Solid waste sorting equipment and treatment system

A solid waste and sorting technology, which is applied in solid separation, grain treatment, and separation of solids from solids with airflow, etc., can solve the problem of low efficiency of winnowing and the inability to achieve accurate separation and separation of waste and solid waste. Incomplete selection and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

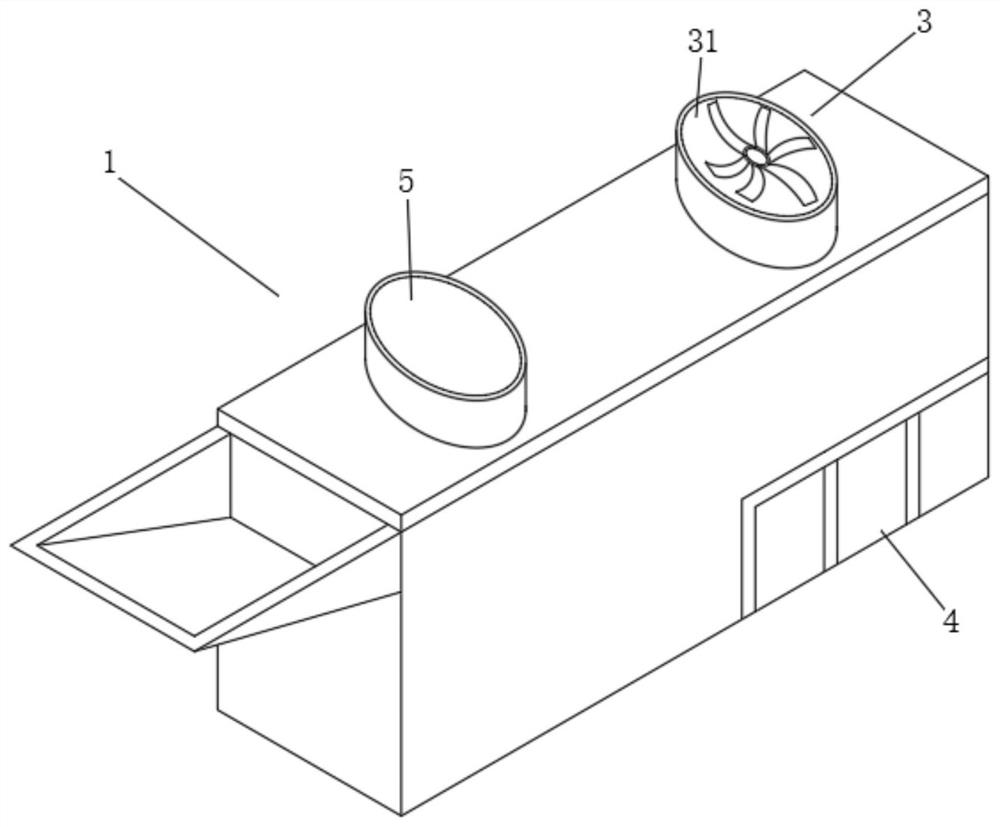

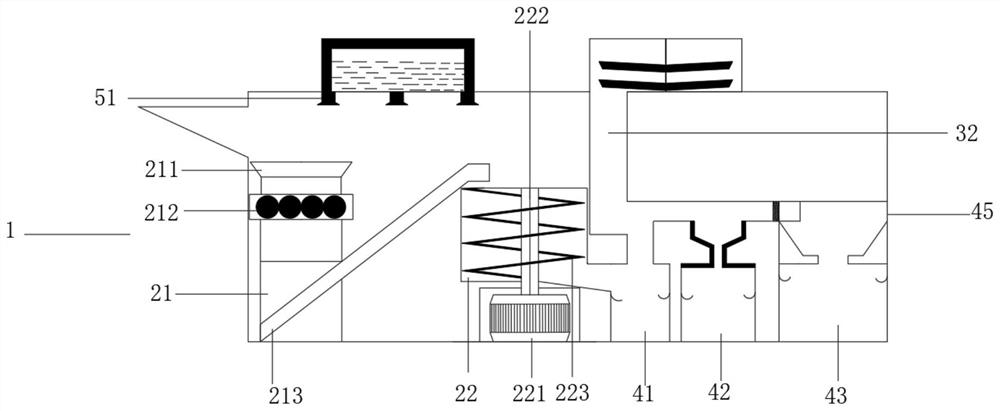

[0023] A kind of solid waste sorting equipment and treatment system, in order to solve the problem of traditional sorting is not thorough, the efficiency of winnowing is not high and can not achieve accurate sorting of waste solid waste, as a preferred embodiment, such as figure 1 and figure 2 As shown, a sorting device 1 is included, and the sorting device 1 includes a solid waste crushing mechanism 2, a winnowing mechanism 3, and a sorting box 4. The solid waste crushing mechanism 2 includes a first crushing mechanism 21 and a second crushing mechanism 22. The first Pulverizing mechanism 21 comprises feeding inlet 211, reel 212, conveyer belt 213, and the bottom of first pulverizing mechanism 21 is provided with the one side of conveyer belt 213, and conveyer belt 213 is arranged obliquely, and the bottom of the other side of conveyer belt 213 is provided with the second pulverizer. Mechanism 22, the second pulverizing mechanism 22 is provided with motor 221, connecting sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com