Wide bandgap semiconductor double-sided heat dissipation module packaging structure based on conductive metal band

A wide-bandgap semiconductor and conductive metal strip technology, applied in semiconductor devices, semiconductor/solid-state device components, and electrical solid-state devices, etc., can solve the problems of bond point connection failure, harsh heat dissipation environment, and large chip thermal resistance. Enhance current flow capacity, improve space utilization, reduce the effect of common source inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

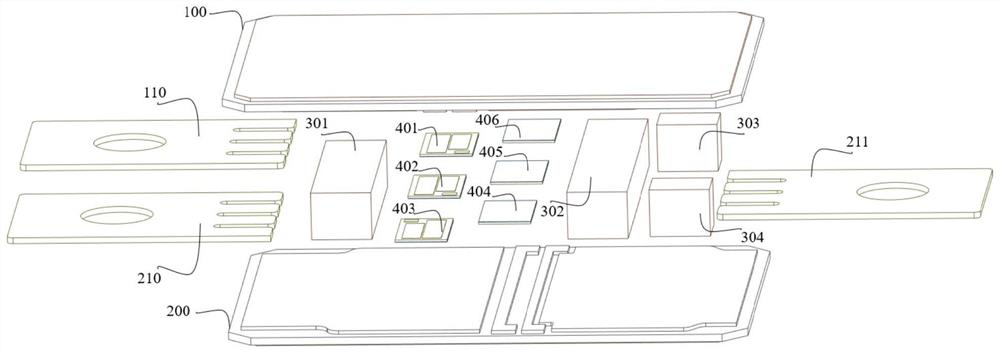

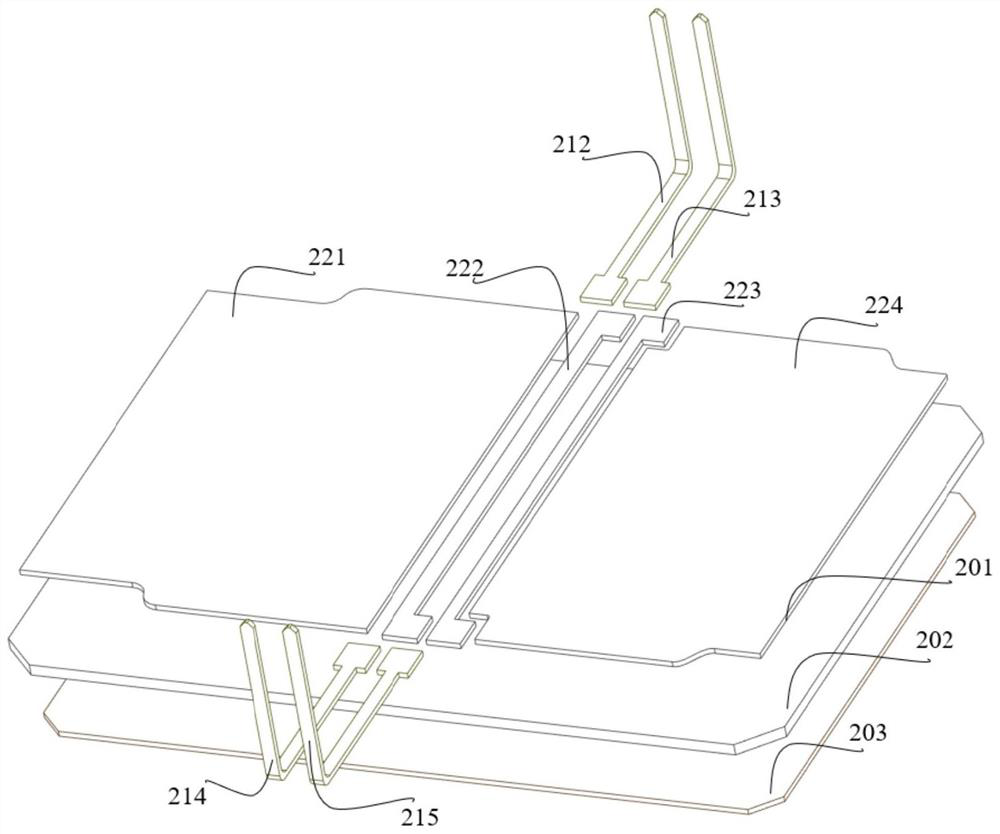

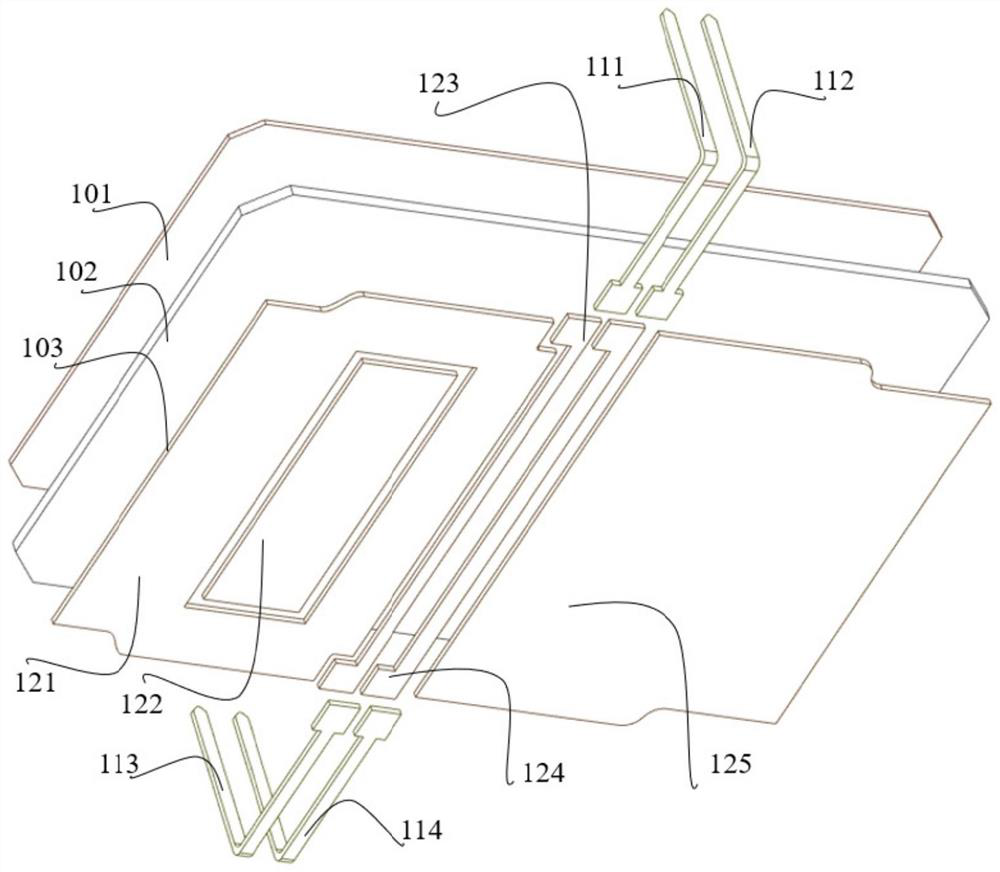

[0067] see figure 1 , figure 2 , image 3 and Figure 4 , the package structure of this embodiment includes 2 power substrates, 2 groups of 6 wide bandgap power semiconductor chips, 4 power pads, 3 power terminals, 8 drive terminals and 6 groups of conductive metal strips.

[0068] The two power substrates are specifically the top power substrate 100 and the bottom power substrate 200 .

[0069] The six wide-bandgap power semiconductor chips 400 are specifically a first high-arm wide-bandgap power semiconductor chip 401, a second high-arm wide-bandgap power semiconductor chip 402, a third high-arm wide-bandgap power semiconductor chip 403, The first lower arm wide bandgap power semiconductor chip 404 , the second lower arm wide bandgap power semiconductor chip 405 and the third lower arm wide bandgap power semiconductor chip 406 .

[0070] The four power pads are specifically a DC side power pad 301 , an AC side main power pad 302 , an AC side auxiliary power pad 303 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com