Hot extrusion forming method of copper alloy rail

A forming method, copper alloy technology, applied in the direction of metal extrusion dies, etc., can solve problems such as failure of forming methods, achieve good surface quality, improve physical and chemical properties and mechanical properties, and avoid scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the embodiments and the accompanying drawings. The protection scope of the present invention is not limited to the embodiments, and any changes made by those skilled in the art within the scope defined in the claims also belong to the protection scope of the present invention.

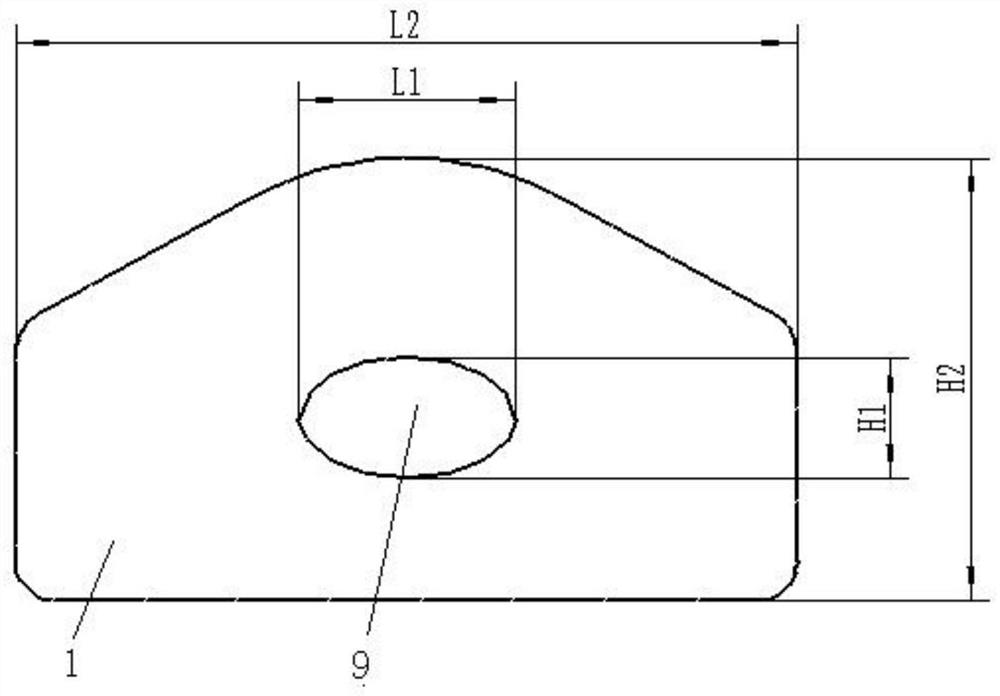

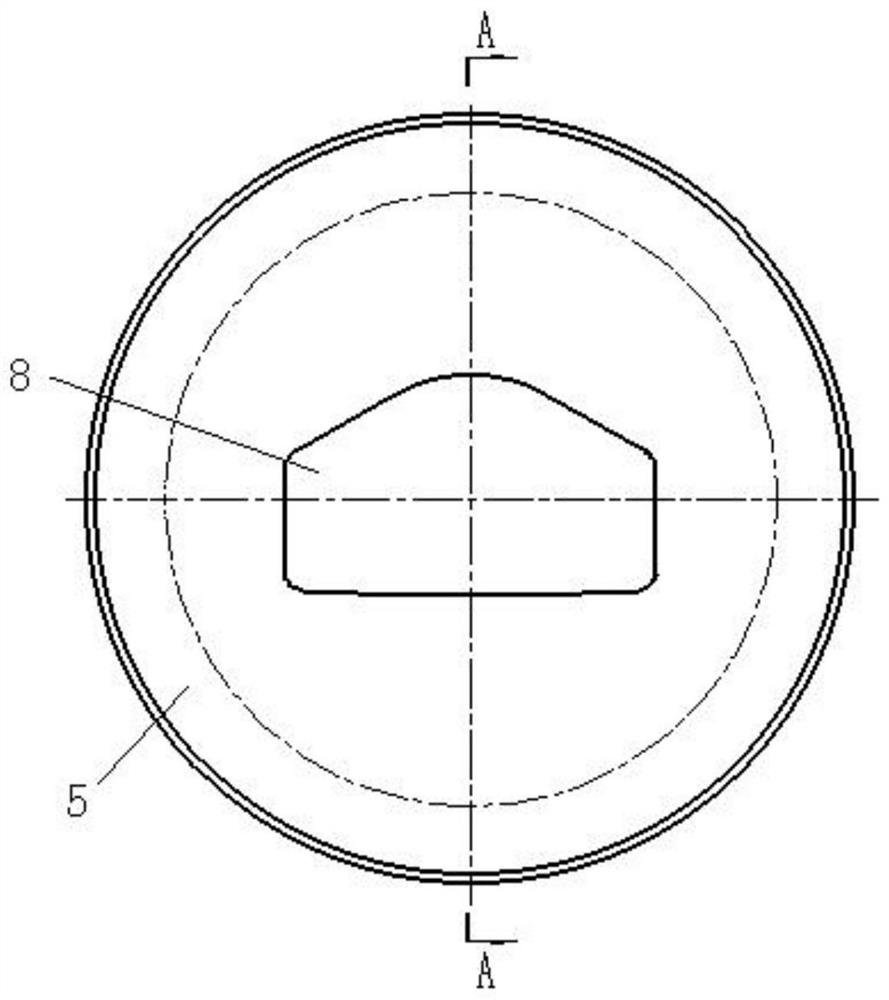

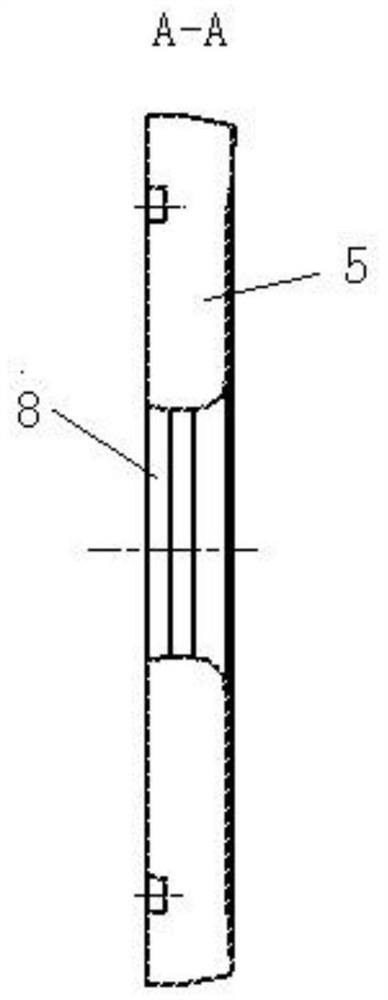

[0035] The mold used for hot extrusion molding of copper alloy track of the present invention is as Figure 2-8 Shown, comprise extrusion die 5, mandrel 2 and cold drawing die 13. The center of the extrusion die is provided with a mold cavity cover 8 , the hole pattern of the cavity cover is the same as the shape of the copper alloy rail 1 , and the cavity cover is provided with a gradually changing diversion arc. The head of the mandrel has a needle point 3 with the same shape as the track inner hole 9 of the copper alloy track, and the mold cavity cover and the needle tip of the mandrel head constitute the molding cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com