A production process of ultra-high-strength 7055 aluminum alloy profiles

An aluminum alloy profile and production process technology, applied in the field of aluminum alloy hot extrusion, can solve the problems of prone to cracks and low extrusion efficiency of 7055 aluminum alloy profiles, reduce extrusion resistance, optimize extrusion process parameters, reduce The effect of small mold deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A production process of ultra-high-strength 7055 aluminum alloy profiles, comprising the following steps:

[0027] A. Melting and casting: prepare aluminum alloy raw materials according to the weight ratio of 7055 aluminum alloy, add the prepared aluminum alloy raw materials into the melting furnace and mix them evenly, then melt them into liquid aluminum alloys, cool and cast the liquid aluminum alloys into aluminum alloy casting rods;

[0028] B. Homogenization treatment: heat the aluminum alloy cast rod to 475°C, keep it warm for 12 hours, and cool to normal temperature to obtain a homogeneous aluminum alloy cast rod;

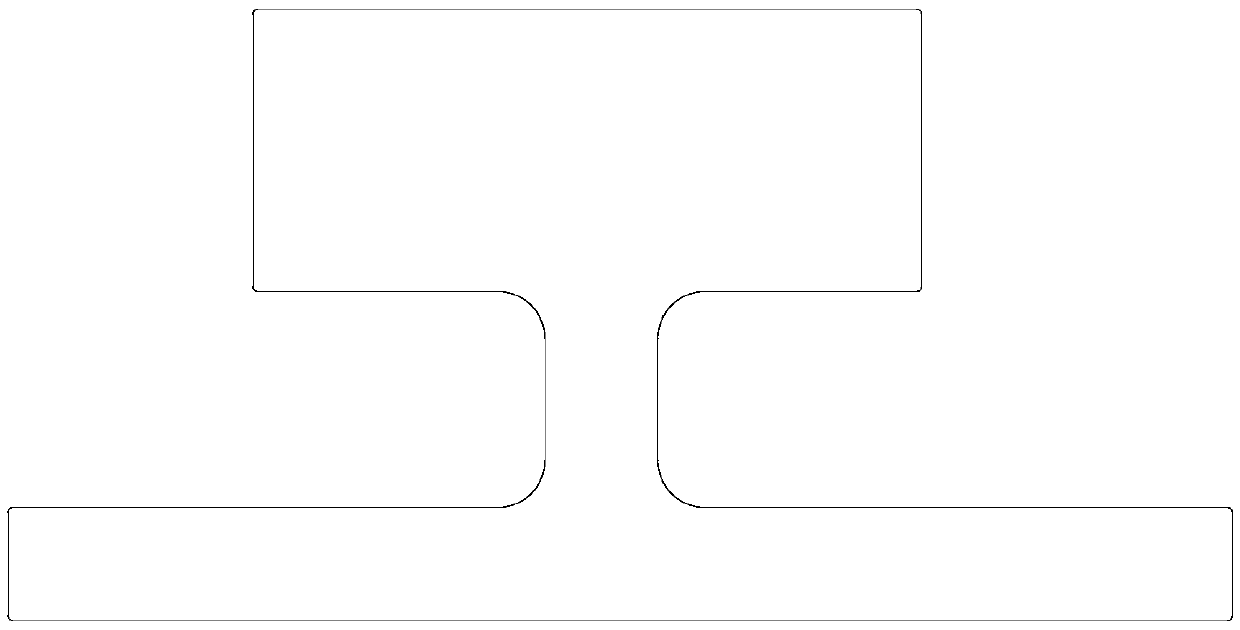

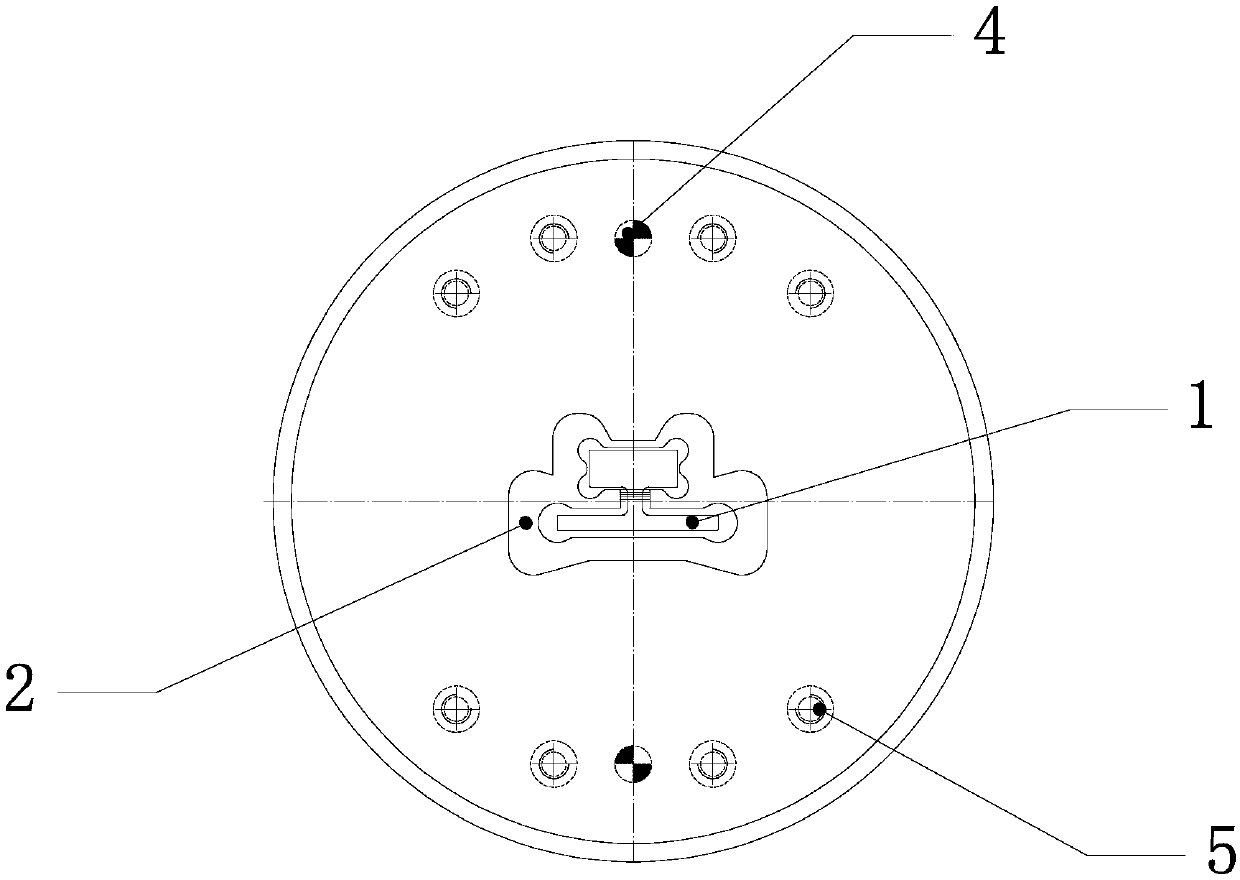

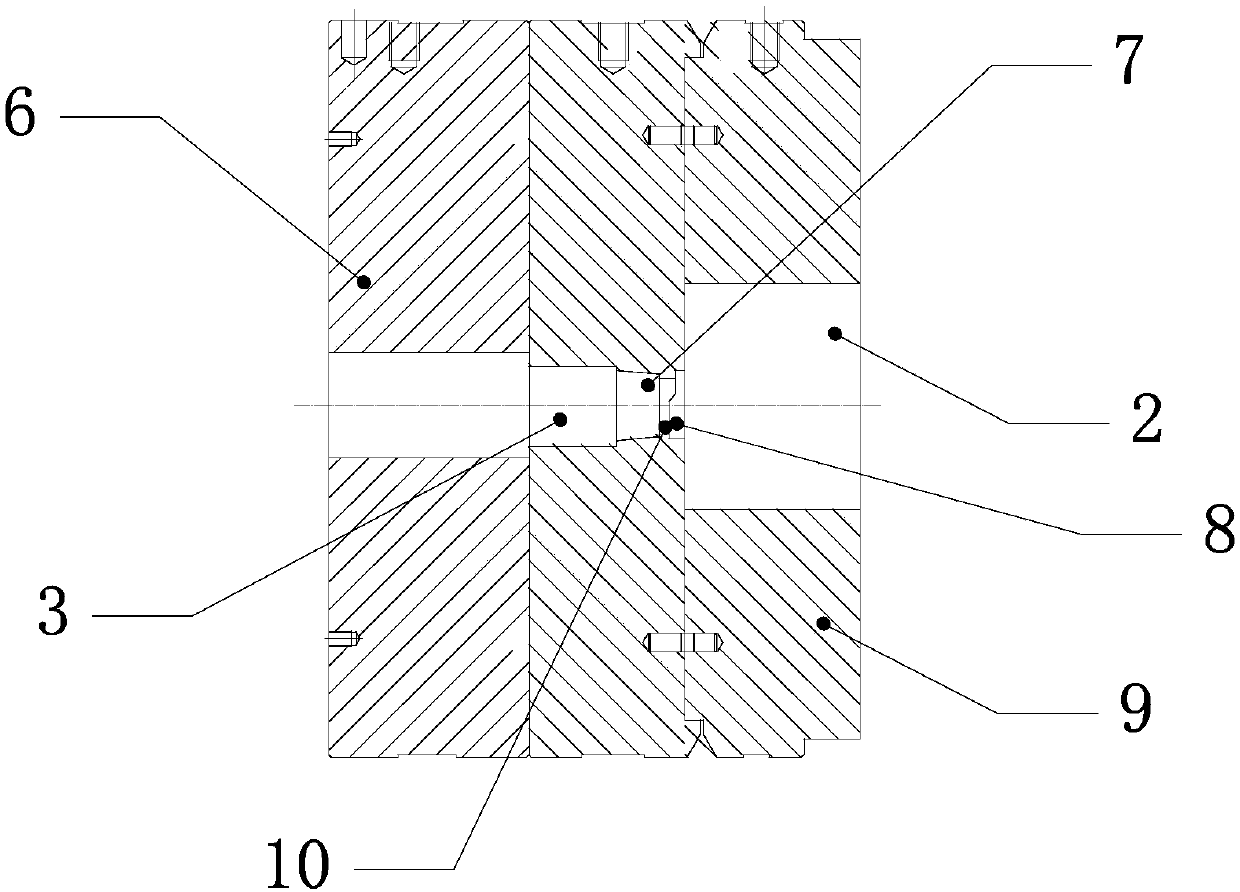

[0029] C. Extrusion: Send the homogenized aluminum alloy cast rod into the extruder for extrusion, so that the aluminum alloy cast rod can pass through the extruder smoothly and then enter the mold, and then extruded in the mold to obtain 7055 aluminum For alloy profiles, the heating temperature of the mold is 440°C, the heating time is 5 hours, the h...

Embodiment 2

[0032] The difference between Example 2 and Example 1 is that in step B, the aluminum alloy cast rod is heated to 485° C., kept for 10 hours, and cooled to room temperature to obtain a homogeneous aluminum alloy cast rod.

Embodiment 3

[0034] The difference between Example 3 and Example 1 is that the heating temperature of the mold in step C is 460°C, the heating time is 5 hours, the heating temperature of the extrusion cylinder is 420°C, the heating temperature of the aluminum alloy cast rod is 400°C, and the aluminum alloy casting rod is 400°C. The extrusion speed of the alloy cast rod is 0.8m / min, the diversion port of the mold is a butterfly structure, the corner of the butterfly structure at the diversion port of the mold is arc-shaped, the length of the working belt in the mold is 25mm, and the working belt is set There is a cooling device, the cooling device includes a liquid nitrogen system and a temperature control system, and the extrusion breakthrough pressure of the mold is 19bar.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com