Low mouth die accumulated material polyolefin alloy thermoplastic elastomer and manufacturing method thereof

A thermoplastic elastomer and polyolefin technology, used in the field of thermoplastic elastomers, can solve the problems of high EPDM viscosity, affecting the appearance of products, melt fracture, etc., to reduce die accumulation, reduce melt fracture, and reduce mold release inflated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

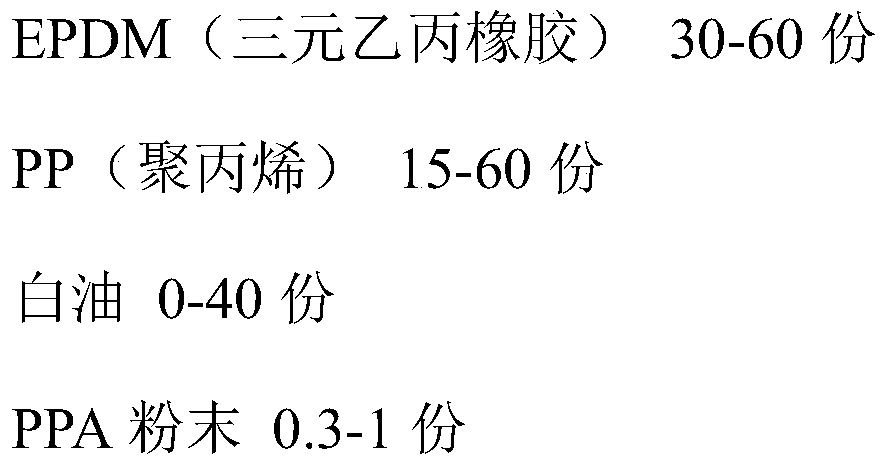

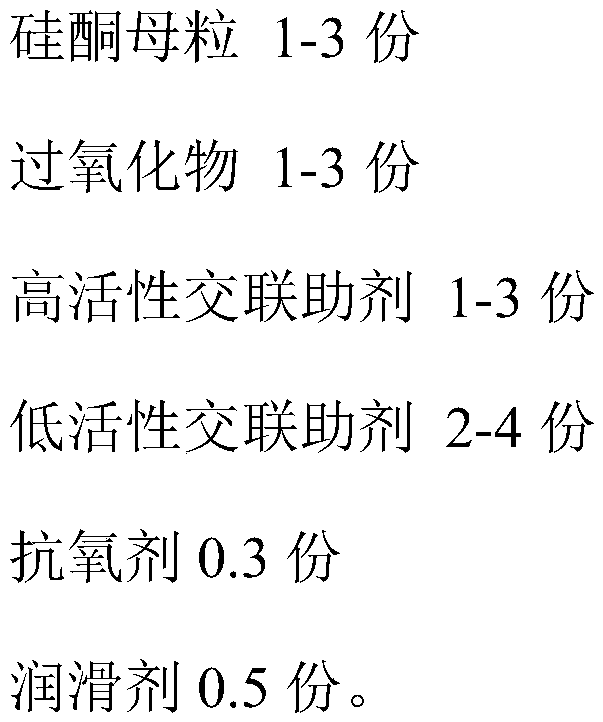

Method used

Image

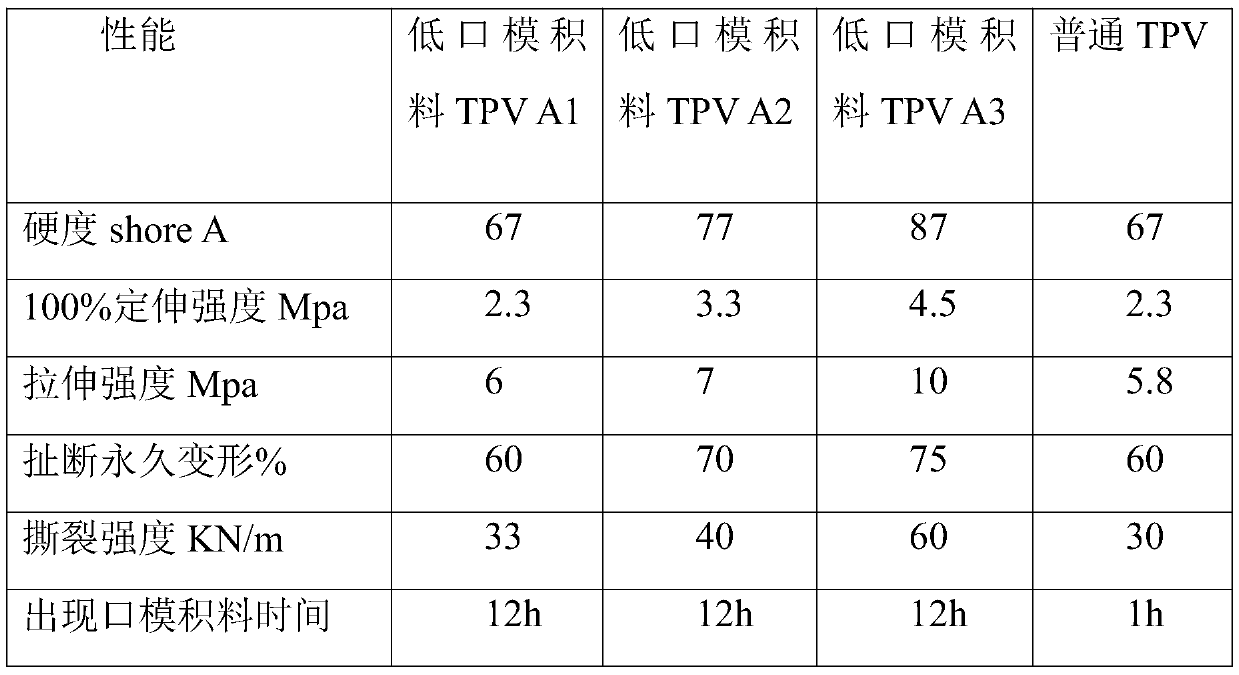

Examples

Embodiment 1

[0031] 40-50 parts of EPDM, 30-40 parts of white oil, 20-25 parts of PP, 0.5 parts of PPA, 1 part of silicone masterbatch, 0.5 parts of lubricant, 0.5 parts of DCP, 1 part of TAIC, 1,2 polybutylene Alkene, 0.3 parts of antioxidant.

[0032] 1. After weighing EPDM and PP on an electronic balance according to the above formula, put them into a low-speed stirring pot, add antioxidant and lubricant at the same time, and stir for 3 minutes.

[0033] 2. Put the mixture evenly stirred in 1 into a twin-screw extruder with an aspect ratio of 56, rotate at a speed of 300 rpm, and plasticize at a temperature of 190°C, and granulate to form a premix.

[0034] 3. Add the cross-linking agent DCP, high-activity co-cross-linking agent TAIC and low-activity co-cross-linking agent 1,2-polybutadiene weighed according to the above formula, and PPA powder, silicone masterbatch into the high-speed stirring pot 500 -600rpm, mixing for 3min.

[0035] 4. Put the mixture obtained in 3 into a twin-scr...

Embodiment 2

[0037] 40-50 parts of EPDM, 20-30 parts of white oil, 30-35 parts of PP, 0.5 parts of PPA, 1 part of silicone masterbatch, 0.5 parts of lubricant, 0.5 parts of BIPB, 1 part of TMPTMA, 1,2 polybutylene Alkene, 0.3 parts of antioxidant.

