Method and device for manufacturing cup-shaped component

A manufacturing method and technology of a manufacturing device, which are applied in the types of brakes, applications, household appliances, etc., can solve the problems of poor forming of the cylindrical part, poor precision of the concave and convex parts, and large extrusion resistance, and achieve extended life and reliable manufacturing methods. , the effect of efficient extrusion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example )

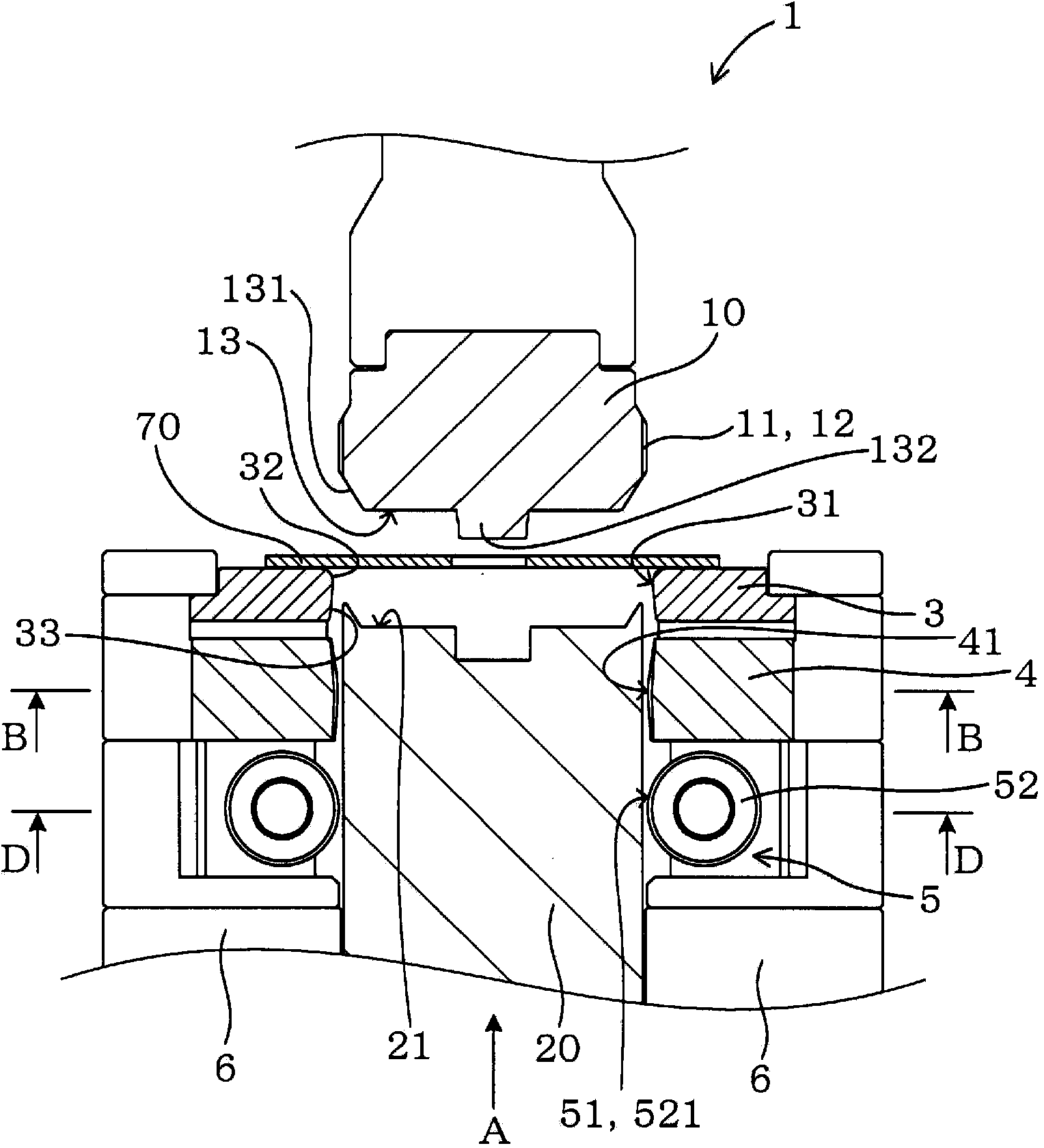

