method, one-time forming of the workpiece is guaranteed through optimization of the mold design and the extrusion forming process, the surface quality of the manufactured copper alloy rail is good, and the physical, chemical and mechanical properties of the product are improved.

Owner:HANDAN XINXING SPECIAL TUBING CO LTD

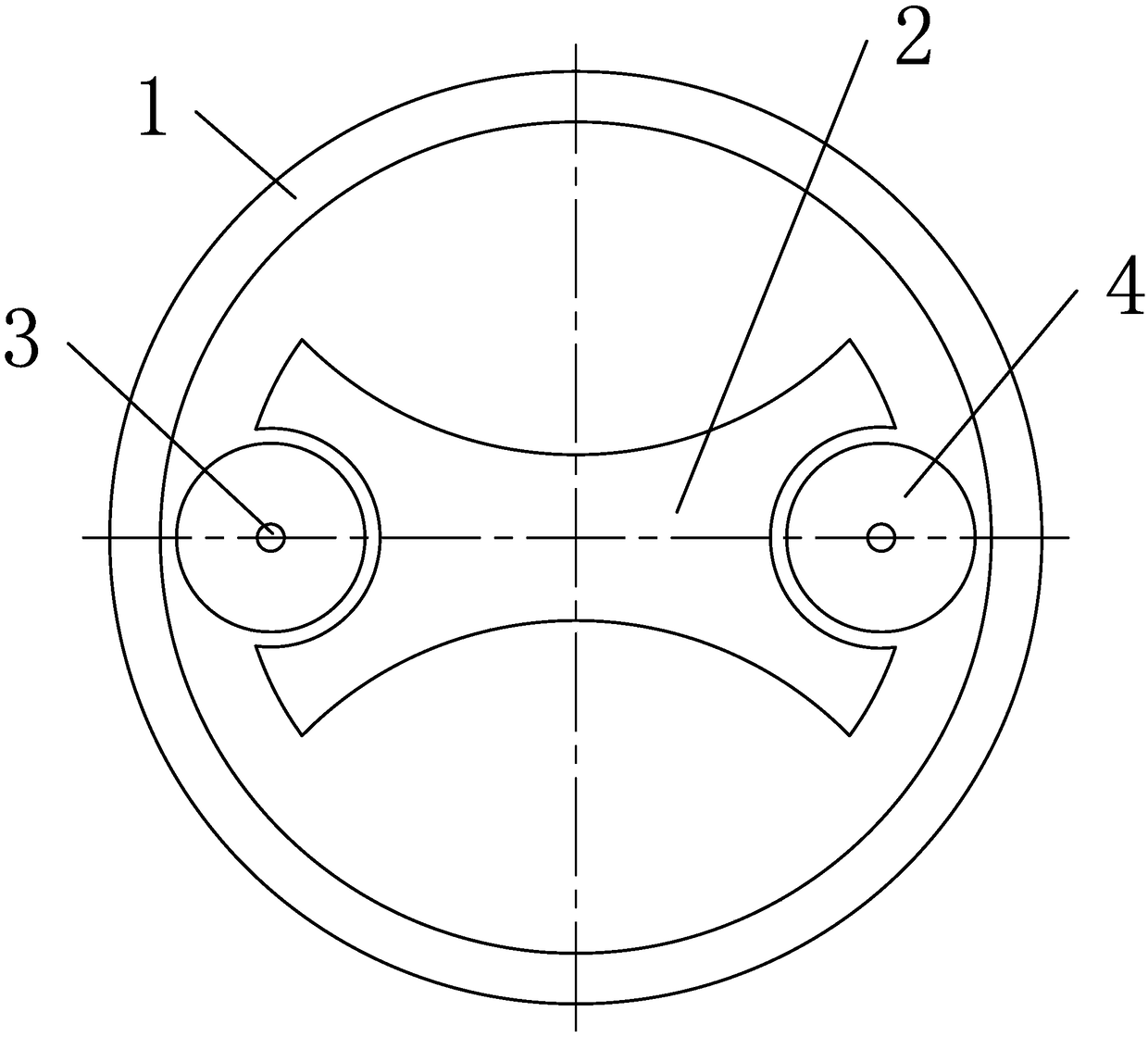

Granulating machine

PendingCN109126635AReduce stressSo as not to damageGranulation by pressingComing outElastic component

