Die assembly tool for extrusion molding

A technology of extrusion forming and die assembly, which is used in metal extrusion forming tools, metal extrusion dies, manufacturing tools, etc., can solve the problems of worrying about the strength of the bridge portion, interference, and hinder the smooth introduction of metal materials, so as to improve the The effect of improving pressure resistance and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

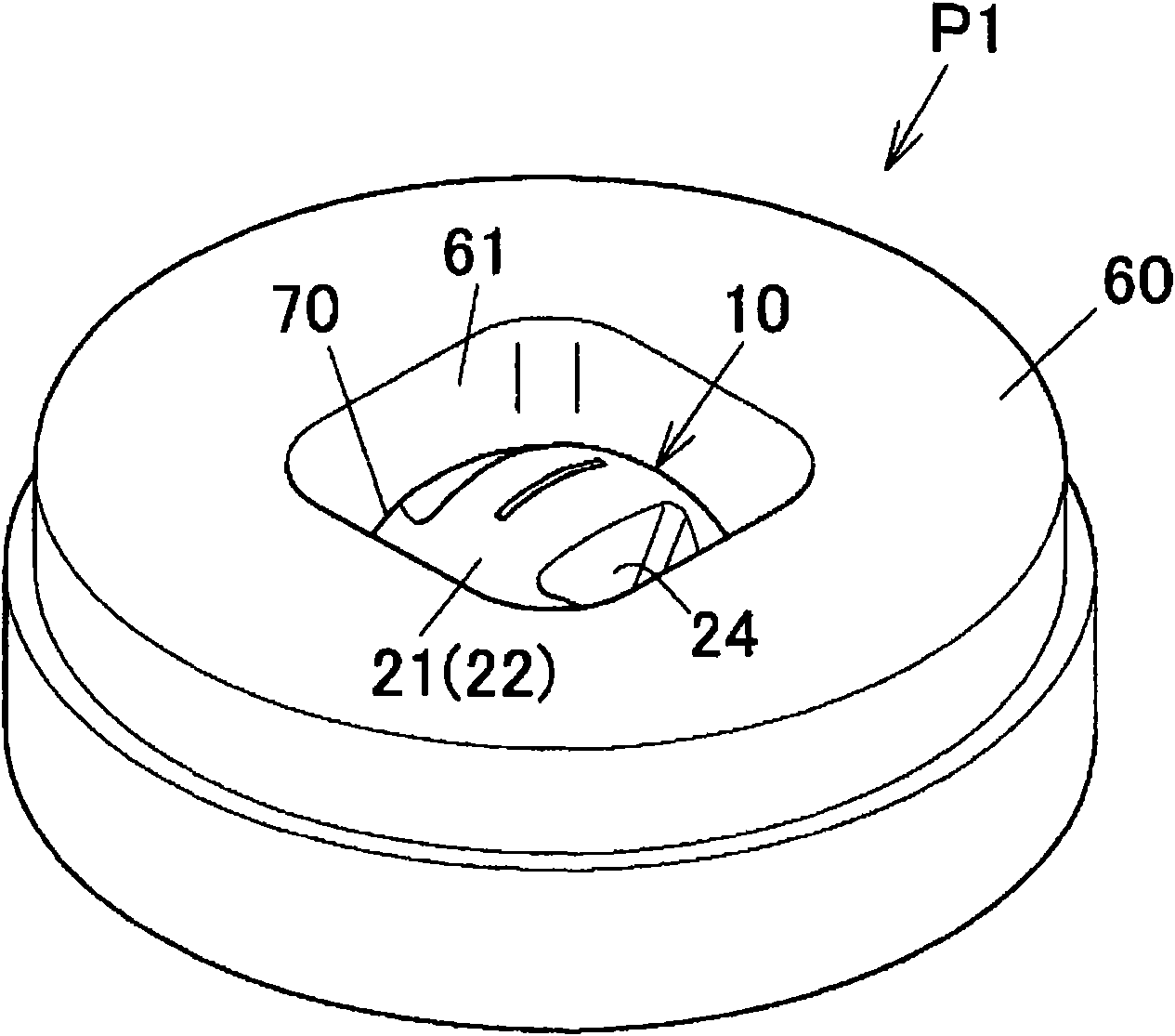

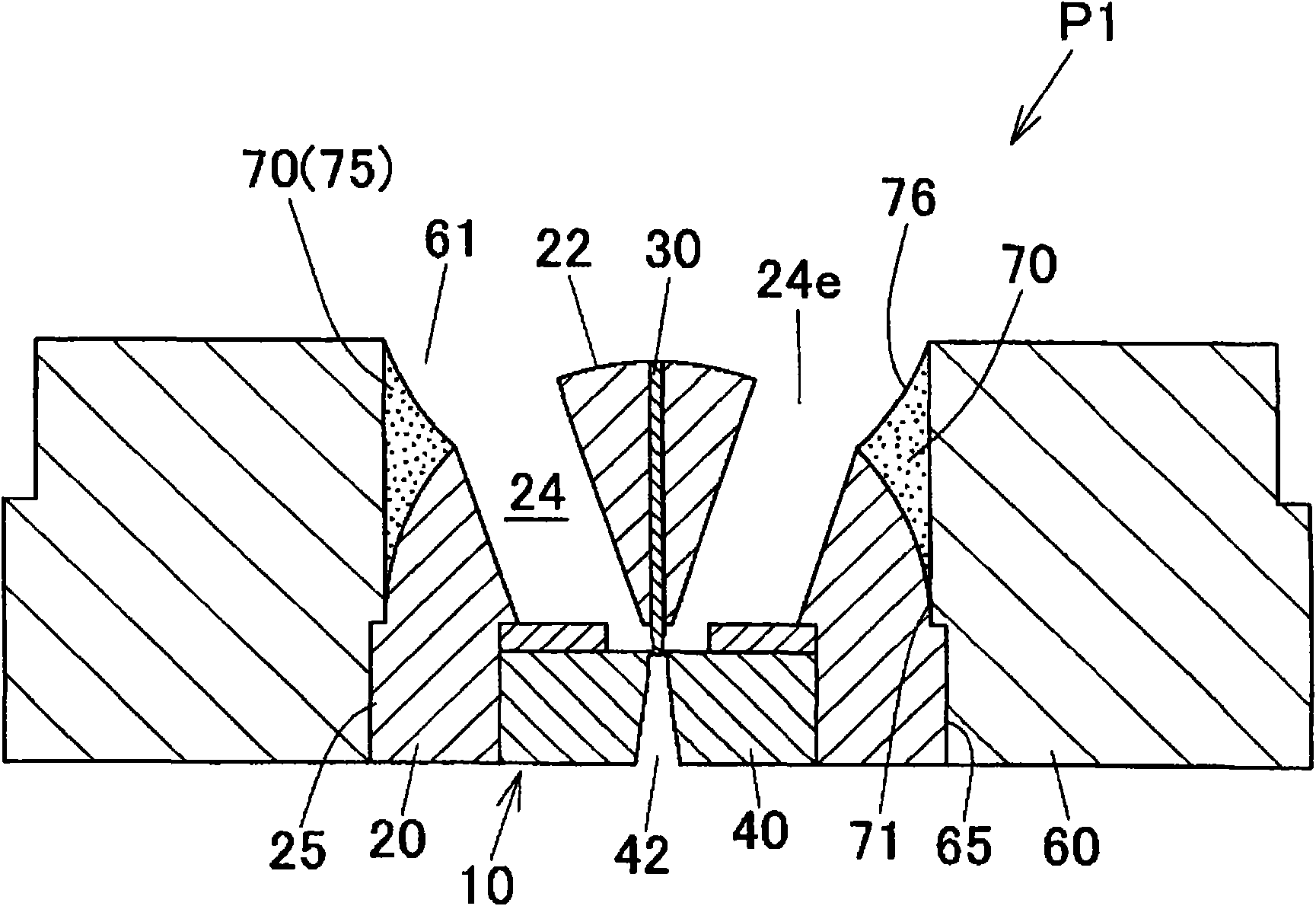

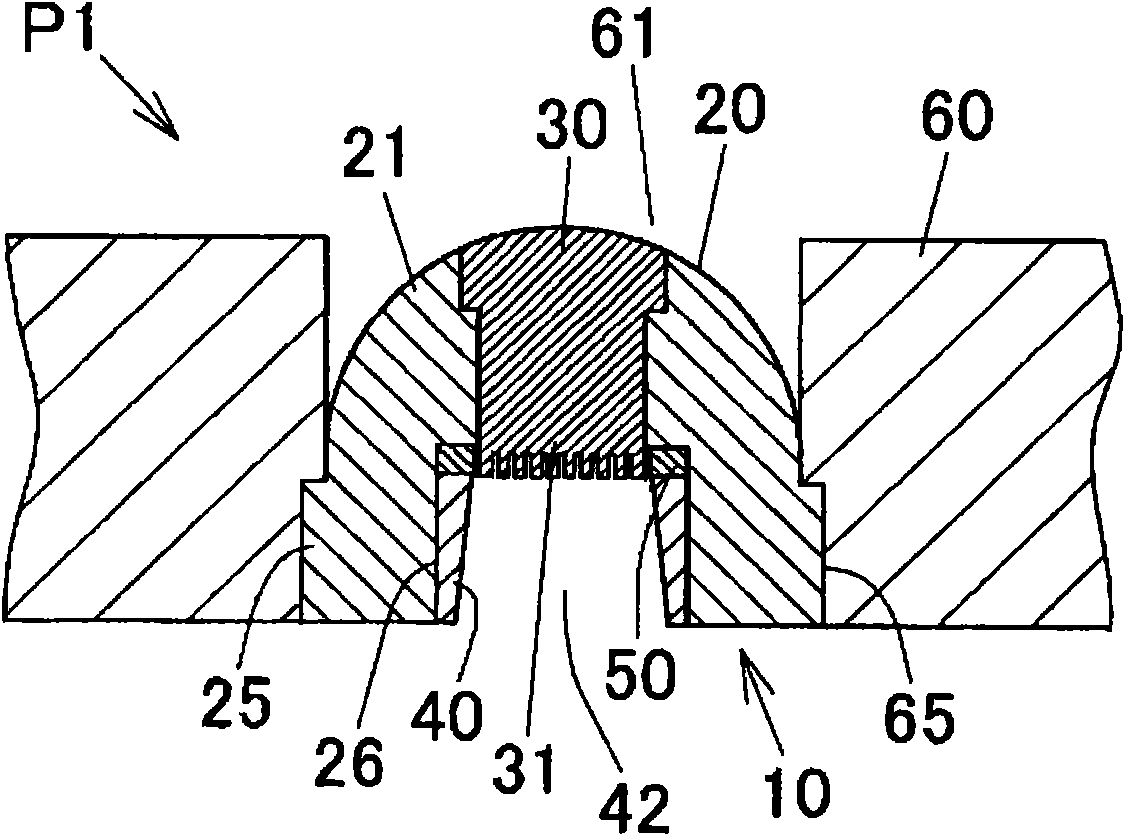

[0171] Prepare and above-mentioned embodiment (refer to Figures 1 to 4 ) corresponding to the mold assembly tool (P1). In the mold (10) of the mold assembly tool (P1), two orifices (24) of the pressure receiving part (21) are formed correspondingly on both sides of the extrusion hole (11) in the thickness direction. The inclination angle (θ) of the orifice (24) was adjusted to 20°. The blank pressure-receiving surface (22) is formed as a convex spherical surface of a 1 / 2 sphere with a radius of 30mm.

