Server slide rail with automatic buckling device

An automatic buckle and server technology, applied in the field of server slide rails, can solve the problems of increasing the resistance and friction of extrusion, inconvenient operation and use, affecting the use performance, etc., to reduce resistance, improve stability, and reduce force arms. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

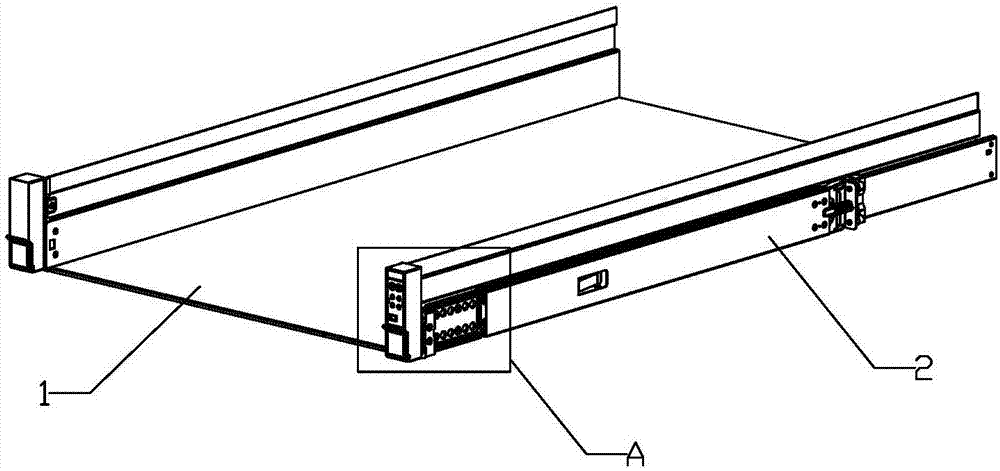

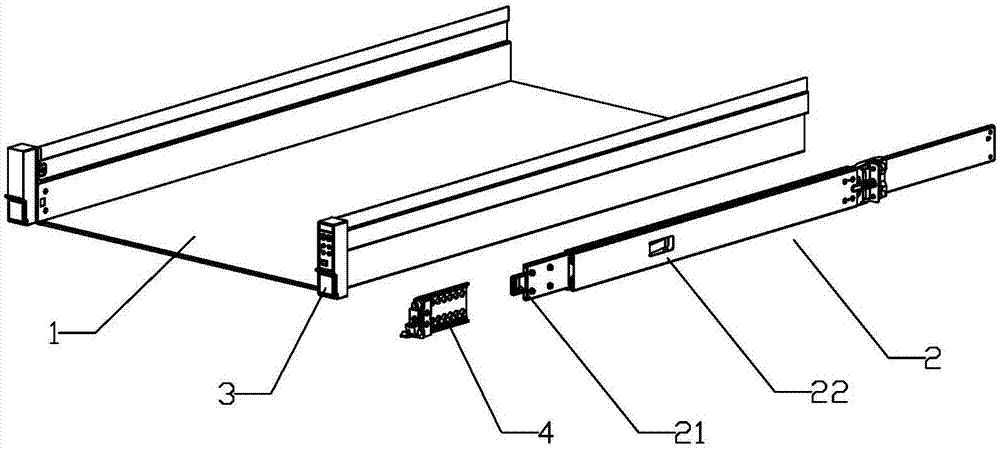

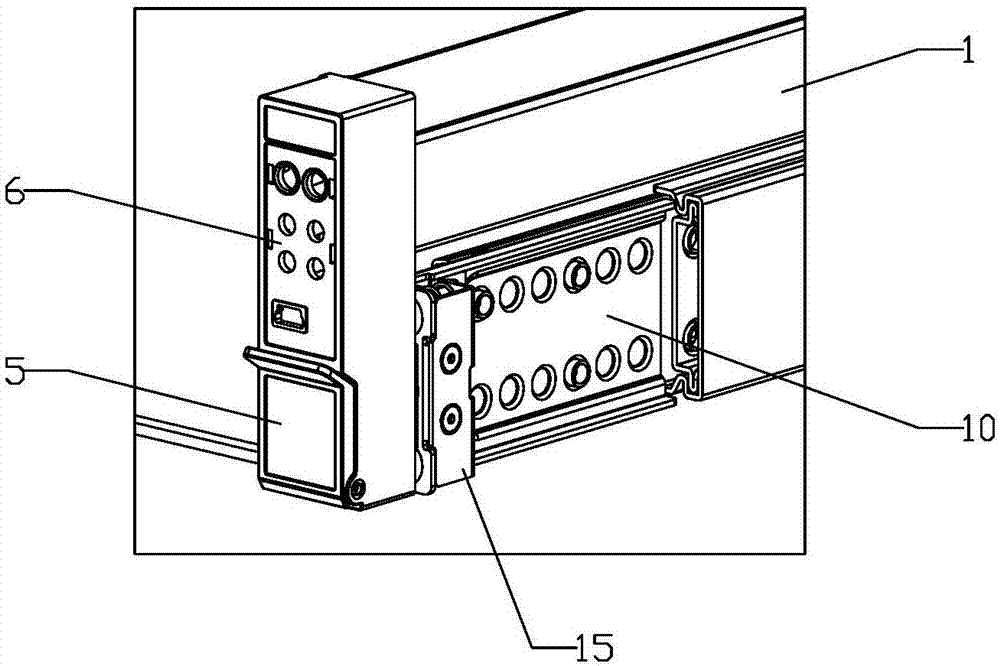

[0026] The present invention will be further described below in conjunction with accompanying drawing, according to Figure 1-Figure 10 As shown, the server slide rail with automatic fastening device of the present invention includes a drawer cabinet body 1 and a slide rail assembly 2, the slide rail assembly 2 includes an inner rail 21 and an outer rail 22, and the inner rail 21 relatively slides on the outer rail 22, The inner rail 21 is fixedly connected to the drawer cabinet body 1, and the outer rail 22 is fixedly connected to the frame a; an automatic buckling device is arranged between the drawer cabinet body 1 and the slide rail assembly 2, and the automatic buckling device includes a The lock component 3 and the buckle component 4 arranged on the outer rail 22, the lock component 3 and the buckle component 4 are mutually locked or unlocked. The outer rail 22 is fixedly connected to the frame a through the buckle assembly 4; the lock assembly 3 includes a buckle block ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com