Puffing machine for high starch materials puffing

A high-starch, puffing machine technology, applied in the field of food and feed machinery, can solve the problems of consumption of mechanical energy, inability to lengthen the screw, easy damage of the extrusion nozzle, etc., and achieve the effect of increasing production and reducing mechanical energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

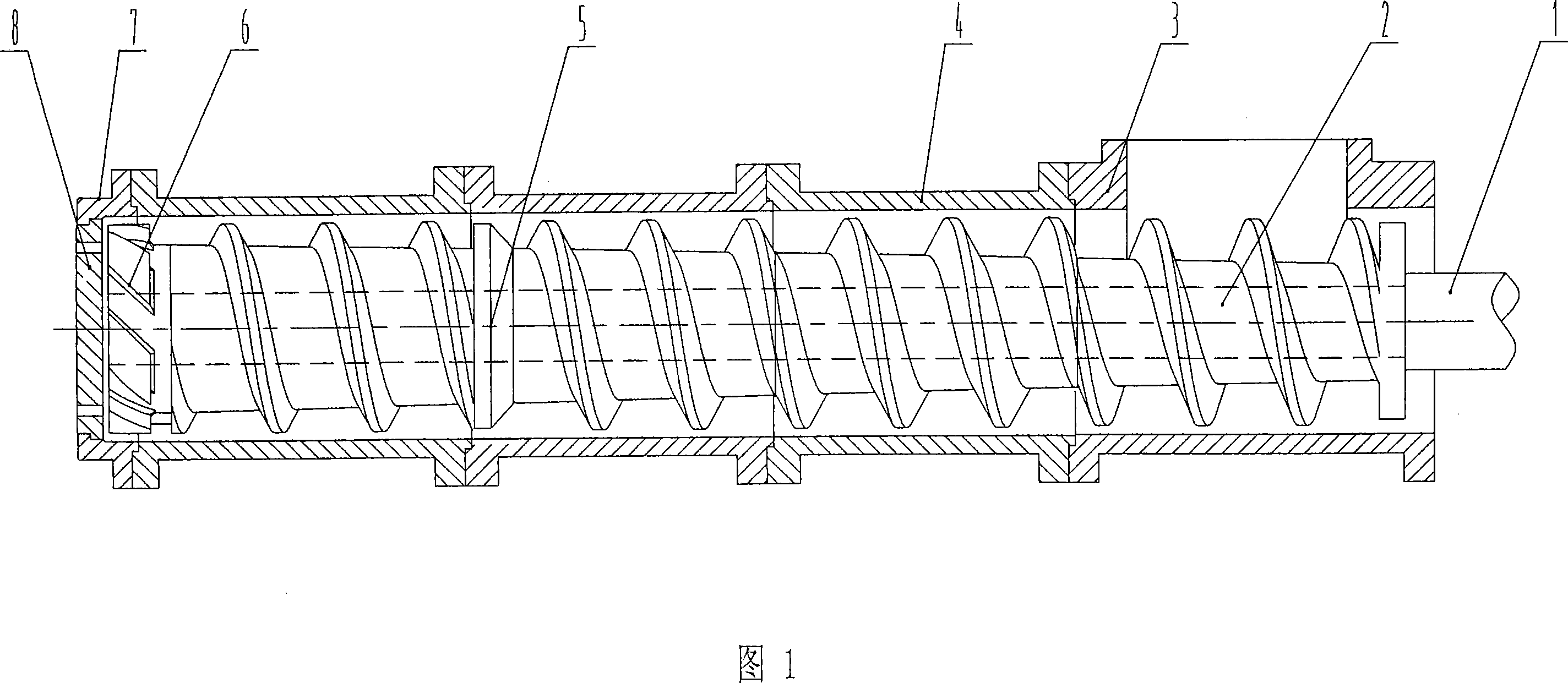

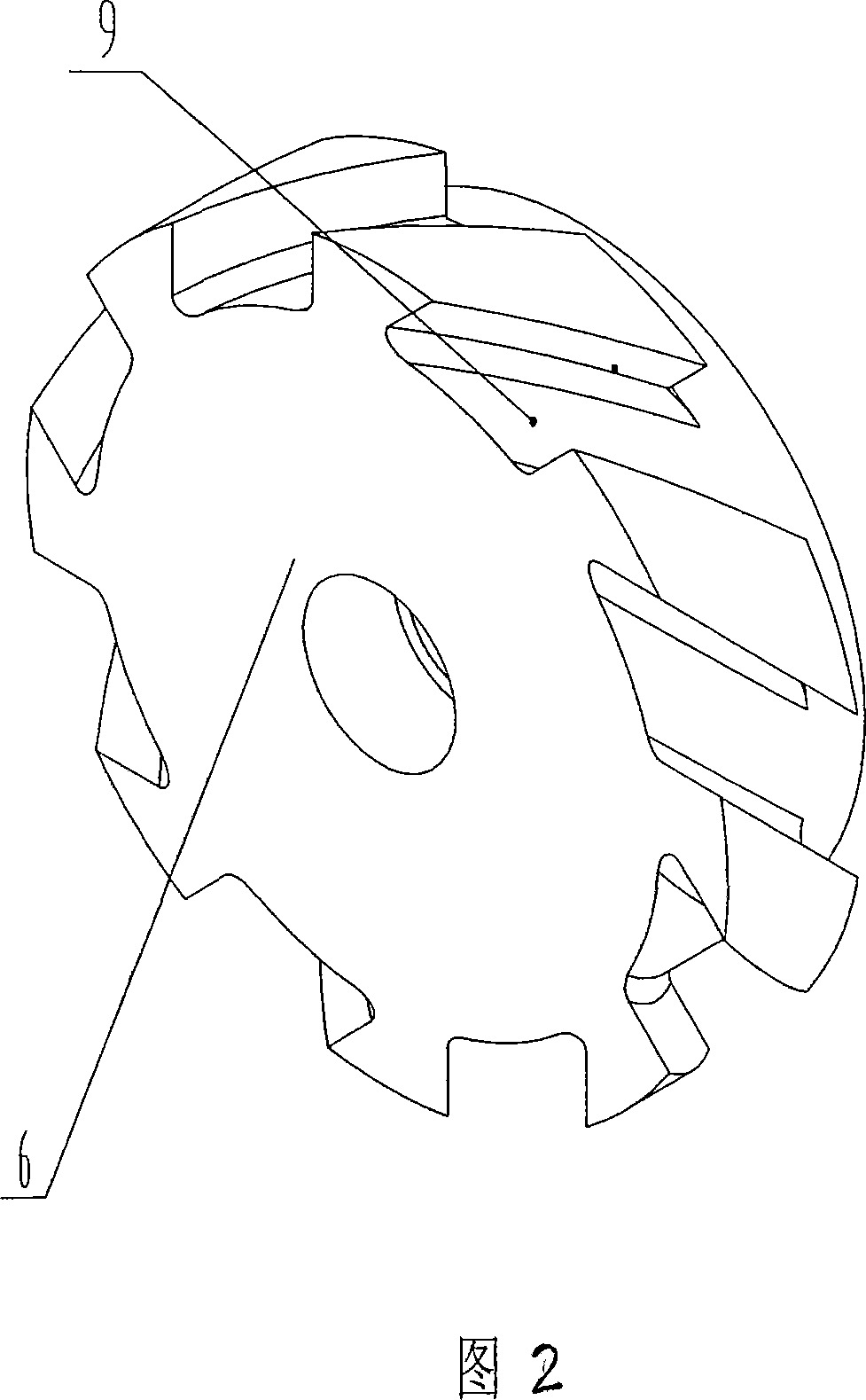

[0020] As shown in Figures 1 and 2, it is an extruder for extruding high-starch raw materials, including a main shaft 1, a pressure ring 5, a segmented screw 2, a feeding chamber 3, a segmented extrusion chamber 4, and a discharge device 7 and extrusion nozzle 8, the feeding chamber 3 is located at one end of the segmented extrusion chamber 4, the discharge device 7 is connected to the other end of the segmented extrusion chamber 4, and each section of the segmented screw 2 is set in sequence On the main shaft 1, the outer diameters of each section of the screw are equal, and the pressure ring 5 is arranged between at least two adjacent sections of the segmented screw 2, and one or two pressure rings can be provided; the segmented screw is sleeved The main shaft 1 of 2 extends into the segmented extrusion chamber 4 from one end of the feeding chamber 3, and the extrusion nozzle 8 is arranged on the discharge device 7 and is spaced from the end face of the segmented screw 2 at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com