The invention provides a granulating machine with small stress of parts such as a ring die, stable load, long service life, low energy consumption, high yield and high production efficiency. The granulating machine comprises a machine base; two engaged gear ring dies are rotatably arranged on gear ring die shafts; one of the two gear ring die shafts is a fixed shaft, and the other one of the two gear ring die shafts is a floating shaft; the fixed shaft is fixed on the machine base; the floating shaft capable of moving relative to the fixed shaft in the radial direction is arranged on the machine base; an elastic component is arranged between the machine base and the floating shaft; a power mechanism for driving one gear ring die to rotate is arranged on the machine base; a die hole extending along a radial direction is formed in the each gear ring die; an inlet and an outlet of the die hole are formed in an outer ring and an inner ring of each gear ring die; a feeding channel is formedin the machine base; an outlet of the feeding channel is positioned on an engaged part of the outer rings of the two gear ring dies; and materials which enter from the feeding channel are pressed into the die hole by the two engaged gear ring dies from the die hole inlet and form material rods to come out of the die hole.

Owner:WUXI VOCATIONAL & TECHN COLLEGE +1

Manufacturing method of thin-walled large-scale honeycomb ceramic carrier mold that can be repeatedly coated

The invention relates to a manufacturing method for a thin-wall large-specification honeycomb ceramic carrier die capable of being repeatedly coated. The carrier die comprises a main die. The main die is provided with a plurality of feeding holes and discharging grooves corresponding to the feeding holes. The manufacturing method comprises the steps that a die plate blank is manufactured through die steel or other alloy steel; a feeding hole drilling machining program is compiled, and drilling is conducted through a numerical control deep hole drill; a linear cutting machining program is compiled, and the discharging grooves are machined on a linear cutting machine tool; pre-extrusion is conducted on an extrusion machine, and the inner surfaces of the feeding holes and the inner surfaces of the discharging grooves are ground to remove burrs and to be polished; the surfaces of the feeding holes of the carrier die and the surfaces of the discharging grooves of the carrier die are subjected to first-time coating machining; first-time batched honeycomb ceramic production is conducted through the coated carrier die, and after a certain number of ceramic blanks are extruded and formed, the feeding holes and the discharging grooves of the carrier die are subjected to second-time surface coating machining; and the carrier die subjected to second-time coating is utilized for conducting second-time batched production, and coating machining is conducted again after production.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY

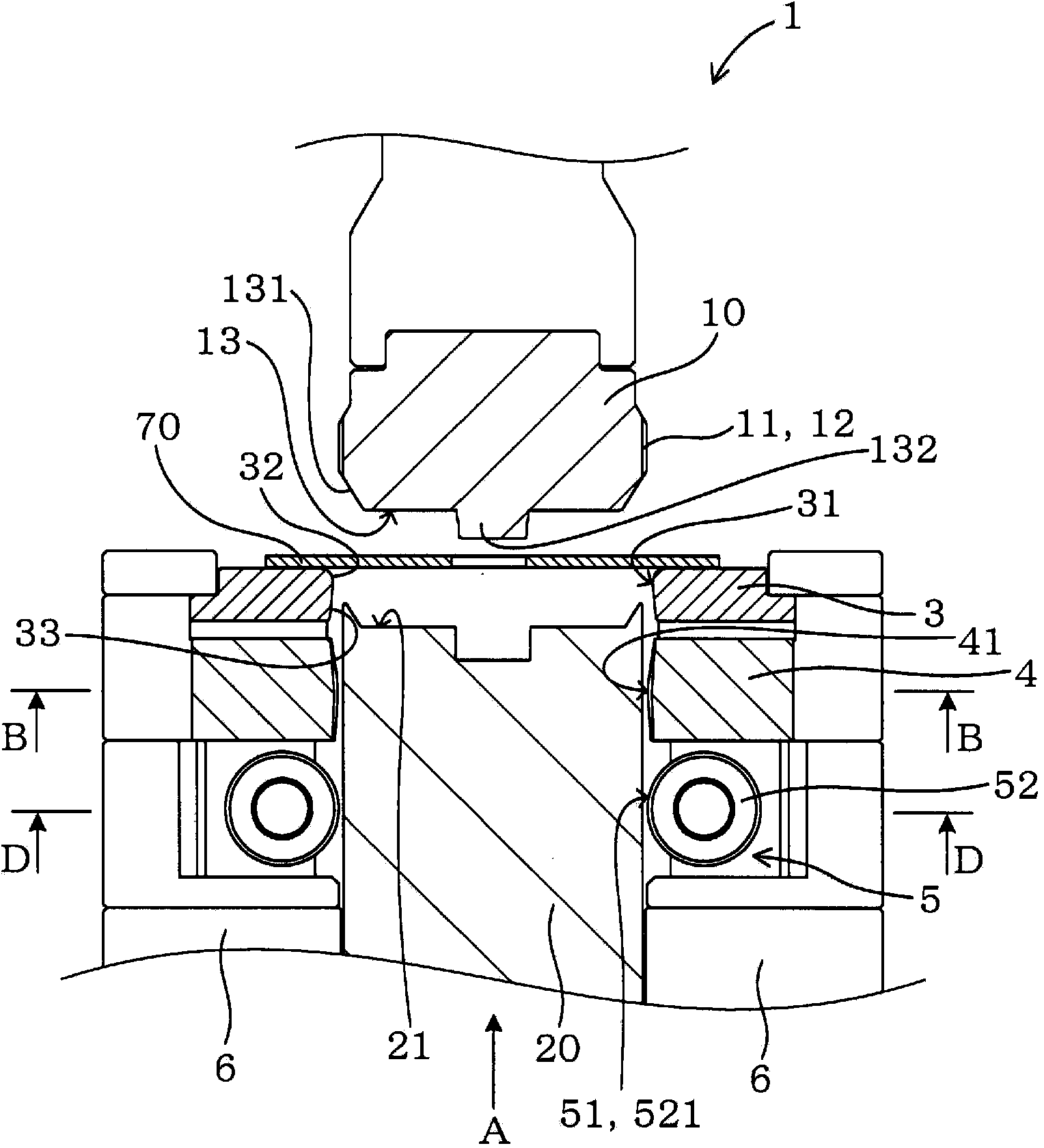

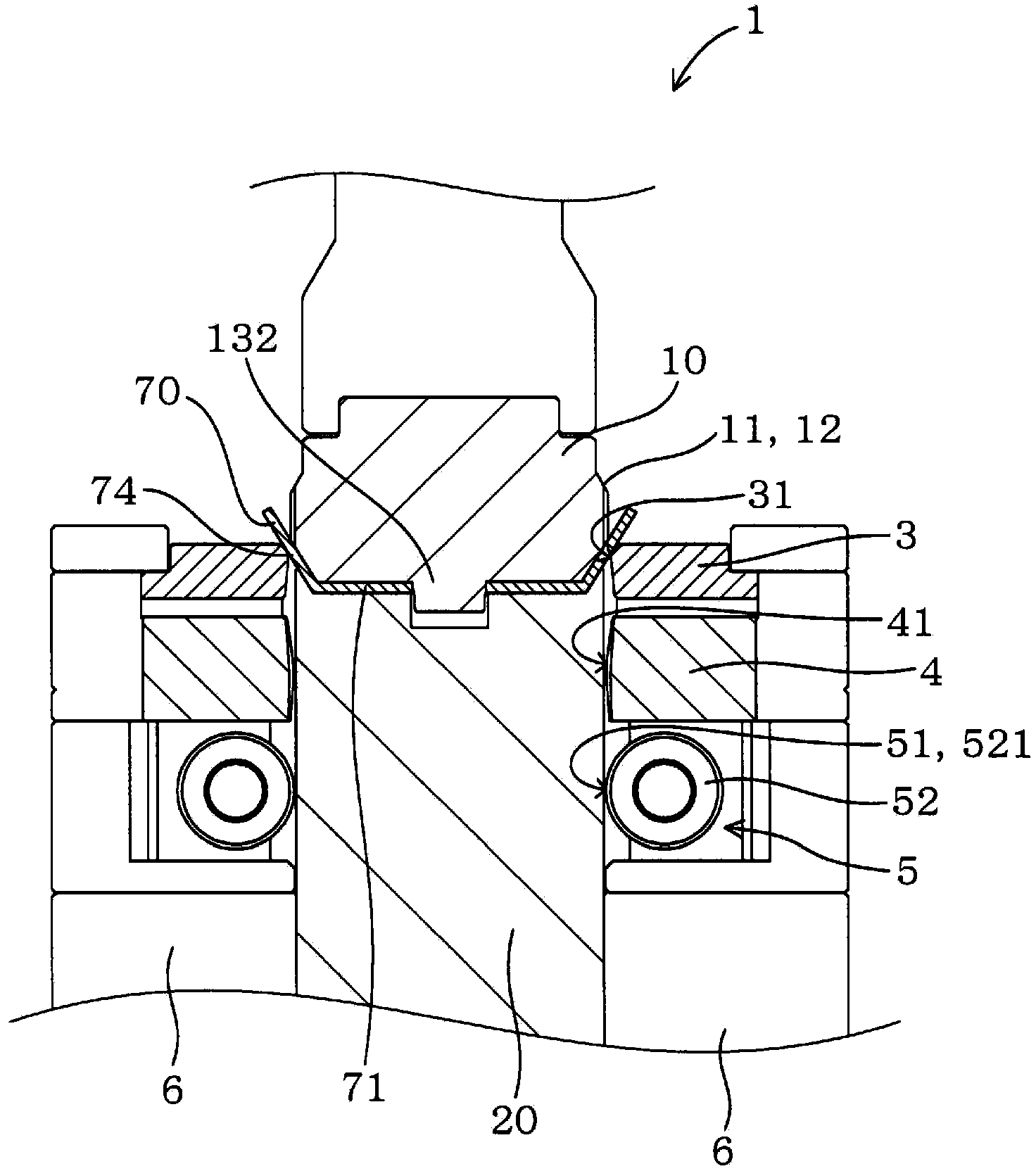

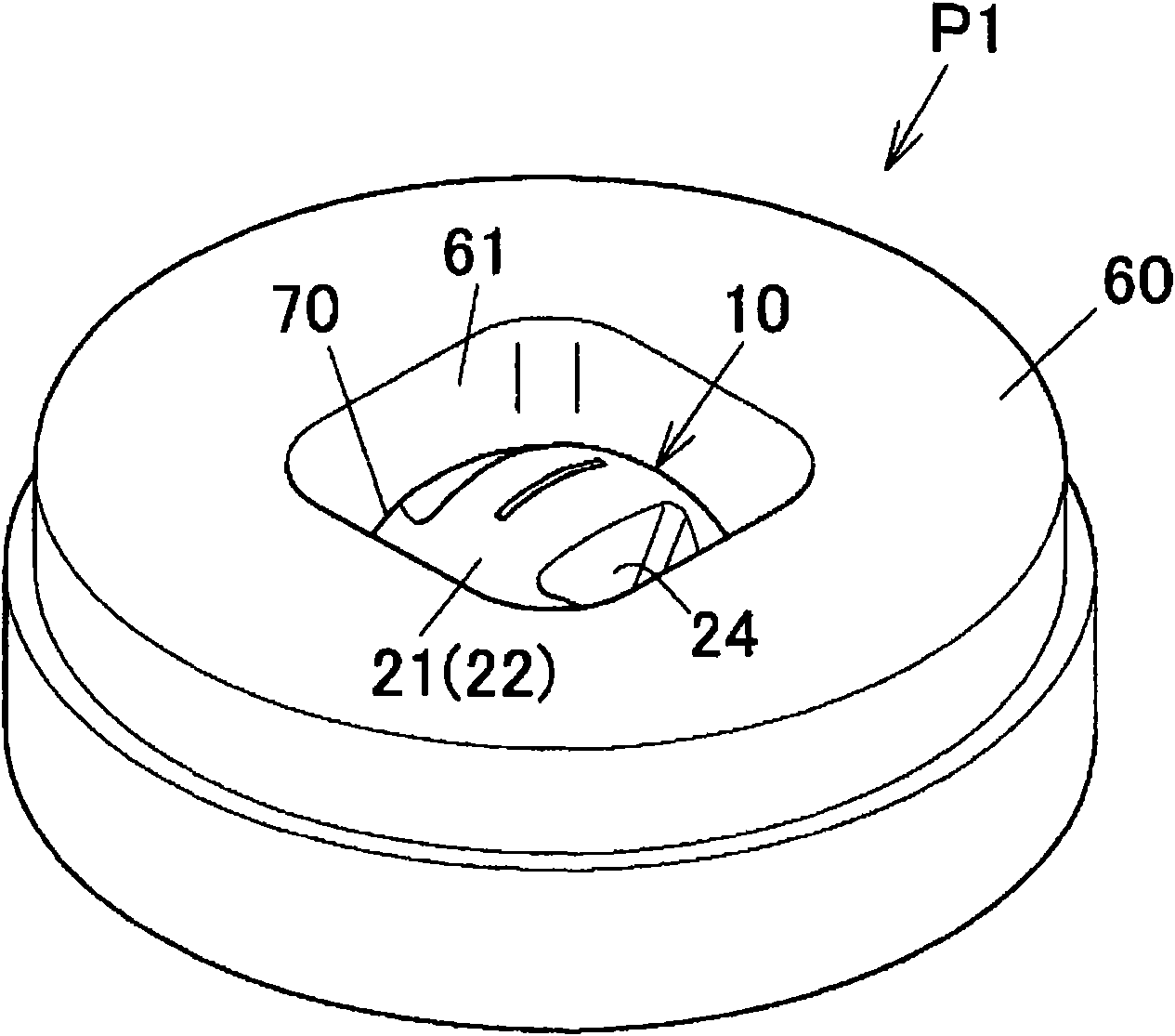

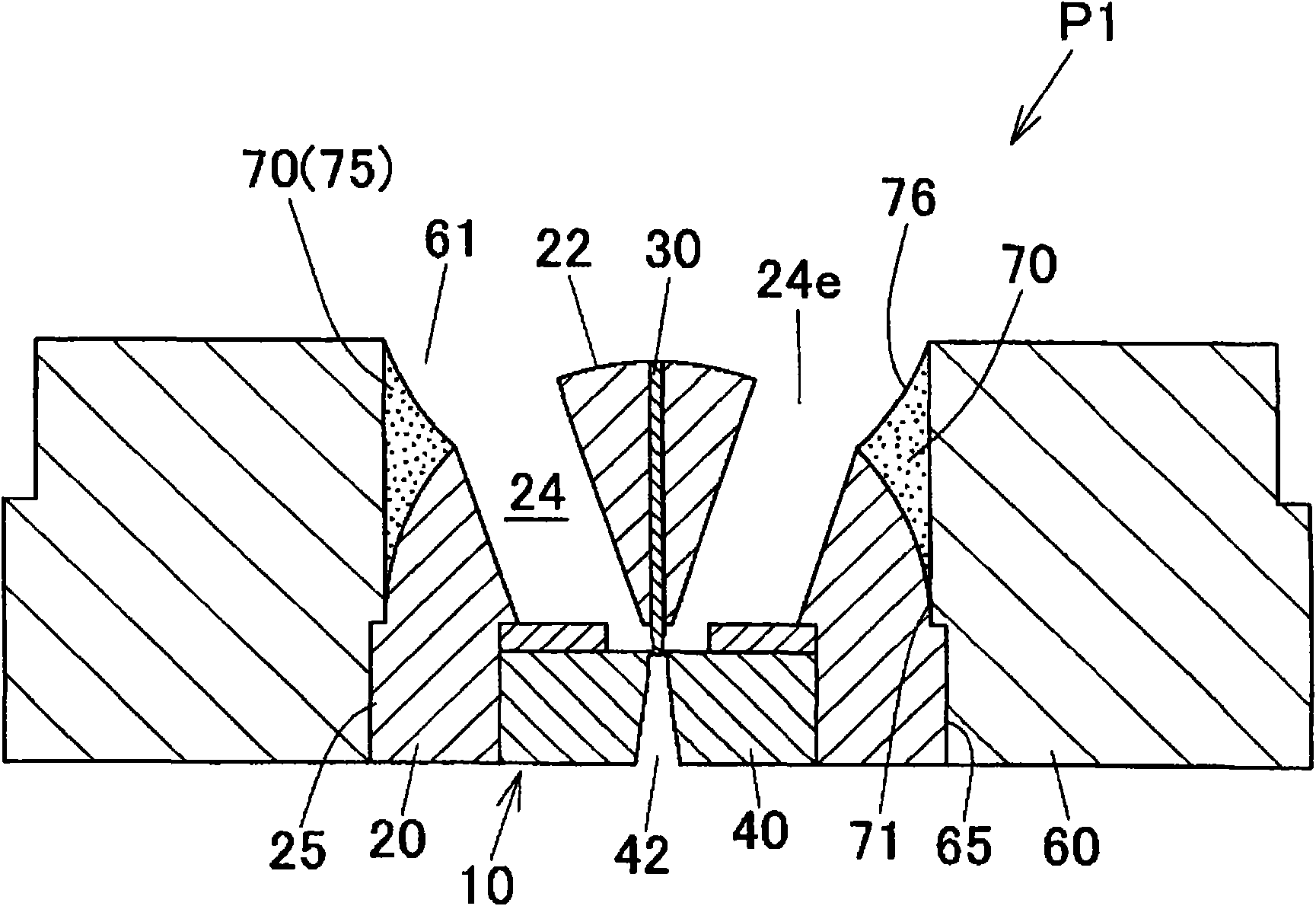

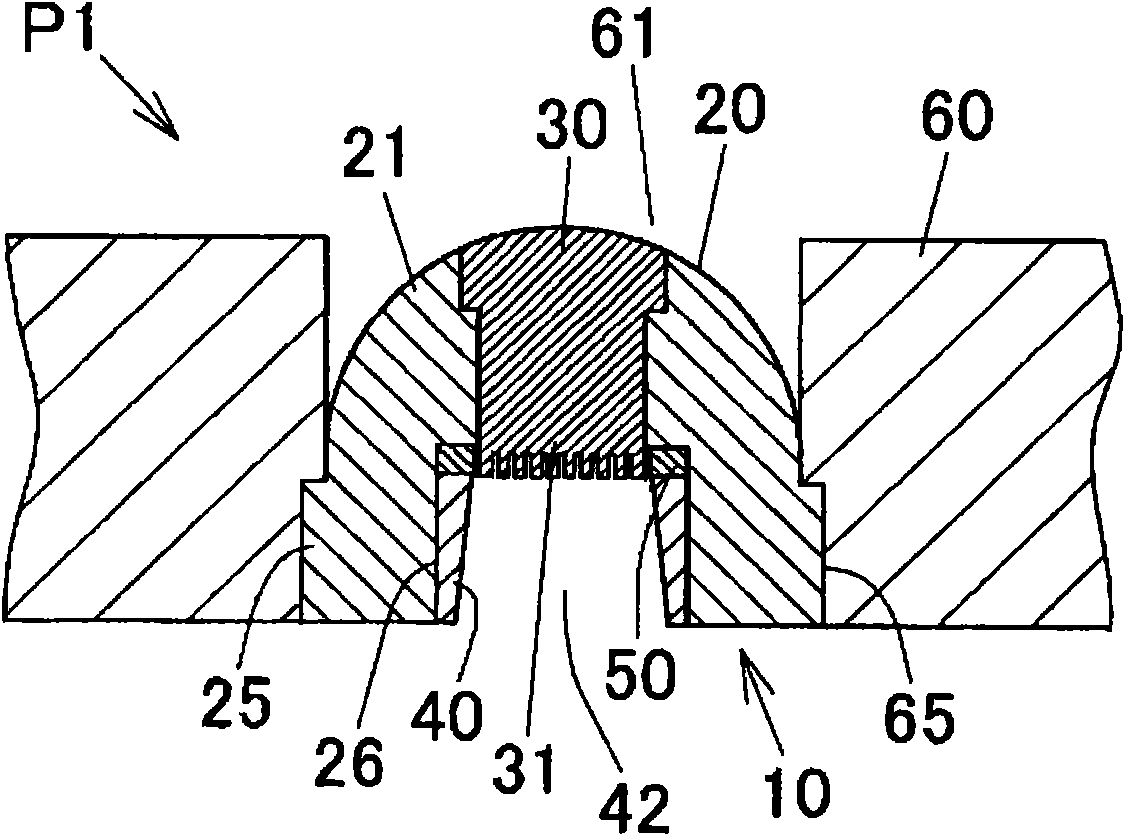

Die assembly tool for extrusion molding

InactiveCN101578145AImprove pressure resistanceIncreased durabilityExtrusion diesMetallic materialsEngineering

A die assembly tool (P1) is constructed such that an extrusion molding die (10) is placed in a die installation hole (61) of a die installation plate (60) and that a metal material introducing into the die installation hole (61) is introduced from a port hole (24) formed in a metal material pressure receiving surface (22) of the die (10). A material containing section (70) reaching the downstream side, in the extrusion direction, of the inlet position of the port hole (24) is provided outside the port hole (24).The assembly tool (P1) is adapted such that a portion (75) of the metal material introduced into the die installation hole (61) is contained in the material containing section (70).

