Powder high-temperature alloy horizontal extrusion integrated sheath and manufacturing method thereof

A high-temperature alloy and sheathing technology, which is applied to the supporting components of blades, engine components, machines/engines, etc., can solve the problems of wasting powder superalloy materials, increasing extrusion resistance, and cracking of extruded rods, and achieves reduction Small waste, reduced extrusion resistance, enhanced welding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

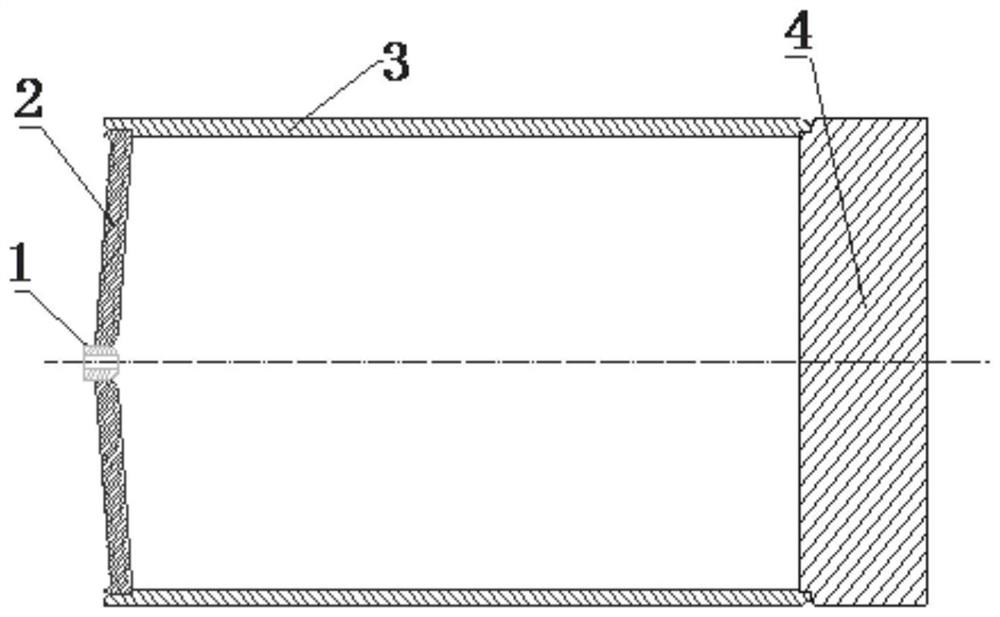

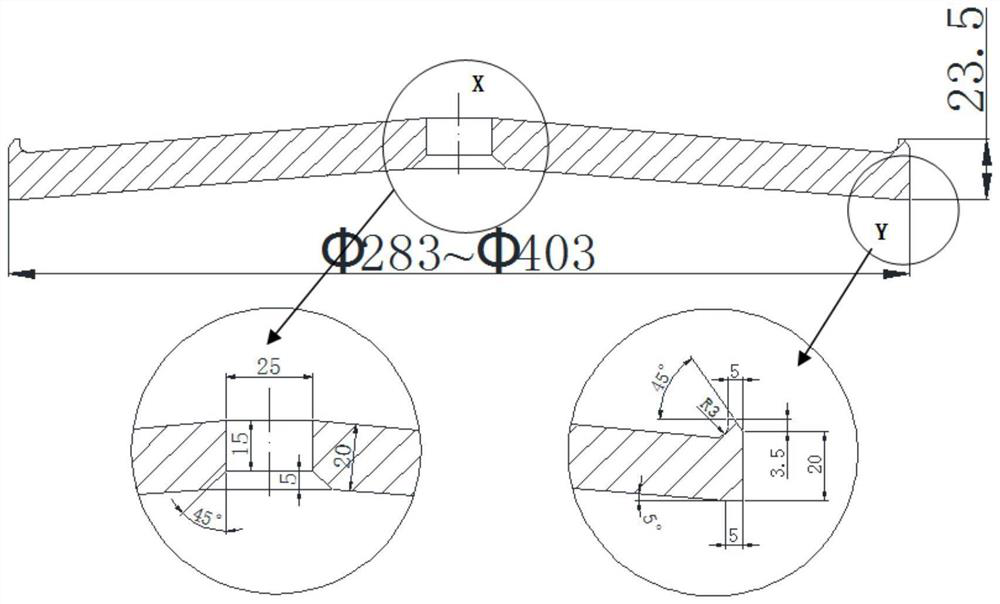

[0043] (1) Process the parts of the integrated sheath according to the drawings, wherein the diameter of the upper cover of the sheath is Φ343mm, the outer diameter of the outer wall of the sheath is Φ360mm, the inner diameter of the outer wall of the sheath is Φ333mm, the height of the outer wall of the sheath is 730mm, the diameter of the tail pad of the sheath is Φ360mm, and the outer diameter of the sheath is Φ360mm. Tail pad height 100mm;

[0044] (2) Clean each part of the processed bag with gasoline first, and then use acetone to clean until there are no obvious impurities visible to the naked eye in the acetone;

[0045] (3) Argon arc welding is used to weld the parts of the integrated sheath;

[0046] (4) Vacuum annealing is carried out on the sheath after welding at 600°C, and the annealing time is 16h;

[0047] (5) After annealing, in order to ensure the tightness of the bag, a leak detector is used to test the tightness of the bag. The leak rate should be 3×10 in ...

Embodiment 2

[0050] (1) Process the parts of the integrated sheath according to the drawings, wherein the diameter of the upper cover of the sheath is Φ403mm, the outer diameter of the outer wall of the sheath is Φ420mm, the inner diameter of the outer wall of the sheath is Φ393mm, the height of the outer wall of the sheath is 620mm, the diameter of the tail pad of the sheath is Φ420mm, and the outer diameter of the sheath is Φ420mm. Tail pad height 150mm;

[0051] (2) Clean each part of the processed bag with gasoline first, and then use acetone to clean until there are no obvious impurities visible to the naked eye in the acetone;

[0052] (3) Argon arc welding is used to weld the parts of the integrated sheath;

[0053] (4) Vacuum annealing is carried out on the sheath after welding at 600°C, and the annealing time is 16h;

[0054] (5) After annealing, in order to ensure the tightness of the bag, a leak detector is used to test the airtightness of the bag. The leak rate should be 5×10 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com