Aluminum profile extrusion die for frame

A technology for extrusion dies and aluminum profiles, applied in the direction of metal extrusion dies, etc., can solve the problems that are difficult to remove and affect the appearance of profiles, and achieve the effects of good strength and rigidity, increased strength, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

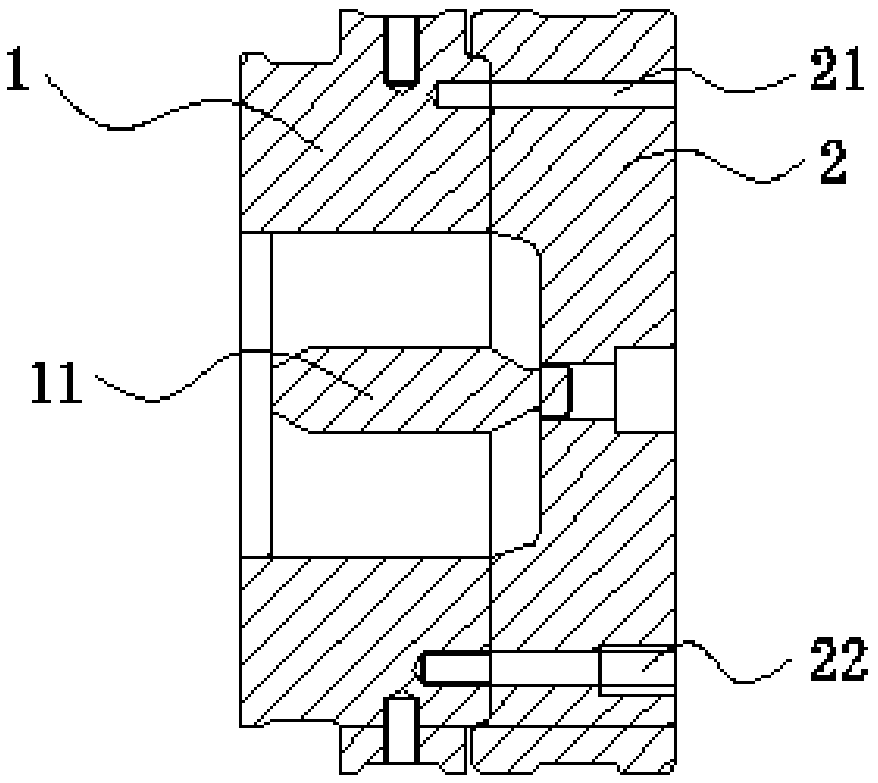

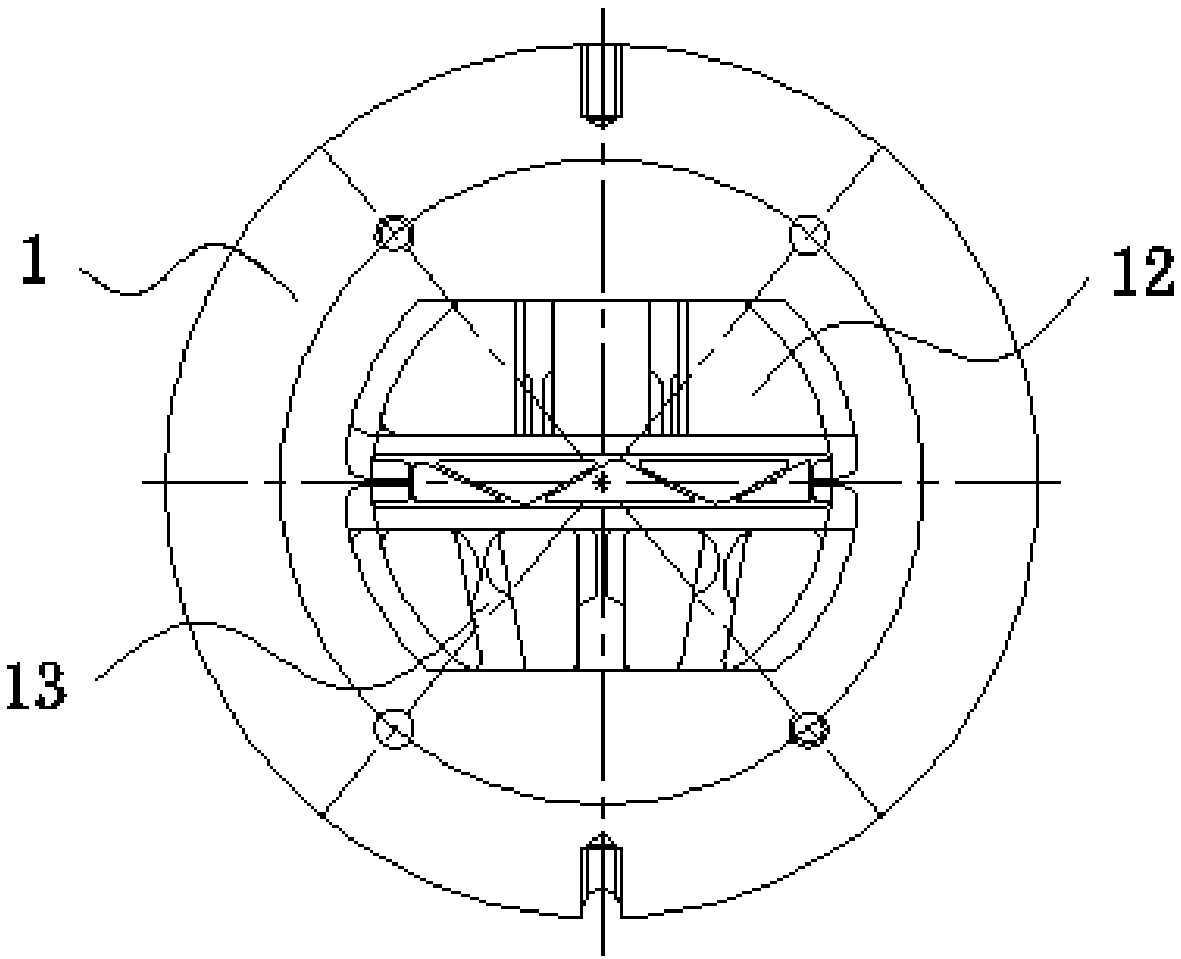

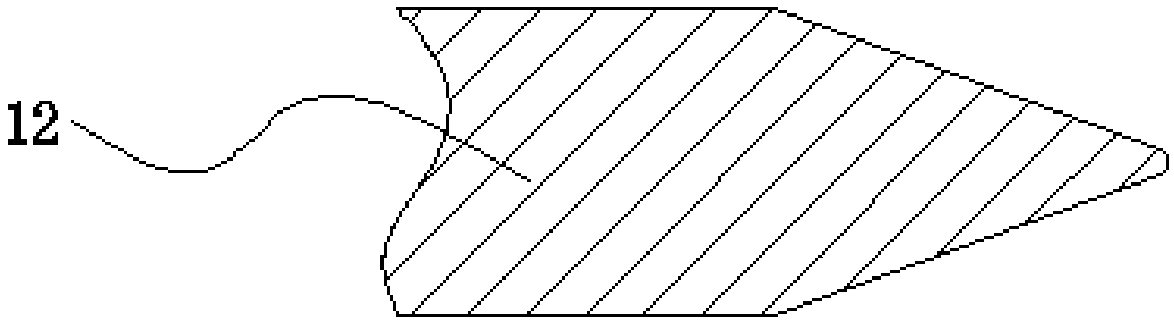

[0019] As shown in the figure: an aluminum profile extrusion die for a vehicle frame, an aluminum profile extrusion die for a vehicle frame, including an upper die 1 and a lower die 2, and a positioning pin is passed between the upper die 1 and the lower die 2 21 is connected with the fastening screw 22, and the middle part of the upper mold 1 is provided with a mold core 11, and there are seven diversion holes 12 around the mold core 11, and the arrangement of the diversion holes 12 is three on the upper side and four on the lower side, which are suitable for the structure of the aluminum profile. , a shunt bridge 13 is arranged between the shunt holes 12, the shunt bridge 13 is designed as a pointed shape with an inlet cross-section forming an included angle of 40 degrees, and the rounded corners of the pointed head are inverted R5, and the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com