A dry-process vertical electrostatic precipitator for gas

A technology of electrostatic precipitator and precipitator, which is applied in the direction of gas dust removal, separation method, electrostatic effect separation, etc. It can solve problems such as poor ash discharge, influence on equipment operation, and poor airflow uniformity of electric precipitator, so as to improve dust removal efficiency , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

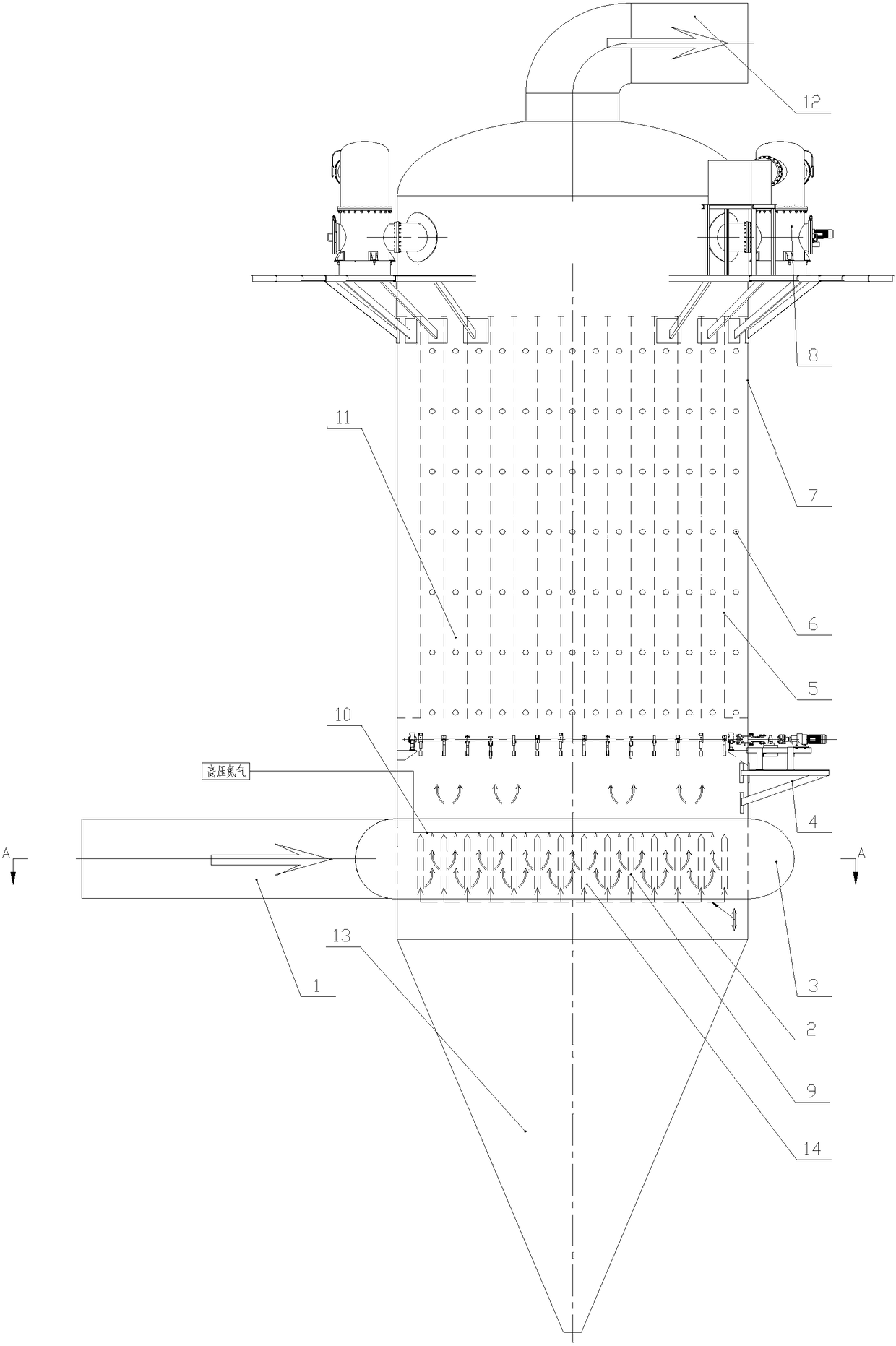

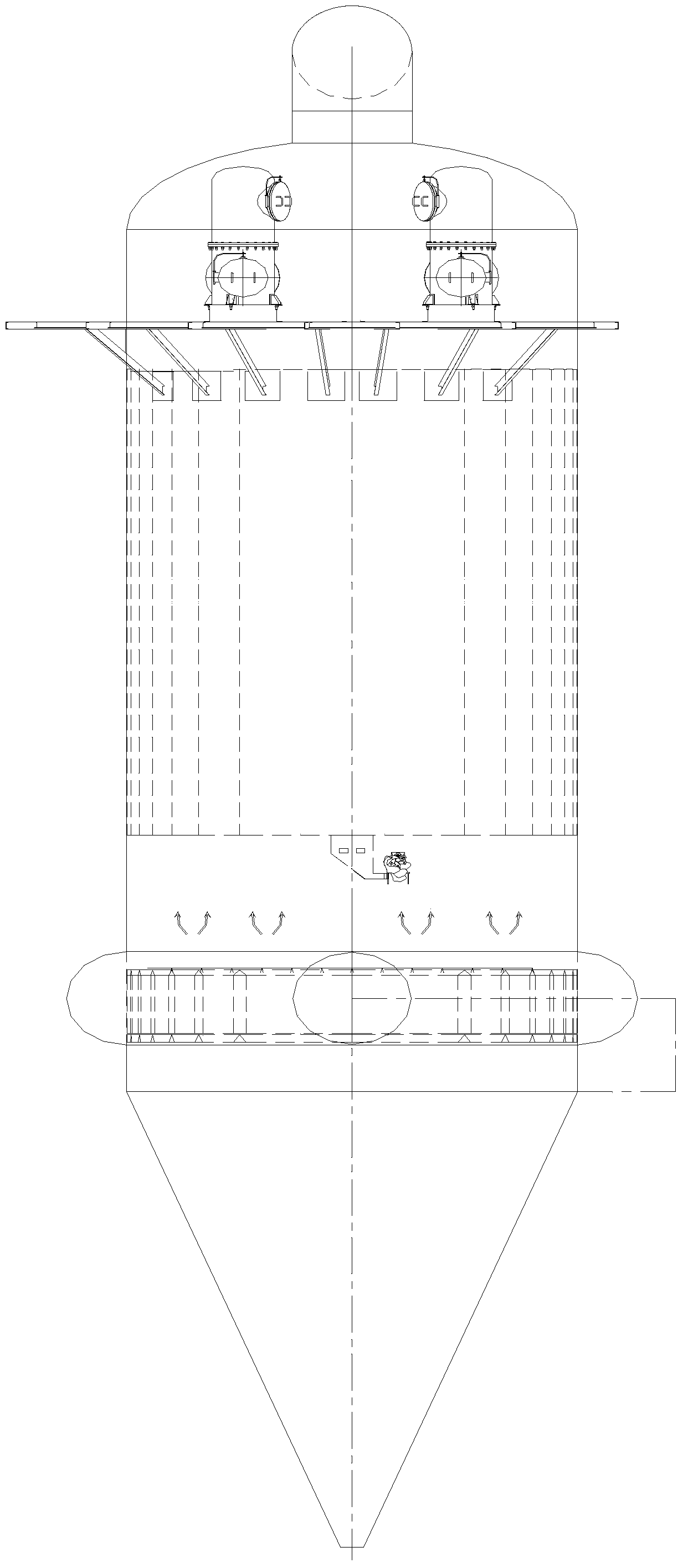

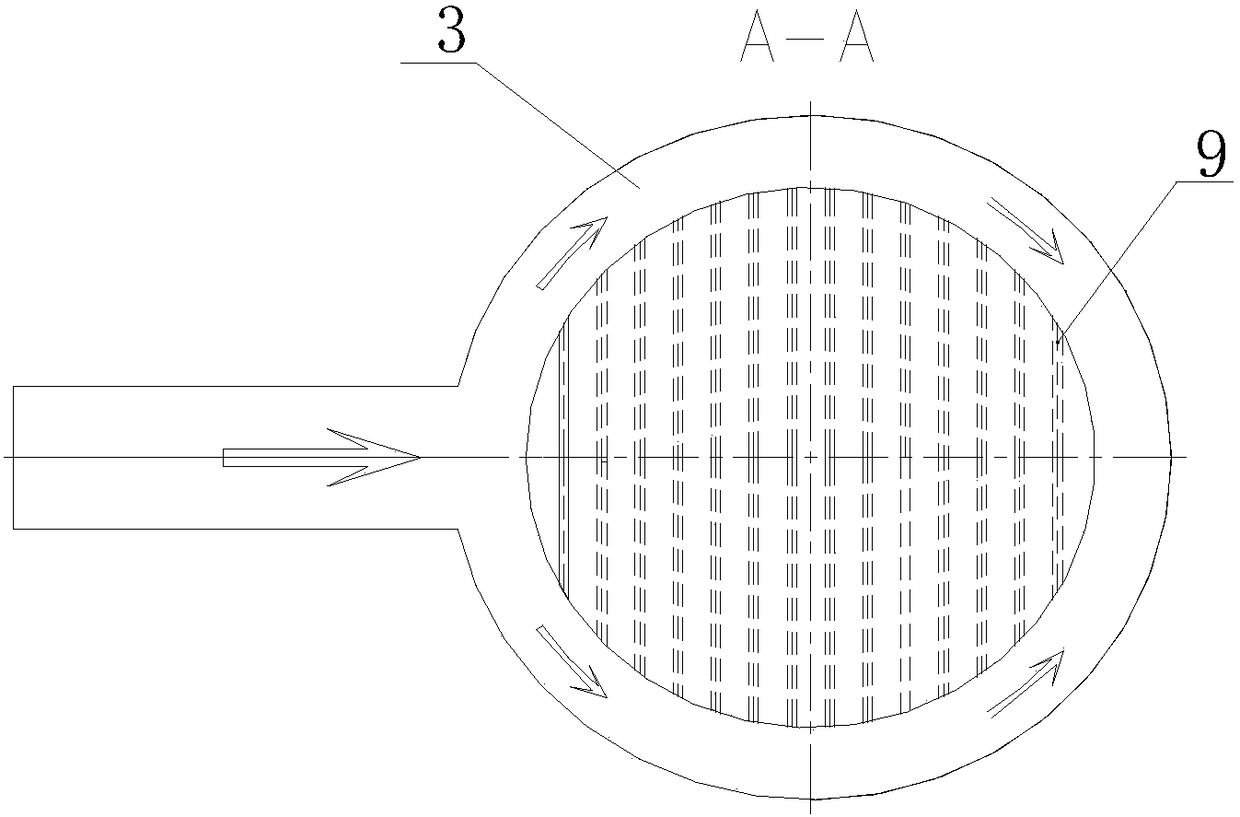

[0042] Such as Figure 1 to Figure 5 As shown, the present invention provides a dry-process vertical electrostatic precipitator for gas, comprising a dust collector body 7, the bottom of the dust collector body 7 is provided with an air inlet 1, and the bottom end is provided with an ash bin 13, and the upper part of the dust collector body 7 is also integrated There are anode plate 5, polar line, rapping device 4 and high-voltage power supply device 8. The top of dust collector body 7 is provided with air outlet 12, and the airflow direction is shown in the direction of the arrow in the figure.

[0043] The key point is that there is a ring-shaped flow guide pipe 3 on the bottom outer wall of the dust collector bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com