Novel die for continuously extruding aluminum pipes, aluminum alloy pipes and special-shaped hollow profiles

A technology of hollow profiles and new molds, applied in the direction of metal extrusion molds, etc., can solve the problems of inconvenient introduction and flow of aluminum billets, uneven metal distribution and flow rate, easy damage to molds and cavities, etc., to achieve increased strength and improved Effect of temperature, reduction of extrusion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

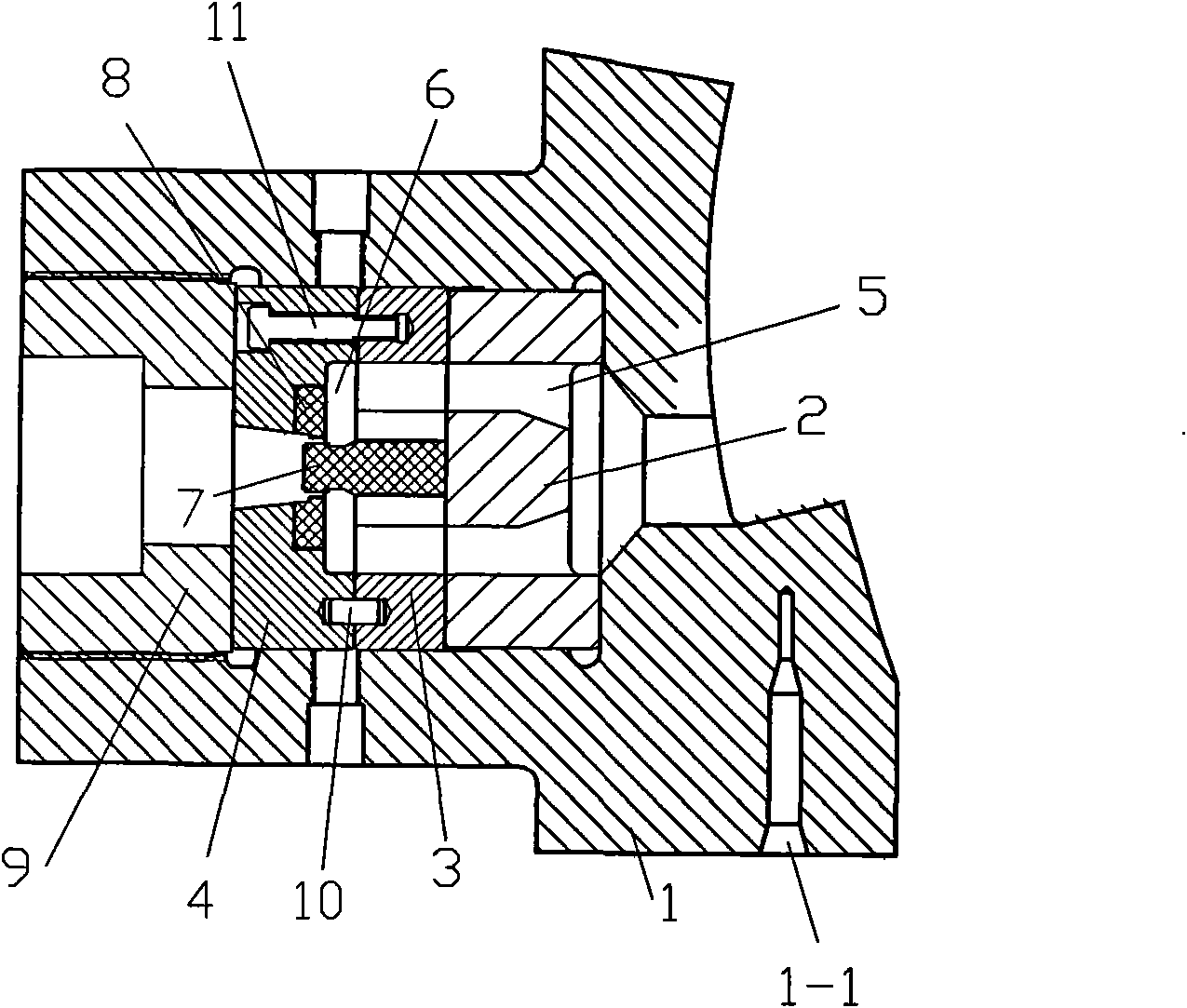

[0039] Below in conjunction with accompanying drawing and specific embodiment the utility model is described in further detail:

