Extruding device of porous hard alloy profile

A technology of hard alloy and extrusion device, which is applied in the direction of metal extrusion, metal extrusion die, metal extrusion control equipment, etc. It can solve the problems of short profile length, large hole size, and air holes, etc., and achieve load reduction , Reduce extrusion resistance, good mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

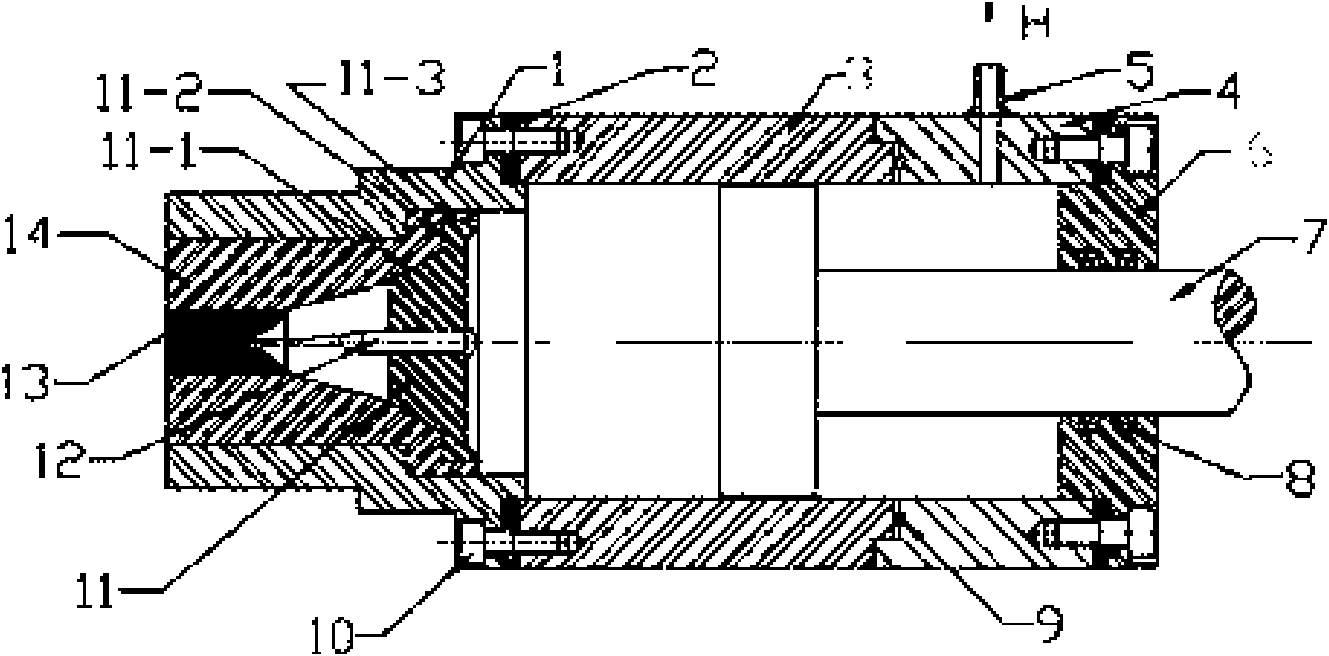

[0039] Example 1: Extrusion of Φ14mm×Φ1.5mm×300mm single-hole alloy rod

[0040] The perforated cemented carbide profile extrusion device of the present invention operates according to the workflow of mold loading, material loading, vacuuming, and extrusion:

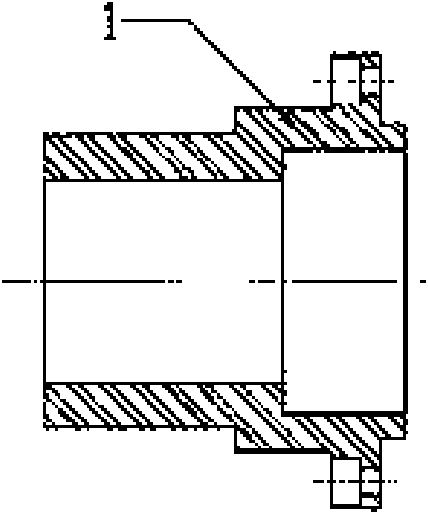

[0041] (1) Design and manufacture the mold, core rod and core rod support according to the outer circle and inner hole size of the alloy round rod, and grind the working surface of the above workpiece to a mirror surface; then install the mold formwork according to the steps.

[0042] (2) Use an adhesive tape to seal the mold outlet; withdraw the extrusion push rod; move out the front press cylinder 3 and lift the charging port upwards, pour alloy powder into the front press cylinder; put the press cylinder and extrusion Press the push rod to reset.

[0043] (3) Vacuumize to make the vacuum degree of the inner cavity of the cylinder reach 70Pa~80Pa.

[0044] (4) Start the machine and squeeze the alloy powder out of the m...

Embodiment 2

[0045] Example 2: Extrusion of Φ14mm×Φ1.5mm×300mm double-hole alloy round rod

[0046] The extrusion operation steps and the vacuum degree of the inner cavity of the press cylinder are consistent with the first embodiment.

[0047] The extrusion die used the mold of Example 1. When making mandrels, two mandrels were manufactured by splitting and placed on the mandrel support seat, and the mandrel support was manufactured according to the size of the mandrel support. The finish of the working surface is still mirror-like.

[0048] Install the mold according to the mold loading steps, operate according to the technological process of embodiment 1, and successfully extrude a Φ14mm×Φ1.5mm×300mm double-hole alloy round rod.

Embodiment 3

[0049] Example 3: Extrusion of 8mm×8mm×Φ1.0mm×300mm square single-hole profile

[0050] The extrusion operation steps and the vacuum degree of the inner cavity of the press cylinder are consistent with the first embodiment.

[0051] When making the mould, plan the size of the square cavity and mandrel according to the process parameters, and grind the working surfaces of the mold and mandrel to a mirror surface. Install the mold according to the mold loading steps, operate according to the technological process of the first embodiment, and successfully extrude the 8mm×8mm×Φ1.0mm×300mm square single-hole profile.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com