Novel melt-blowing production equipment

A production equipment and melt-blown technology, applied in spinneret assembly, filament forming process, filament/line forming, etc., can solve the problems of narrow nozzle width, low work efficiency, long residence time, etc., to achieve fluid pressure Reduce, improve work efficiency, the effect of uniform exit speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

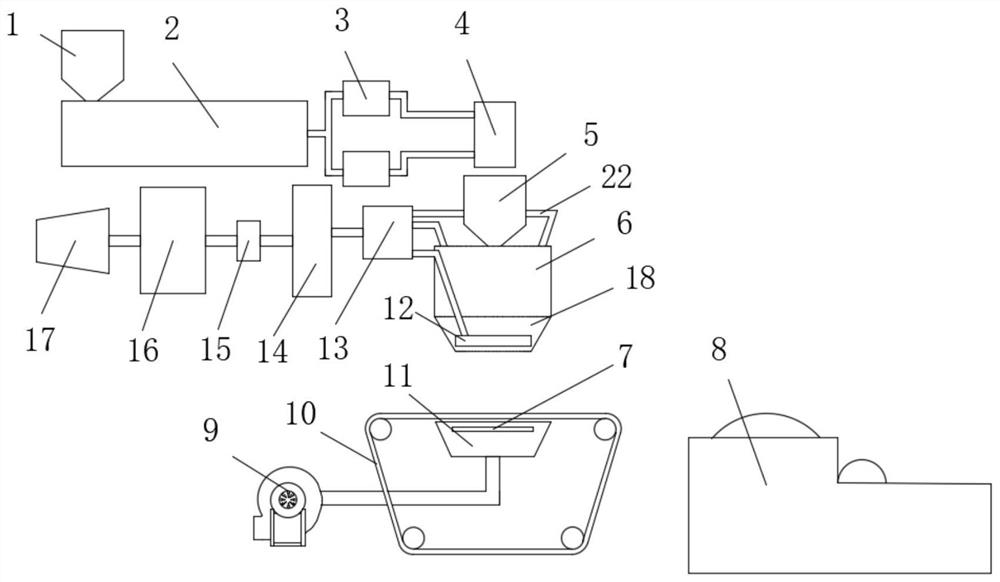

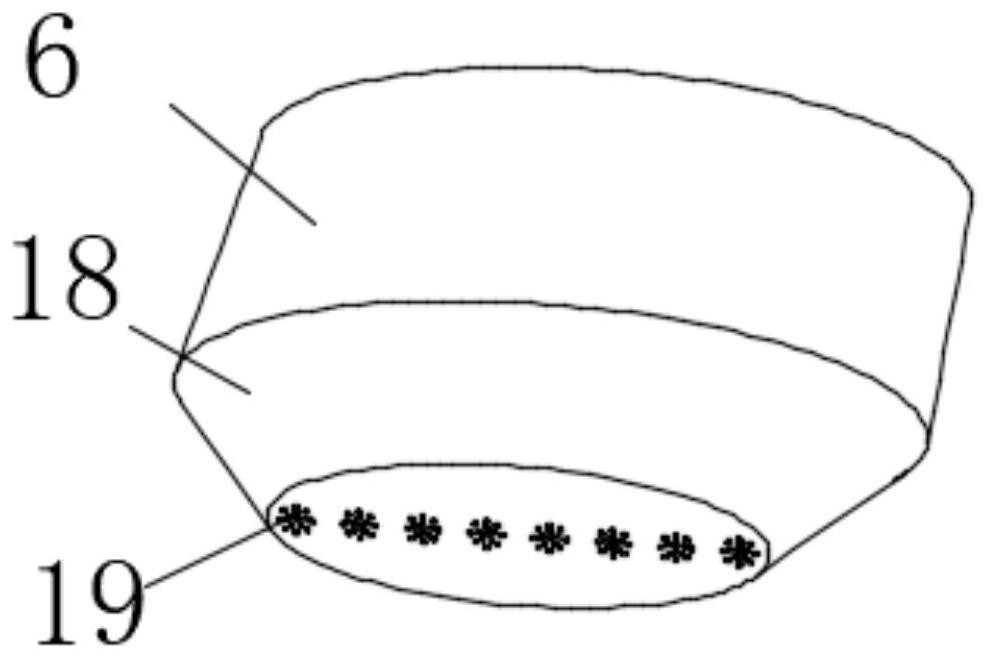

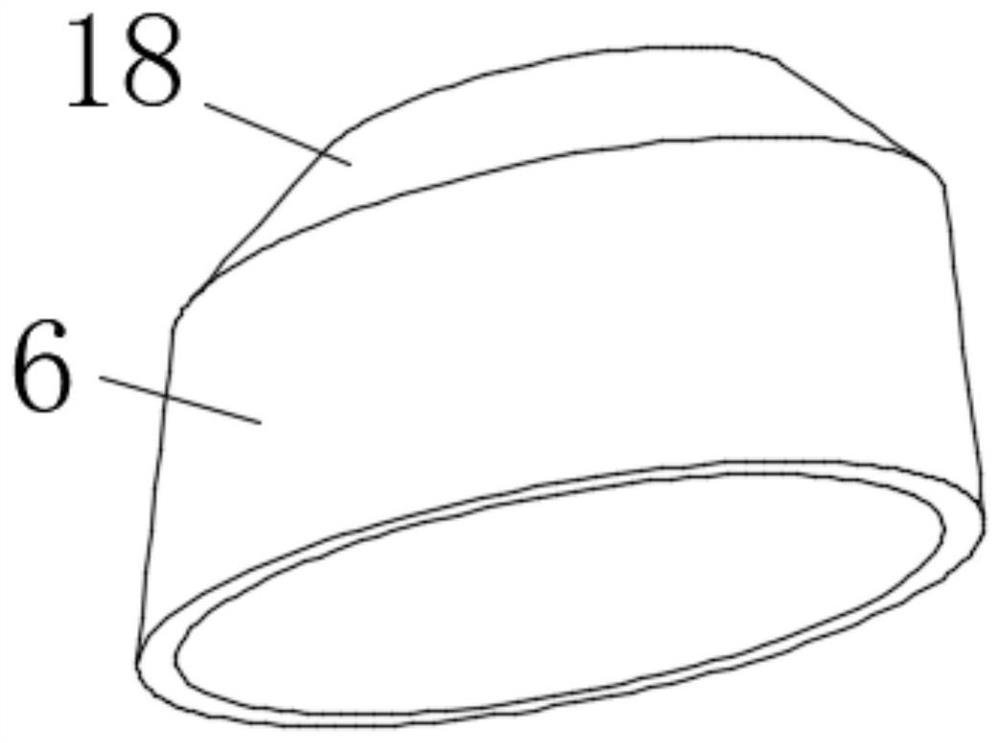

[0028] refer to Figure 1-4 , a new type of melt-blown production equipment, including a screw feeder 2, an elliptical manifold 6, a mesh belt receiver 10, an air compressor 17, and a trimming and winding machine 8, and the screw feeder 2 is connected through a plurality of pipelines. With the same gear metering pump 4, the bottom of the elliptical manifold 6 is fixedly connected with the nozzle 18, the gear metering pump 4 is located directly above the elliptical manifold 6, the mesh belt receiver 10 is located directly below the nozzle 18, and the trimming and winding machine 8 Located on one side of the mesh belt receiver 10, the air compressor 17 is connected to an air storage tank 16 through a pipeline, and the air storage tank 16 is connected to a heater 14 through a pipeline, and a device for distributing air The shunt component of the shunt.

Embodiment 2

[0030] refer to Figure 1-4 , a new type of melt-blown production equipment, including a screw feeder 2, an elliptical manifold 6, a mesh belt receiver 10, an air compressor 17, and a trimming and winding machine 8, and the screw feeder 2 is connected through a plurality of pipelines. With the same gear metering pump 4, the bottom of the elliptical manifold 6 is fixedly connected with the nozzle 18, the gear metering pump 4 is located directly above the elliptical manifold 6, the mesh belt receiver 10 is located directly below the nozzle 18, and the trimming and winding machine 8 Located on one side of the mesh belt receiver 10, the air compressor 17 is connected to an air storage tank 16 through a pipeline, and the air storage tank 16 is connected to a heater 14 through a pipeline, and a device for distributing air A splitter assembly for splitting the flow, the splitter assembly includes a flow divider 13 fixedly communicated with the heater 14 through a pipeline, and the fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com