Refractory ceramic plunger machine

A technology of high-temperature-resistant ceramics and plunger machines, applied in the field of high-temperature structural ceramics, can solve problems such as unqualified quality of porcelain clay, danger, and rupture of the extrusion port.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

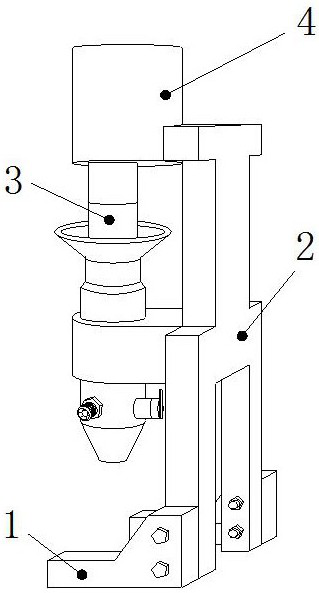

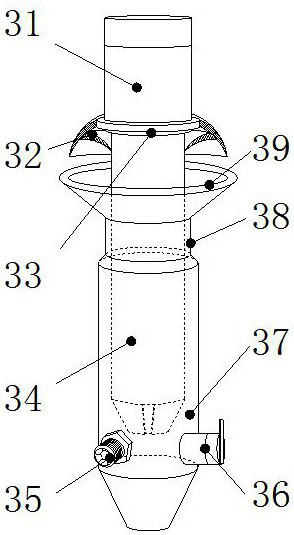

[0024] as attached figure 1 To attach Figure 5 Shown:

[0025] The present invention provides a high-temperature resistant ceramic plunger machine, the structure of which includes a support foot 1, a support frame 2, a plunger device 3, and a driver 4. It is embedded and connected to the left end of the middle part of the support frame 2, and the driver 4 is axially connected to the upper end of the plunger device 3. The plunger device 3 includes a plunger pump 31, an anti-overflow cap 32, a fixed ring 33, a plunger 34, an exhaust Port 35, pressure relief port 36, tapered barrel 37, connecting ring 38, bell mouth 39, the lower end of the plunger pump 31 is connected with the anti-overflow cap 32 through the fixing ring 33, the upper end of the plug column 34 is connected with the column The lower end of the plug pump 31 is embedded and connected, the exhaust port 35 is threadedly connected to the lower end of the conical barrel 37, the pressure relief port 36 is movably eng...

Embodiment 2

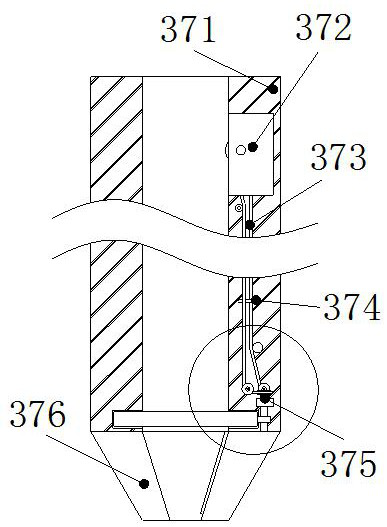

[0032] as attached Figure 6 to attach Figure 7 Shown:

[0033] Wherein, the rotating ring 75e includes a ring body e1, a contraction piece e2, and a scraping piece e3, the ring body e1 is embedded and connected with the inner side of the outer cover 371, and the shrinking piece e2 is embedded and connected with the right end of the ring body e1. The upper end of the scraping piece e3 is welded to the inside of the shrinking piece e2, and the scraping piece e3 is slidably connected to the left side of the shrinking piece e2, and is installed at an inclined angle. The angle is the same as that of the extrusion port 376, so that the scraping The sheet e3 can keep in contact with the surface of the inner wall of the extrusion port 376, which is beneficial to scrape off the porcelain mud adhered to the inner wall behind the plunger.

[0034] Wherein, the scraping piece e3 includes a support block r1, a connecting piece r2, a deflection shaft r3, and a vibrating column r4. Weld...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com