Space guide vane body of a staggered centrifugal pump

A space guide vane and centrifugal pump technology, which is applied in the field of hydraulic machinery, can solve problems such as reducing the pressure pulsation at the outlet of the space guide vane, and achieve the effects of reducing dynamic and static interference effects, uniform pressure distribution, and reducing vibration and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

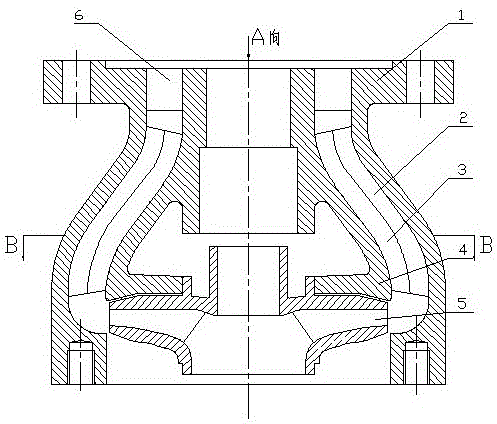

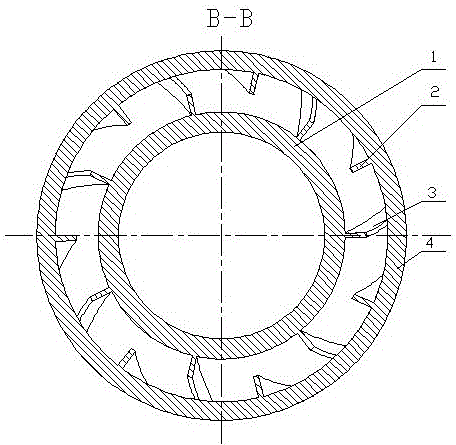

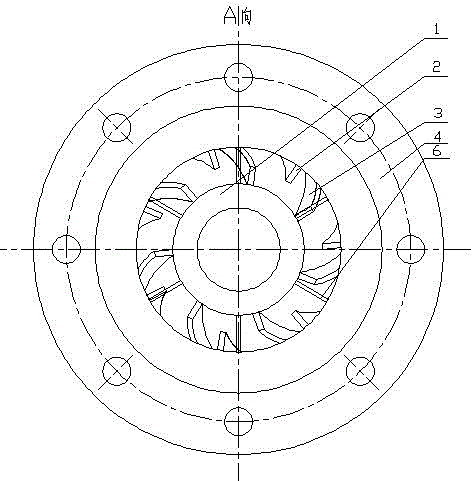

[0020] to combine figure 1 , 2 , 3. The space guide vane body of the staggered centrifugal pump according to the present invention includes upper guide vane 2, lower guide vane 3, fixed vane 6, hub body 4 and casing 1, the upper guide vane 2 and the lower guide vane body of the space guide vane body The guide vanes 3 are staggered and evenly distributed, the upper guide vanes 2 are fixed on the casing 1 , and the lower guide vanes 3 are fixed on the hub body 4 . The upper guide vane 2 is located near the middle of two adjacent lower guide vanes 3 in the circumferential direction. The upper guide vane 2 and the lower guide vane 3 are obtained by cutting the upper and lower parts of the guide vane blades designed by the traditional method along the middle streamline. The axial position of the upper guide vane 2 and the lower guide vane 3 is the same as that of the original space guide vane. The hub body 4 is connected and fixed to the housing 1 through the fixed blades 6, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com