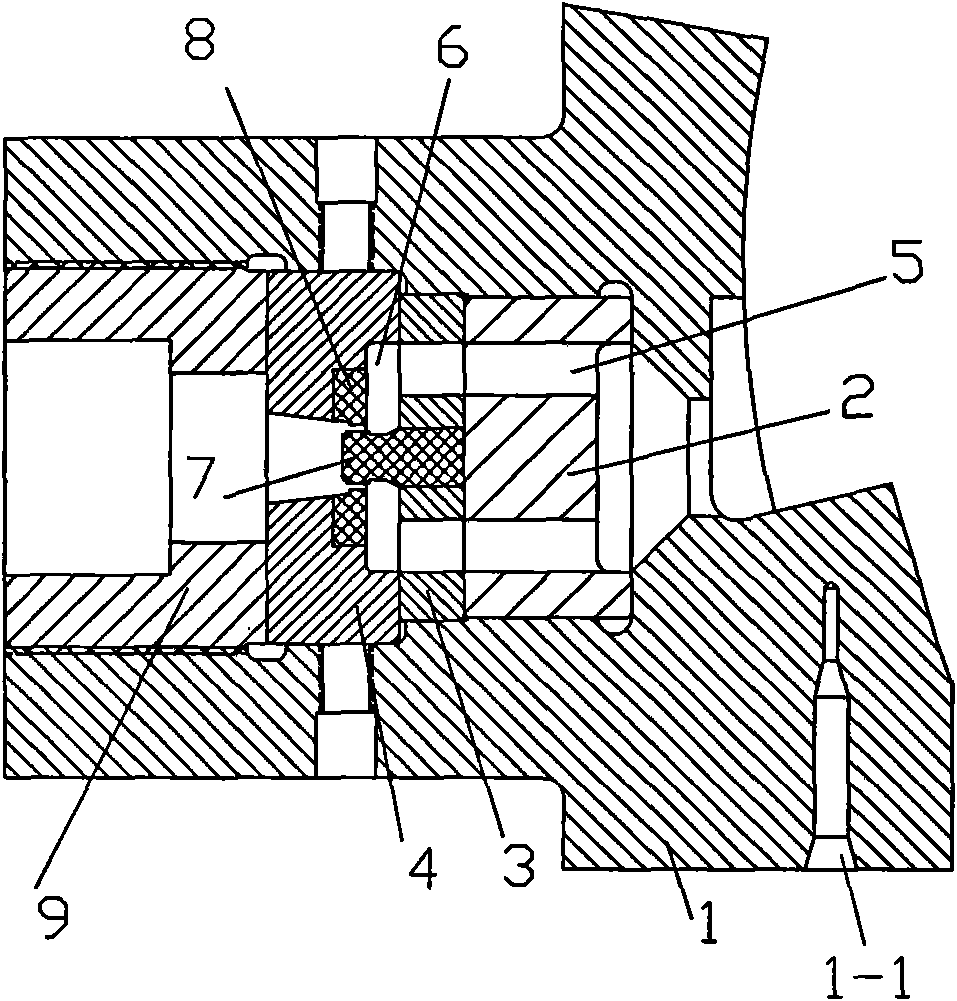

[0040] see figure 1 , Picture 1-1

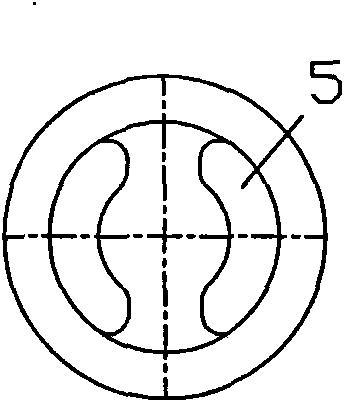

[0041] figure 1 It is a structural schematic diagram of the prior art; Picture 1-1 for figure 1 Front view of the profiled orifice in . exist figure 1 Among them, in the prior art, the mold for continuously extruding aluminum and aluminum alloy small and medium-sized pipes and special-shaped hollow profiles is set in the cavity 1, and the cavity 1 is a combined structure, which is at least divided into upper and lower parts, relying on fastening fastening, the mold is set in the cavity 1, including the upper mold 3 and the lower mold 4, the front deflector 2 provided on the upper mold 3 is at right angles, and the two sides of the front deflector 2 are respectively Be provided with a special-shaped shunt hole 5 (referring to Picture 1-1 ), the mold core 7 inlaid with the upper mold 3 forms the inner dia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com