A method for preparing polyimide fibers based on imidization of o-methyl aramid

A technology of o-methyl aramidimide and polyimide fibers, which is applied in the field of high-performance fiber preparation, can solve problems such as weak strength, achieve dense fiber structure, high strength modulus, and overcome spinning processing difficulties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

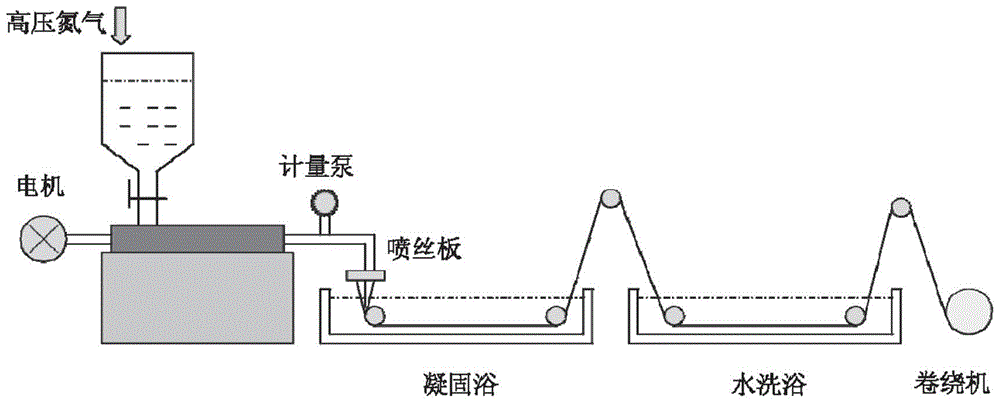

Method used

Image

Examples

Embodiment 1

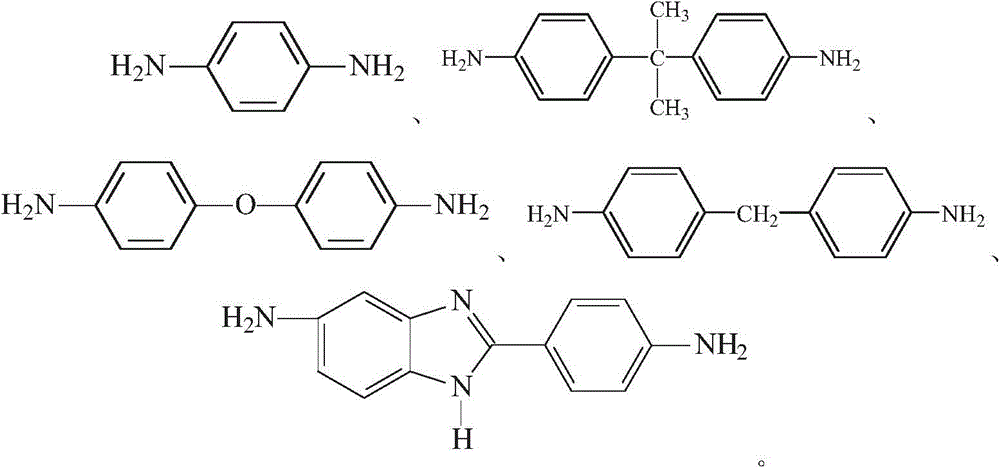

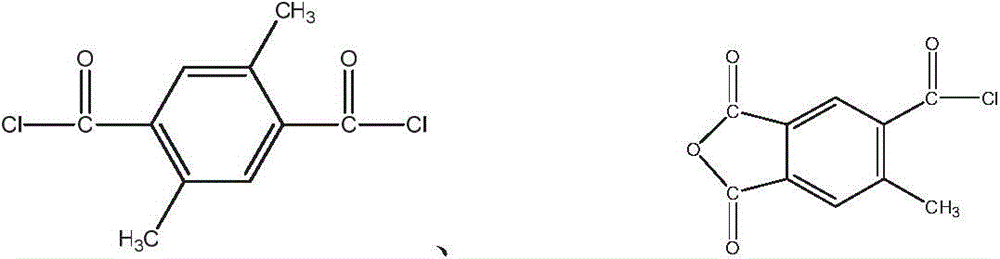

[0032] (1) In a three-necked flask with nitrogen, add 150ml NMP, add 10% CaCl 2 , stirred for 2 hours, added 10% diamine monomer, stirred at 10°C for 1.5 hours, then added an equimolar mass of o-methyl aromatic dichloride, stirred for 3 hours, added 0.5% dibenzoyl peroxide, as the reaction proceeded, The polymer is gradually precipitated, then washed and dried with water, and then dissolved and mixed with concentrated sulfuric acid to obtain anisotropic solute liquid crystal polyamide spinning solution.

[0033] (2) After degassing the above-mentioned liquid crystal polyamide spinning liquid, it is transported to the spinning assembly through a metering pump, and is spun by a dry-wet method. The height of the air layer is 1cm, the number of spinneret holes is 50, the diameter of the spinneret holes is 0.02mm, and the spinneret speed is 2m / min. , the temperature of the coagulation bath is 20°C. The obtained fiber enters into a water bath at 20°C, the winding speed is 80-90m / m...

Embodiment 2

[0037] (1) In a three-necked flask with nitrogen gas, add 150ml NMP, add 20% CaCl 2 , stirred for 3h, added 20% diamine monomer, stirred at 20°C for 1.5h, then added equimolar mass o-methylaromatic dichloride, added 1% isoquinoline, stirred for 4h, as the reaction proceeded, the polymer gradually Precipitate, then wash and dry with water, and then dissolve and prepare slurry with concentrated sulfuric acid to obtain anisotropic solute-type liquid crystal polyamide spinning solution.

[0038] (2) After degassing the above-mentioned liquid crystal polyamide spinning liquid, it is transported to the spinning assembly through a metering pump, and is spun by a dry-wet method. The height of the air layer is 2cm, the number of spinneret holes is 300, the diameter of the spinneret holes is 1.0mm, and the spinneret speed is 50m / min. , the temperature of the coagulation bath was 30°C. The obtained fiber enters into a water bath at 30°C, the winding speed is 80-90m / min, and dried to ob...

Embodiment 3

[0042] (1) In a three-necked flask with nitrogen gas, add 150ml NMP, add 30% CaCl 2 , stirred for 4 hours, added 40% diamine monomer, stirred at 60°C for 1.5 hours, then added an equimolar mass of o-methyl aromatic dichloride, added 0.5% acetic anhydride, stirred for 5 hours, as the reaction progressed, the polymer gradually precipitated , then washed with water and dried, and then dissolved in concentrated sulfuric acid to prepare the slurry to obtain anisotropic solute-type liquid crystal polyamide spinning solution.

[0043] (2) After degassing the above-mentioned liquid crystal polyamide spinning liquid, it is transported to the spinning assembly through a metering pump, and is spun by a dry-wet method. Among them, the height of the air layer is 40cm, the number of spinneret holes is 100, the diameter of the spinneret holes is 0.04mm, and the spinneret speed is 20m / min. , the temperature of the coagulation bath is 60°C. The obtained fiber enters a 60°C water bath, the wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com