[0172] In addition, the inlet side peripheral portion of the mold installation hole (61) of the mold installation plate (60) is not specially cut off, and the inner peripheral surface of the mold installation hole (61) constitutes the peripheral wall surface of the aluminum storage portion (70) as it is. , the peripheral wall surface of the aluminum storage part (70) is arranged parallel to the axis (A1) of the mold (10).

[0173] In addition, the male mold (30) is adjusted ...

Embodiment 2

[0180] Prepare the same as the above-mentioned first modified example (refer to Figure 14 ) corresponding to the mold assembly tool (P2). In this mold assembly tool (P2), the inlet side peripheral portion of the mold installation hole (61) of the mold installation plate (60) is cut into a chamfered shape, and a cutout portion is formed on the upstream side outer periphery of the aluminum storage portion (70). (72). The inner peripheral wall surface (73) of the cutout portion (72) is formed as a tapered surface whose diameter gradually decreases toward the downstream side.

[0181] In addition, extrusion molding was performed similarly to the above, and the same evaluation was performed. The results are shown in Table 1.

Embodiment 3

[0183] Prepare the same as the above-mentioned second modified example (refer to Figure 15 ) corresponding to the mold assembly tool (P3). In this mold assembly tool (P3), the inlet side peripheral portion of the mold installation hole (61) of the mold installation plate (60) is cut into a step shape (L shape), and the upstream side outer periphery of the aluminum storage part (70) A cutout (72) is formed. The inner peripheral wall surface (73) of the cutout portion (72) is arranged parallel to the axis (A1) of the mold (10).

[0184] In addition, extrusion molding was performed similarly to the above, and the same evaluation was performed. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com