Polymer alloy products containing intercrystalline bridge texture and processing method thereof

A polymer and alloy technology, which is applied in the field of polymer alloy products with high mechanical properties and its processing, can solve the problems of cumbersome preparation and feeding, and achieve the effects of mild process conditions, small extrusion resistance, and convenient changes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] 1. Polymer raw materials: The polymer combination is high-density polyethylene / isotactic polypropylene (HDPE / iPP), HDPE is 5000S produced by Beijing Yanshan Petrochemical Co., Ltd., the melt flow index is 0.946g / 10min, and iPP is T30S produced by PetroChina Dushanzi Petrochemical Company has a melt flow index of 2.9g / 10min;

[0046] 2. Melt blending and billet extrusion molding: mix HDPE and iPP pellets at a weight ratio of 5:95, and then heat them in a twin-screw extruder. Heating in five stages, temperature: 150°C, 170°C, 190°C, 200°C, 200°C, screw speed: 120 rpm, melted, plasticized and blended evenly, extruded into a cylindrical rod with an inner diameter of 45 mm In the die, it is shaped and cooled to become a solid HDPE / iPP polymer alloy rod blank with a diameter of 45 mm;

[0047] 3. Preheating of the billet: put the extruded HDPE / iPP alloy billet into the barrel (45 mm inner diameter) of the plunger extruder for heating, and set the temperature between HDPE and...

Embodiment 2

[0051] The mechanical properties of the HDPE / iPP (5 / 95) alloy sheet formed in Example 2 are listed in Table 2.

[0052] Table 2. Longitudinal and transverse strength of HDPE / iPP(5 / 95) alloy sheet

[0053] extrusion temperature

[0054] extrusion temperature

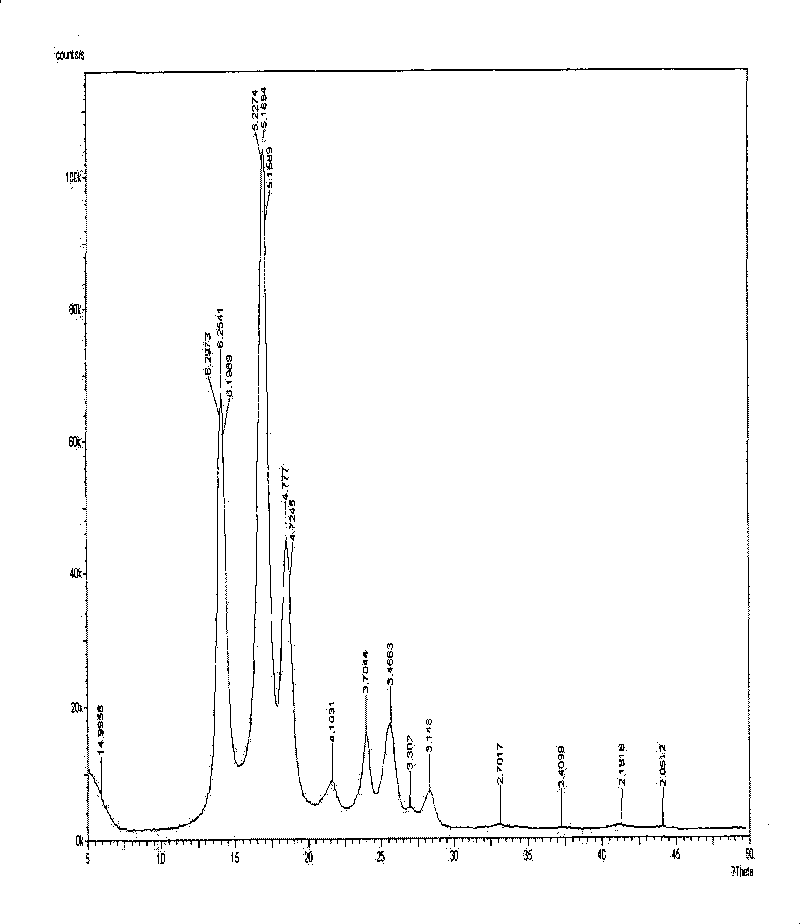

[0055] The wide-angle x-ray diffraction (WAXD) pattern of high-strength HDPE / iPP (5 / 95) alloy sheet is shown in figure 1 .

[0056] Example 2

[0057] 1. Polymer raw materials: The polymer combination is high-density polyethylene / isotactic polypropylene (HDPE / iPP), HDPE is 5000S produced by Beijing Yanshan Petrochemical Co., Ltd., the melt flow index is 0.946g / 10min, and iPP is T30S produced by PetroChina Dushanzi Petrochemical Company has a melt flow index of 2.9g / 10min.

[0058] 2. Melt blending: mix HDPE and iPP pellets according to the weight ratio of 10:90, and then put them into a single-screw extruder for heating. The extruder is heated in four stages from the feeding port to the machine head...

Embodiment 3

[0070] 1. Polymer raw material: The polymer combination is metallocene linear low density polyethylene / isotactic polypropylene (m-LLDPE / iPP), m-LLDPE is SP1520 produced by Mitsui Chemicals, Japan, and the melt flow index is 2.0g / 10min, iPP is T30S produced by China Petroleum Dushanzi Petrochemical Company, with a melt flow index of 2.9g / 10min;

[0071] 2. Melt blending and billet extrusion molding: Mix the pellets of m-LLDPE and iIPP according to the weight ratio of 10:90, and then put them into a twin-screw extruder for heating. The machine head is heated in five stages, the temperature is: 150°C, 170°C, 190°C, 200°C, 200°C, the screw speed is 120 rpm, melted, plasticized and blended evenly, then extruded into a cylindrical rod with an inner diameter of 45 mm In the material die, it is shaped and cooled to become a solid m-LLDPE / iPP polymer alloy rod blank with a diameter of 45 mm;

[0072] 3. Preheating of the billet: put the extruded m-LLDPE / iPP alloy billet into the barr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com