Polymer melt shear vibration extrusion molding device

A technology of shear vibration and extrusion molding, which is applied in the field of polymer extrusion molding processing devices, can solve the problems of unsatisfactory ultrasonic vibration and the decline of mechanical properties of ultrasonic treatment, so as to improve production efficiency, avoid mechanical degradation, and change flow Effects of Denaturation and Condensed Matter Structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

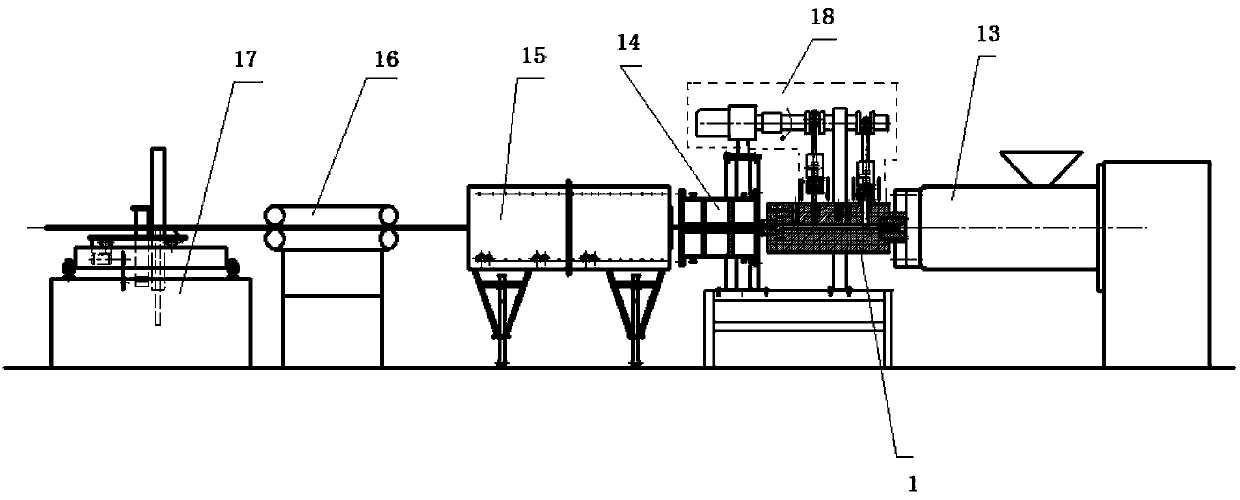

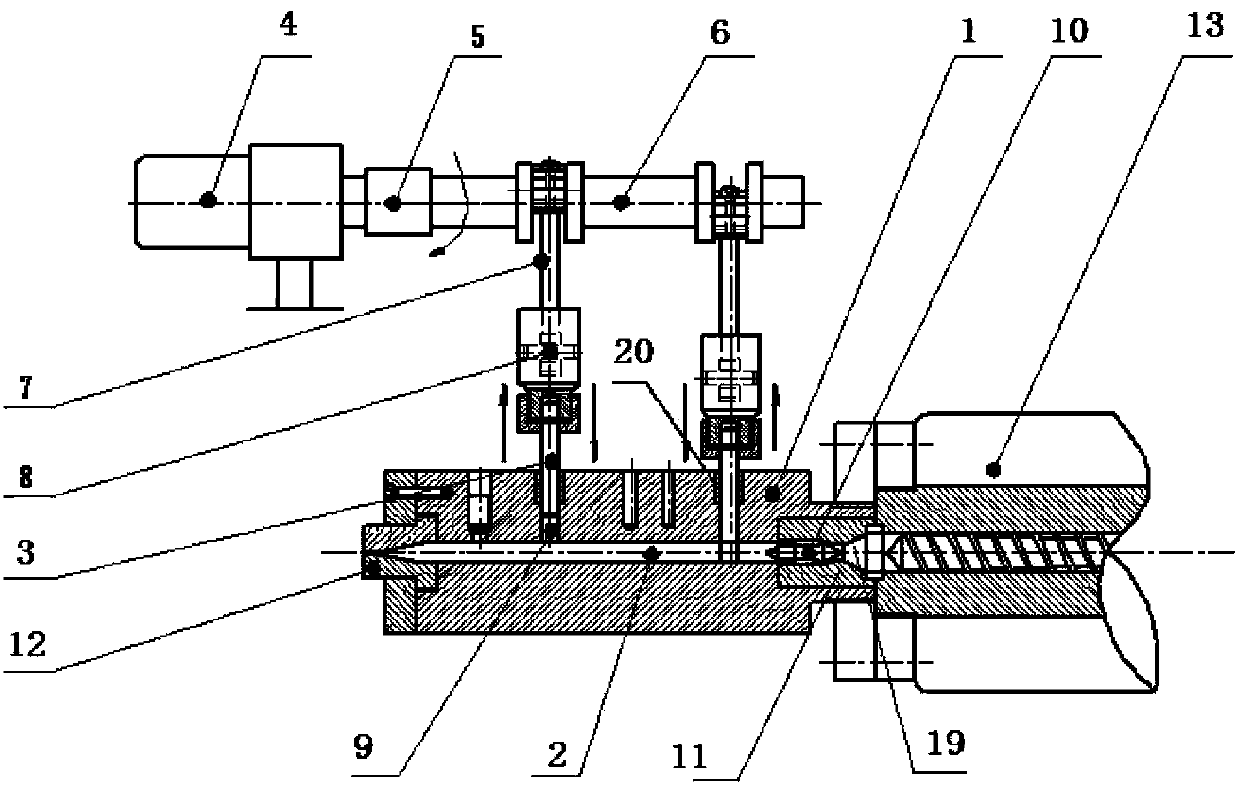

[0041] Such as figure 1 , 2 As shown, the polymer melt shear vibration extrusion molding device provided in this embodiment includes an extruder 13, an extruder head 1 connected to the extruder through a flange, a die 12, a calibrating die 14, Cooling water tank 15, traction device 16, cutting device 17 and the crank connecting rod shear vibration system 18 and the melt channel vibration cavity 2 in the extruder head 1 that are arranged on the extrusion head 1, wherein the crank connecting rod shear The cutting vibration system is composed of a crank connecting rod mechanism and a reciprocating vibration rod 3 .

[0042] The crank-link mechanism is composed of a continuously variable speed motor 4, a shaft coupling 5, a crank 6, a connecting rod 7 and a piston 8. The continuously variable speed motor 4 is connected with the crank 6 through a shaft coupling 5, and one end of the connecting rod 7 is connected through a connecting rod 7. The rod cover and the bolt are connected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com