Owner:SHOWA DENKO KK

Refractory ceramic plunger machine

The invention discloses a refractory ceramic plunger machine. The refractory ceramic plunger machine structurally comprises a support foot, a supporting frame, a plunger device and a driver, wherein the right end of the support foot is connected with the lower end of the supporting frame through bolts, and the driver is connected with the upper end of the plunger device through a shaft. The rotation of a rotating ring can scrape and clean the ceramic mud on the inner wall of an extrusion port, a large amount of porcelain clay is prevented from adhering on the surface of the outer side of the extrusion port, after using, it is necessary to reach into the interior for cleaning so as to prevent the situation that it is difficult to clean the ceramic mud on the surface of the inner wall of theextrusion port due to air drying, thus a certain dangerousness exists, a supporting block in a ring body drives a connecting piece to rotate to close to the surface of the inner wall of the extrusionport to rotate to generate vibration, dried ceramic mud is conveniently vibrated to reduce the adhesion force with the inner wall of the extrusion port, finally, the dried ceramic mud is shaken off,and the situation that the dried ceramic mud has certain strength, under the condition of unclear cleaning, the extrusion port can be broken by extruding again, the extrusion resistance is reduced, and the extruded ceramic mud is unqualified is prevented.

Owner:衡阳阳光陶瓷有限公司

Aluminum profile extrusion die for frame

PendingCN108067517AUniform exit velocityGood weldabilityExtrusion diesEngineeringMechanical engineering

The invention relates to an aluminum profile extrusion die for a frame and belongs to the technical field of dies. The aluminum profile extrusion die for the frame comprises an upper die and a lower die, wherein the upper die and the lower die are connected through a positioning pin and a fastening screw; a die core is arranged in the middle of the upper die; seven dividing holes are formed aroundthe die core; three dividing holes on the upper side and four dividing holes on the lower sides are arranged adaptive to an aluminum profile structure; dividing bridges are arranged among the dividing holes; the dividing bridges are designed as tips, the inlet sections of which form included angles of 40 degrees; a welding chamber, a cavity and a discharge port are formed in the lower die; a primary welding chamber and a secondary welding chamber are arranged in the welding chamber; and a primary empty cutter and a secondary empty cutter are arranged at the discharge port. The welding effectof a metal flowing through the dividing holes is good, the outlet speed of the profile is uniform, and particles adsorbed to the surface of the aluminum profile are reduced.

Owner:CHIZHOU JIUHUA MINGKUN ALUMINUM IND

A production process of ultra-high-strength 7055 aluminum alloy profiles

ActiveCN107604275BHigh dimensional accuracySolve Squeeze Link Intermittent IssueHeating temperatureAluminium alloy

The invention belongs to the field of aluminum alloy hot extrusion, and relates to a ultrahigh-strength 7055 aluminum alloy profile production process. Through improvement of an extrusion mold, the size of a working tape is shortened from 18-28 mm to 13-25 mm, the extrusion breakthrough pressure is reduced from 25 bar to 19 bar; the heating temperature of a ultrahigh-strength 7055 aluminum alloy profile extrusion mold is maintained within 450+-10 DEG C in the extrusion process, and is kept invariable by 5 hours; the heating temperature of an extrusion cylinder is lowered from 420+-10 DEG C to410+-10 DEG C; the heating temperature of a cast rod is lowered from 420+-10 DEG C to 390+-10 DEG C; finally, the profile extrusion efficiency is improved from 0.3-0.5 m / min to 0.7-0.8 m / min; and through reasonable selection of an extruder and optical design of an extrusion mold and an extrusion process, profile products meeting United States standards are finally realized to replace foreign imports.

Owner:CHINA ZHONGWANG

Polymer alloy products containing intercrystalline bridge texture and processing method thereof

A polymer alloy product containing heterogeneous attached crystal inter-crystalline bridge tissue structure and its production are disclosed. The process is carried out by crystallized forming attached-phase polymer A on orientated basis-phase polymer B, staggered overlapping, and intersecting ordered lamellar crystal C axis with basis-phase polymer B lamellar crystal C axis. It consists of orientated basis-phase polymer B 50-99 wt% and attached-phased polymer A 1-50 wt%. It forms into ordered crystal reinforced intersected braiding structure. It has better binding strength between two interfaces, rigidity, ductility and stress resistance. It has less amorphous fault.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com