Large-size hollow ingot and ingot casting method

A hollow ingot, large-scale technology, applied in the field of aluminum alloys, can solve problems such as uneven composition, cracks, and eccentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

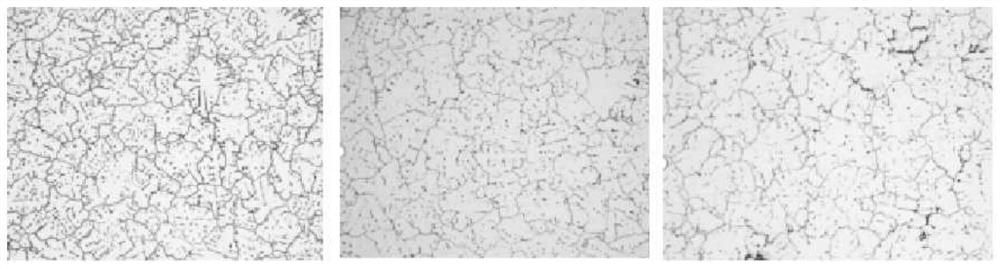

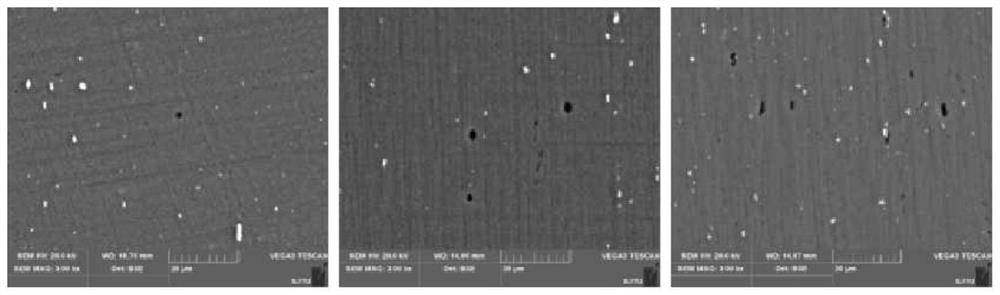

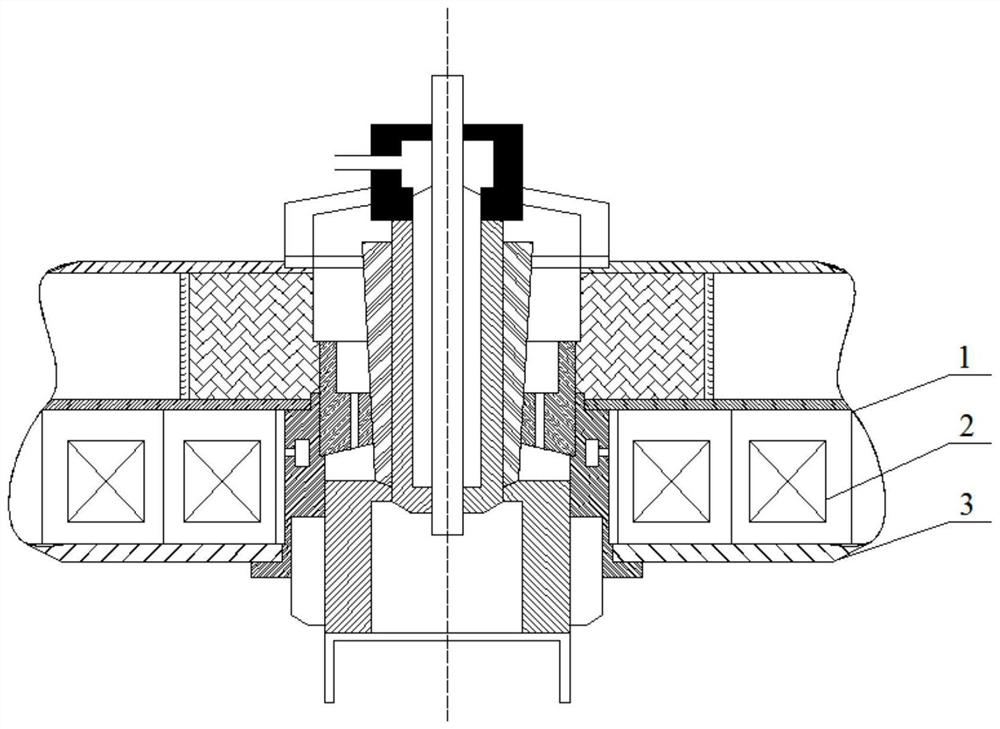

Image

Examples

Embodiment 1

[0041] A method for casting large-scale hollow ingots, including the steps of batching, smelting and purifying, casting and homogenizing, the specific steps are as follows:

[0042] (1) Ingredients

[0043] The formula of the large-scale hollow ingot based on the ingredients is: according to the weight percentage, Si≤0.2%, Fe≤0.3%, Cu≤0.1%, Mn0.5-1.2%, Mg6.0-6.5%, Cr≤0.1, Ni≤0.05, Zn≤0.1, Ti≤0.15, Be0.001-0.005%, Zr0.05-0.15%, Na≤10ppm, Ca≤10ppm, the balance is Al and unavoidable impurity elements; according to large-scale hollow casting The formula composition of the ingot is used for batching. The specific chemical composition is shown in Table 1. High-purity aluminum ingots, first-class scrap, aluminum-titanium master alloy, aluminum-manganese master alloy, aluminum-beryllium master alloy, aluminum-zirconium master alloy and magnesium metal were weighed as raw material;

[0044] (2) Smelting and purification

[0045] a. Feeding structure: Furnace loading sequence: 99.85%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com