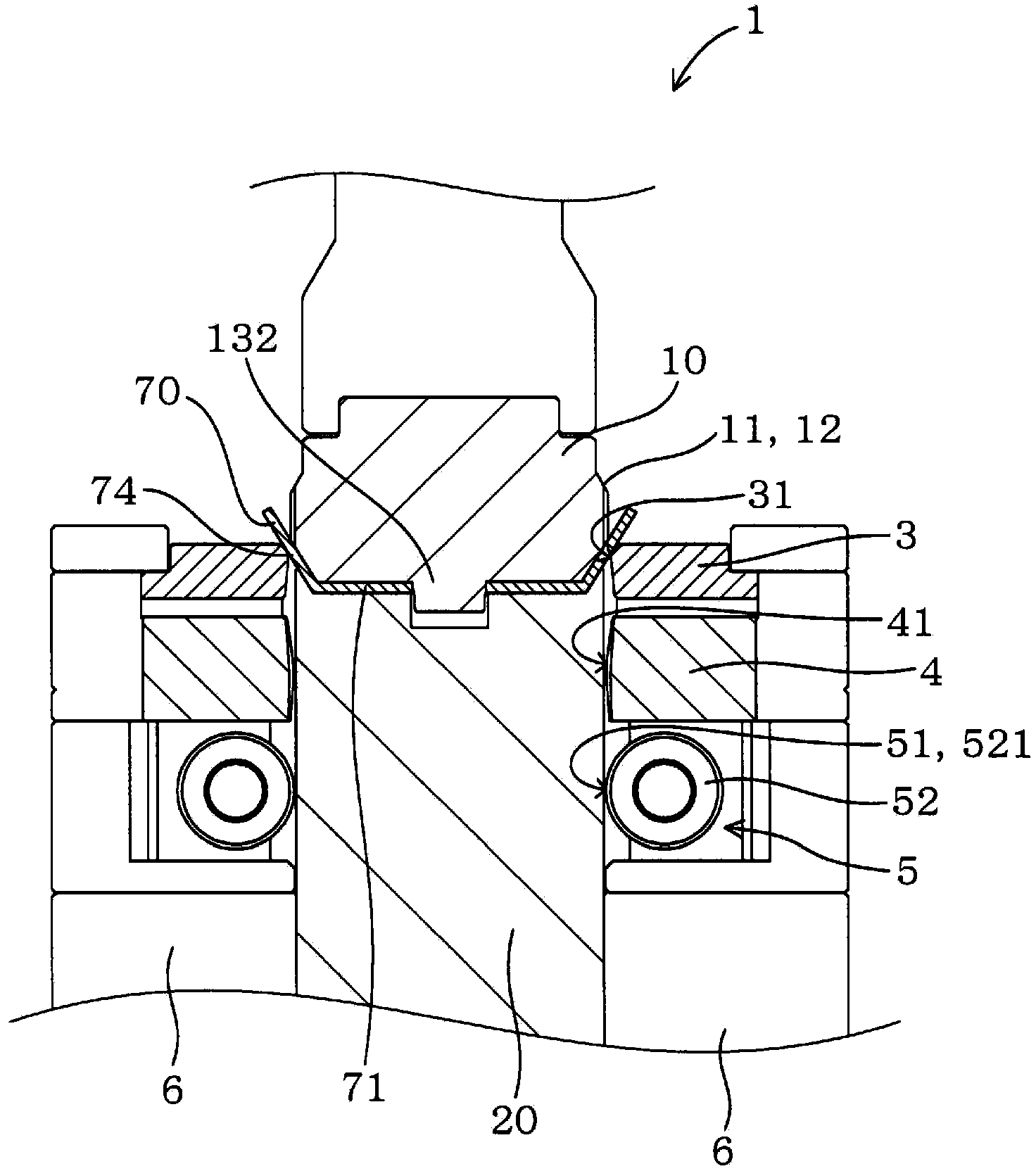

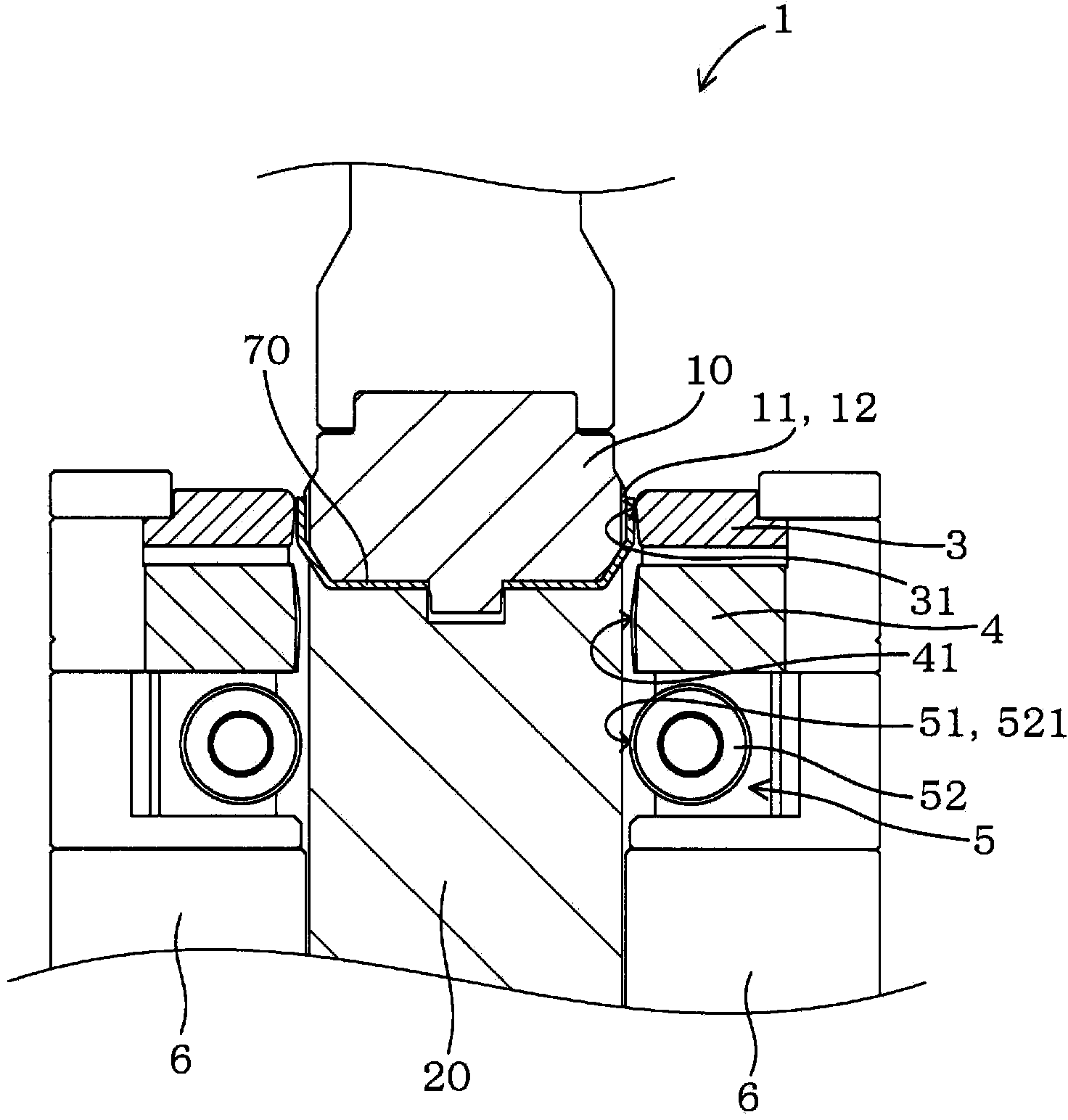

[0047] refer to Figure 1 to Figure 15 A method of manufacturing the cup-shaped member 7 having the concave-convex portion 721 and an embodiment of the manufacturing apparatus 1 will be described.

[0048] like Figure 15 As shown, the cup-shaped member 7 having the concavo-convex portion 721 has a disk-shaped bottom 71 and a cylindrical portion 72 erected from the bottom 71 . The cylindrical portion 72 has: a small-diameter portion 722 formed by denting the cylindrical portion 72 radially inward; a large-diameter portion 723 protruding radially outward compared with the small-diameter portion 722 ; The tooth surface 724 to which the portion 723 is connected.

[0049] like Figure 1 to Figure 5 As shown, the manufacturing device 1 of the cup-shaped member 7 has: a substantially cylindrical upper punch 10, which has an internal tooth forming part 12 corresponding to the inner peripheral shape of the concave-convex part 721 on its outer peripheral side 11; It has a drawing h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com