Granulating machine

A granulator and machine base technology, applied in the direction of mold extrusion granulation, etc., can solve the problems of pressure roller or ring die damage, low production efficiency, easy blockage, etc., to achieve long service life, high production rate, extrusion The effect of small pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

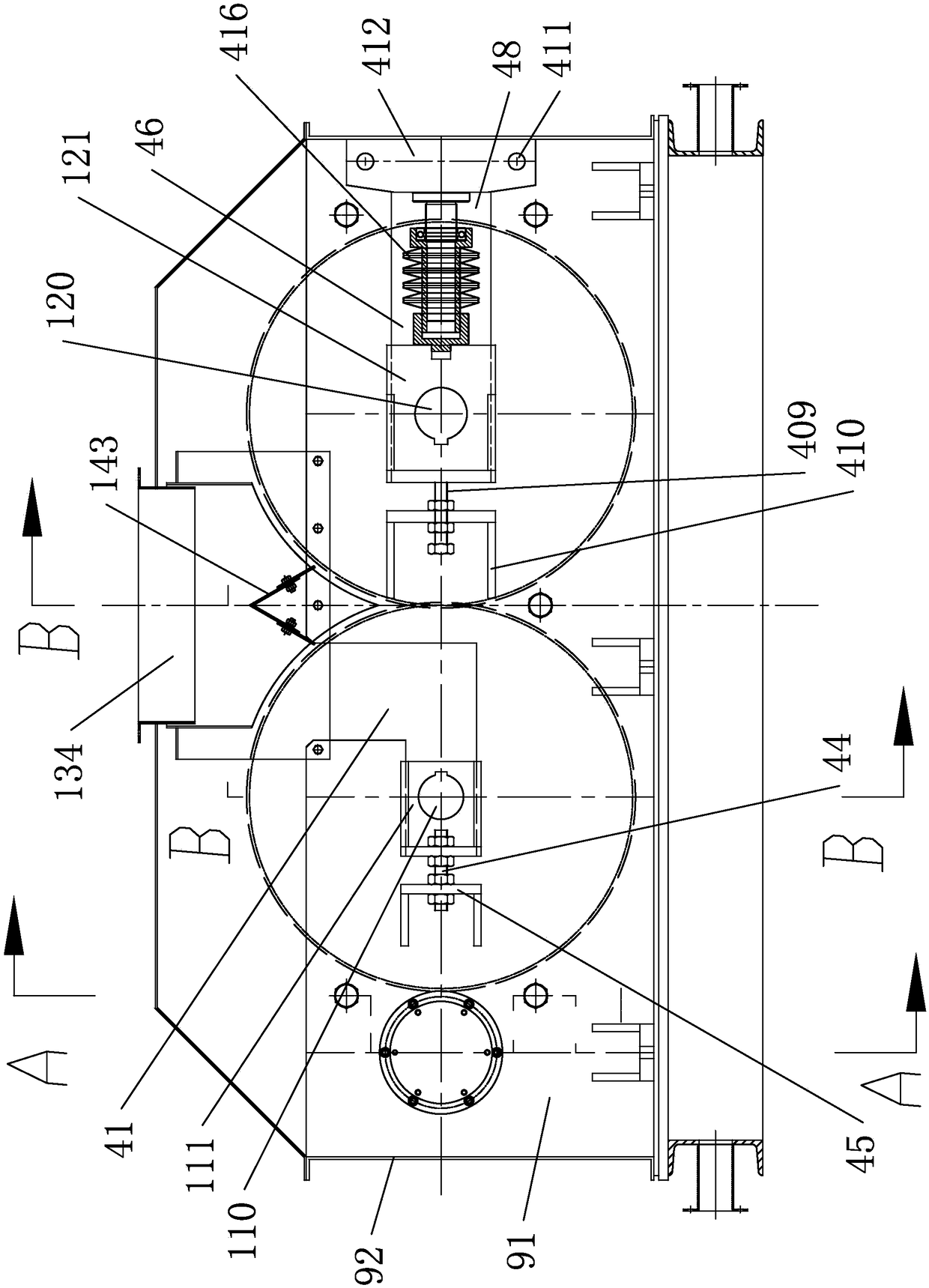