[0038] 1. After weighing EPDM and PP on an electronic balance according to the above formula, put them into a low-speed stirring pot, add antioxidant and lubricant at the same time, and stir for 3 minutes.

[0039] 2. Put the mixture evenly stirred in 1 into a twin-screw extruder with an aspect ratio of 56, rotate at a speed of 300 rpm, and plasticize at a temperature of 190°C, and granulate to form a premix.

[0040] 3. The cross-linking agent BIPB weighed according to the above formula, the high-activity auxiliary cross-linking agent TMPTMA and the low-activity auxiliary cross-linking agent 1,2-polybutadiene, as well as PPA powder and silicone masterbatch are added to the high-speed stirring pot 500 -600rpm, mixing for 3min.

[0041] 4. Put...

Embodiment 3

[0043] 30-35 parts of EPDM, 15-20 parts of white oil, 30-35 parts of PP, 0.5 parts of PPA, 1 part of silicone masterbatch, 0.5 parts of lubricant, 0.5 parts of BIPB, 1 part of TMPTMA, 1,2 polybutylene Alkene, 0.3 parts of antioxidant.

[0044] 1. After weighing EPDM and PP on an electronic balance according to the above formula, put them into a low-speed stirring pot, add antioxidant and lubricant at the same time, and stir for 3 minutes.

[0045] 2. Put the mixture evenly stirred in 1 into a twin-screw extruder with an aspect ratio of 56, rotate at a speed of 300 rpm, and plasticize at a temperature of 190°C, and granulate to form a premix.

[0046] 3. The cross-linking agent BIPB weighed according to the above formula, the high-activity auxiliary cross-linking agent TMPTMA and the low-activity auxiliary cross-linking agent 1,2-polybutadiene, as well as PPA powder and silicone masterbatch are added to the high-speed stirring pot 500 -600rpm, mixing for 3min.

[0047] 4. Put...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com