Manufacturing method of thin-walled large-scale honeycomb ceramic carrier mold that can be repeatedly coated

A technology of a honeycomb ceramic carrier and a manufacturing method, which is applied in the field of manufacturing a thin-walled large-scale honeycomb ceramic carrier, can solve the problems of increased extrusion resistance, poor drill bit rigidity, and low drilling efficiency, so as to reduce extrusion resistance and the cost of the mold The effect of high pressure, elimination of positioning deviation, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

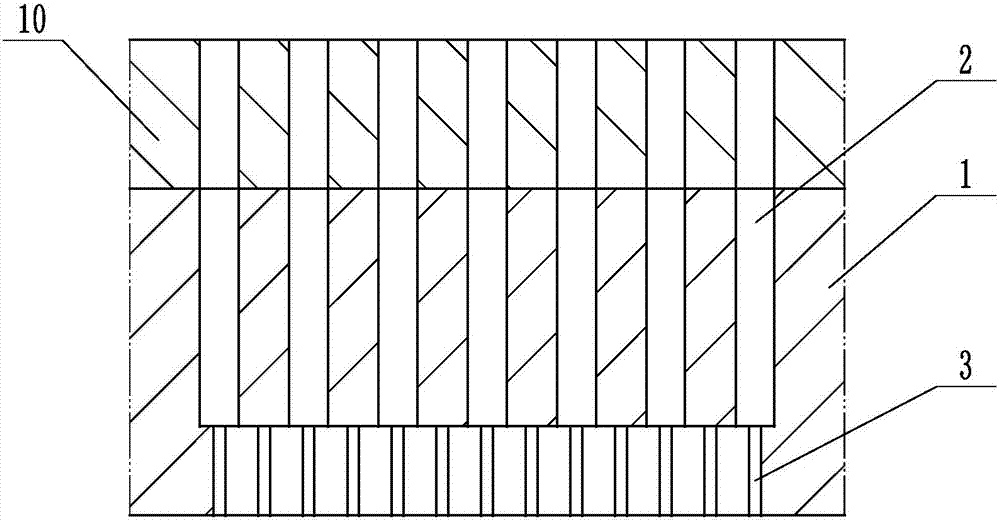

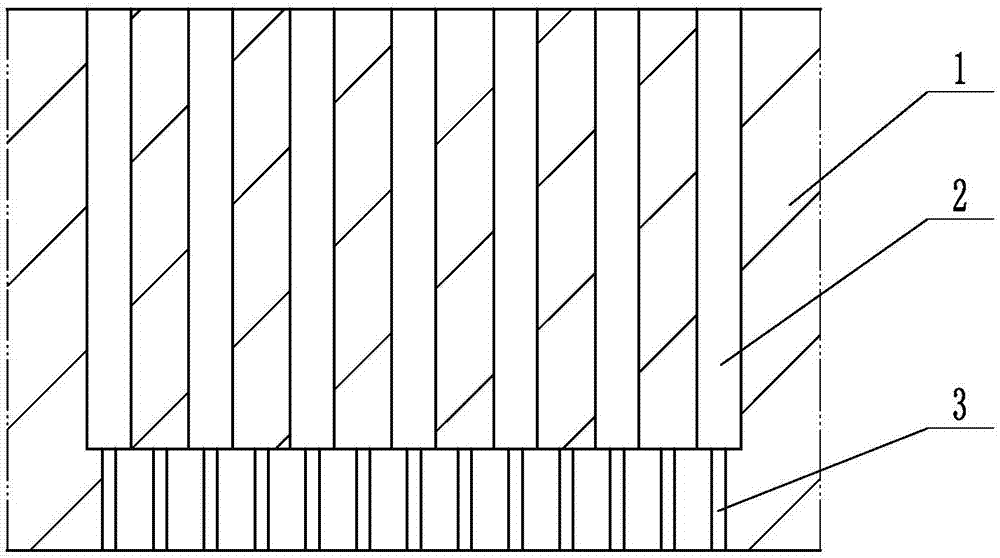

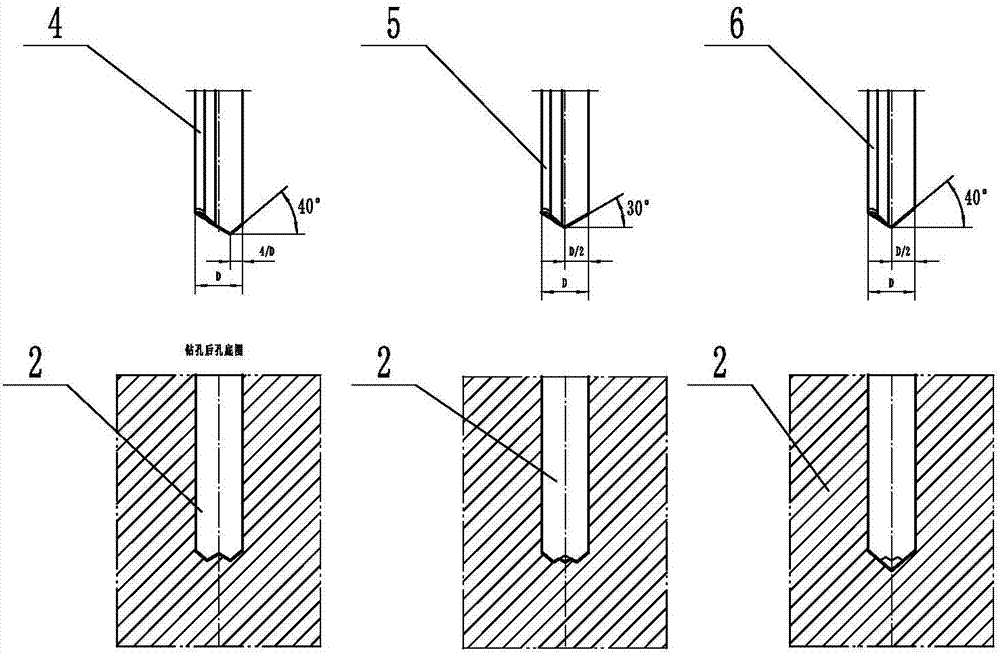

[0032] Such as figure 2 As shown, the method for manufacturing a thin-walled large-size honeycomb ceramic carrier mold that can be coated repeatedly in this embodiment. The carrier mold includes a master mold 1. The master mold 1 is provided with a plurality of feeding holes 2 and corresponding to the feeding holes 2. Corresponding discharging trough 3; the carrier mold of the present invention can be used to produce thin-walled large-size honeycomb ceramic carriers with a hole density of 100-600 mesh, a wall thickness of 0.10-0.40mm, and a diameter of 190-330, and can withstand the pressure of 15MPA-30MPA .

[0033] The manufacturing method of the carrier mold includes the following steps:

[0034] Step 1: Use mold steel or other alloy steel to make template blanks;

[0035] The second step: compile the feed hole drilling processing program, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com