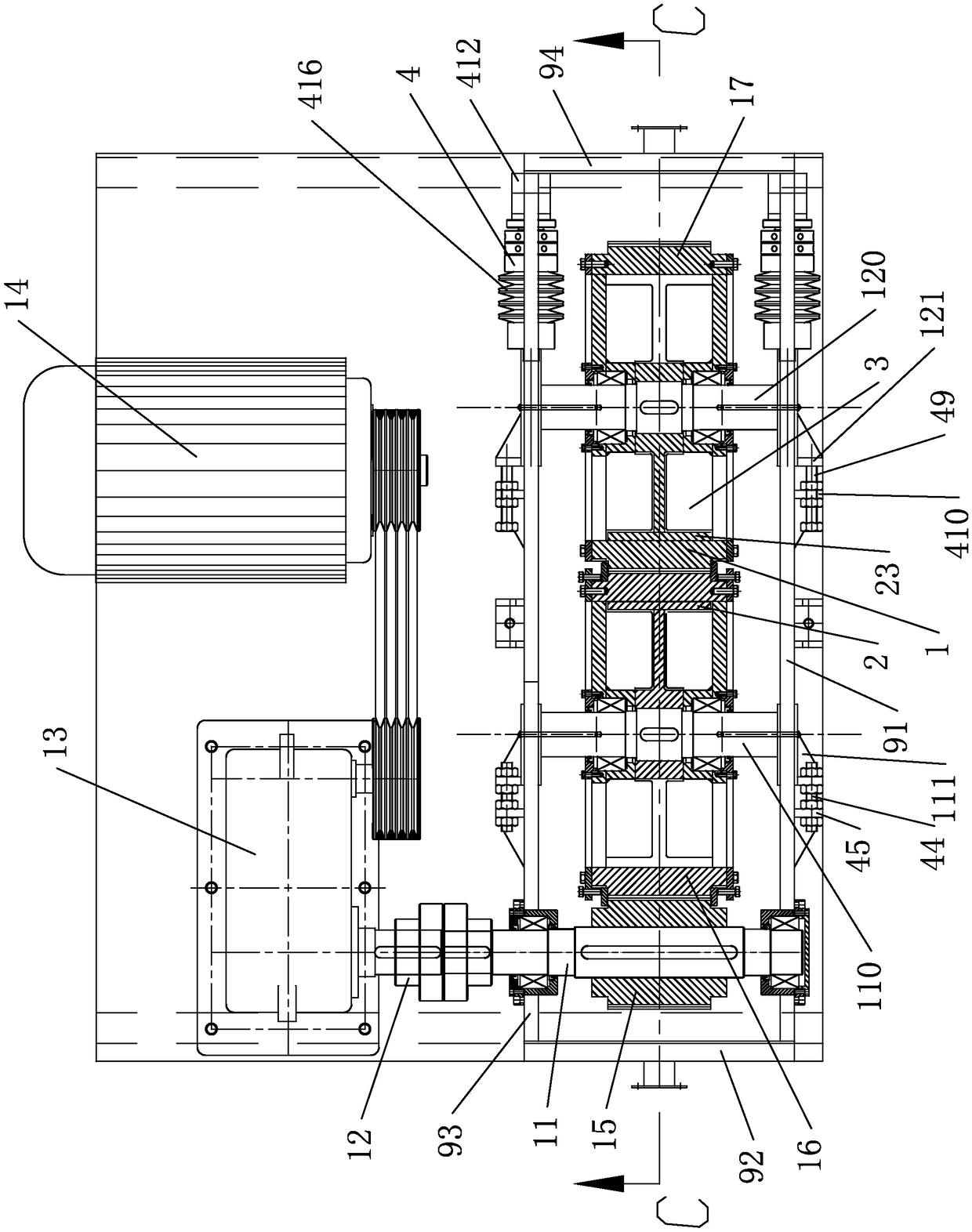

[0056] see Figure 2-6 The gear ring die granulator shown includes a machine base 9, a granulation device 1, a horizontal cutter device 2 or a directional cutter device 5, a discharge device 3, a translation device 4, and the like.

[0057] The base 9 mainly includes a cuboid working space surrounded by a front plate 91, a rear plate 93, a left plate 92, and a right plate 94, a base 95 and the like.

