Blending device

A technology of homogenizer and storage chamber, which is applied in the field of poultry breeding, can solve the problems of low homogenization efficiency, high labor intensity, and affecting the healthy growth of chickens, and achieve high work efficiency, uniform feeding, and low labor intensity of workers Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

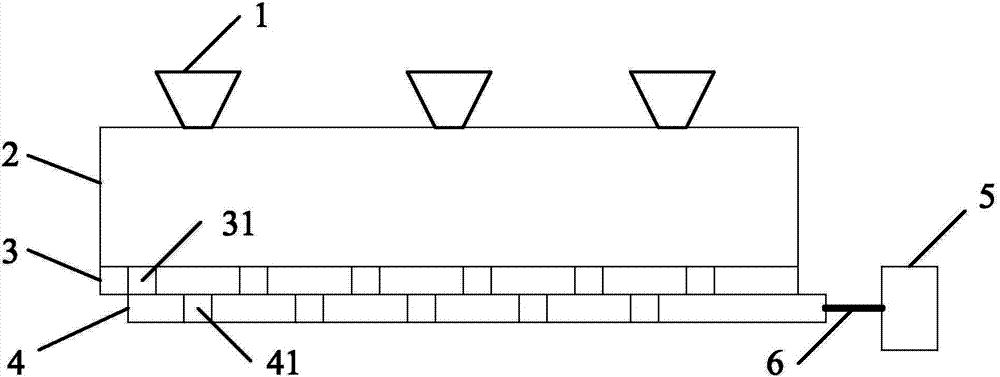

[0015] Such as figure 1 shown, figure 1 It is a structural diagram of a homogenizer proposed by the present invention.

[0016] refer to figure 1 , a kind of homogenizer that the present invention proposes, comprises feed inlet 1, material storage cavity wall 2, upper floor 3 and lower floor 4, and described upper floor 3 and described lower floor 4 are provided with even multiple outlets correspondingly. The material holes 31 and 41, the upper base plate 3 and the material storage chamber wall 2 form a material storage space, the lower base plate 4 is arranged close to the upper base plate 3, and a driving mechanism 5 is connected to the lower base plate 4 through a driving rod 6. exist

[0017] During the working process, first control the driving mechanism to drive the lower bottom plate 4 to slide, so that the discharge holes 31 and 41 of the lower bottom plate 4 and the upper bottom plate 3 are staggered, and then feed the material to the storage chamber through the fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com