Integral weaving method for 2.5D seamless joint flat fabric

A technology of integral weaving and seamless butt joint, applied in the direction of woven fabrics, textiles and paper making, etc., can solve the problems of reducing the strength of the preform, destroying the integrity of the yarn, affecting the structural continuity of the preform, reducing internal defects, facilitating the Overall weaving, small thermal deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it should not be understood that the scope of the above-mentioned theme of the present invention is limited to the above-mentioned embodiments.

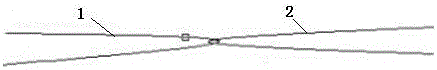

[0020] Such as figure 1 As shown, a mixed yarn bundle is formed by connecting a carbon fiber bundle 1 and a quartz fiber bundle 2 in series, and is used as a single yarn bundle after being connected. A 2.5D seamless butt joint flat fabric overall weaving method, in the weaving process, the warp direction yarns in the 2.5D flat weaving area are segmented to select different special fibers for series connection, so that different yarns are connected in pairs to form long yarn bundles, and used at the same time The formed mixed yarns are used as warp yarns for fabric weaving, and the required special fiber yarns are selected as weft yarns for overall weaving and molding. Using this method of weaving is conducive to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com