[0058] 1. Granulating device

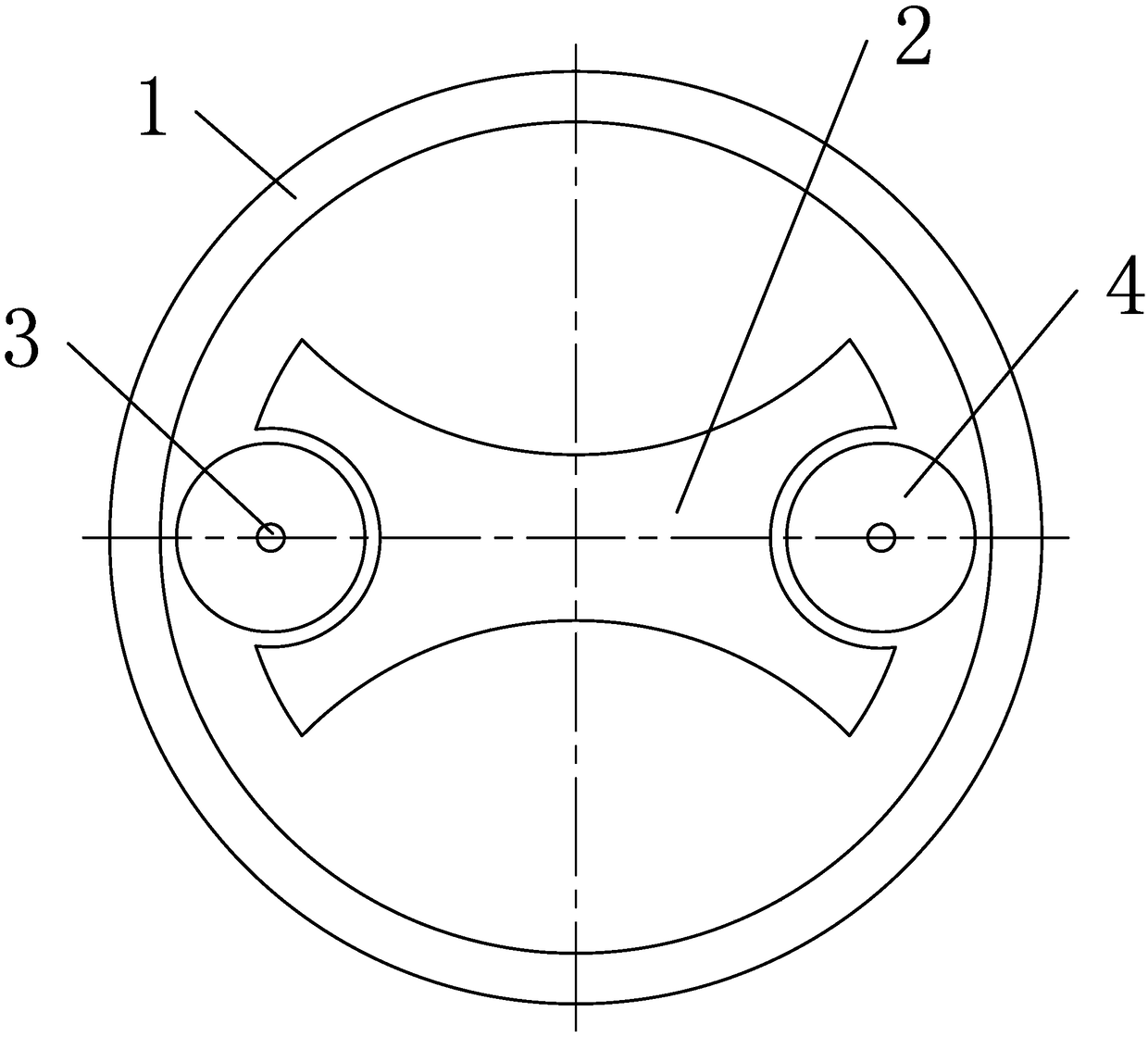

[0059] see Figure 7-10 , The granulating device 1 is mainly composed of the main gear shaft 11, the main gear ring die 16, the pinion ring die 17, the hub 19, 119, the spokes 18, 118 and so on.

[0060] The main gear shaft 11 is rotatably arranged on the front plate 91 and the rear plate 93 through bearings. The main gear shaft 11 is connected with the output shaft of the speed reducer 13 through a shaft coupling 12, and the speed reducer and the motor 14 are driven by a belt.

[0061] There are two gear ring dies, namely main gear ring die 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com