A pharmaceutical capsule grinding and polishing machine

A polishing machine and capsule technology, which is applied in surface polishing machine tools, grinding/polishing equipment, grinding/polishing safety devices, etc., can solve the problems of poor polishing effect, difficult selection of empty shell capsules, etc., and achieve prolonged polishing time, increase the polishing particle size, and improve the efficiency of winnowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

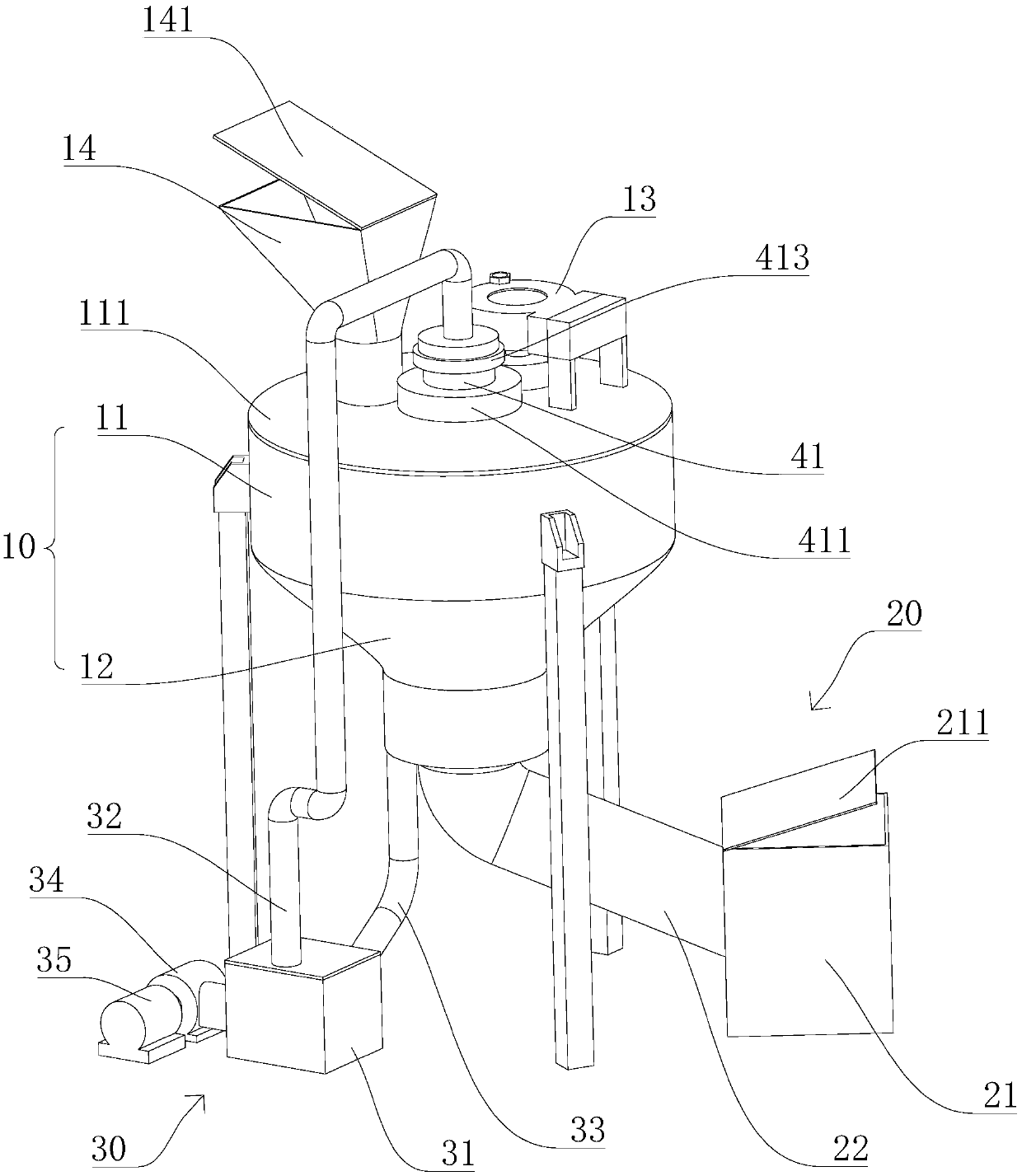

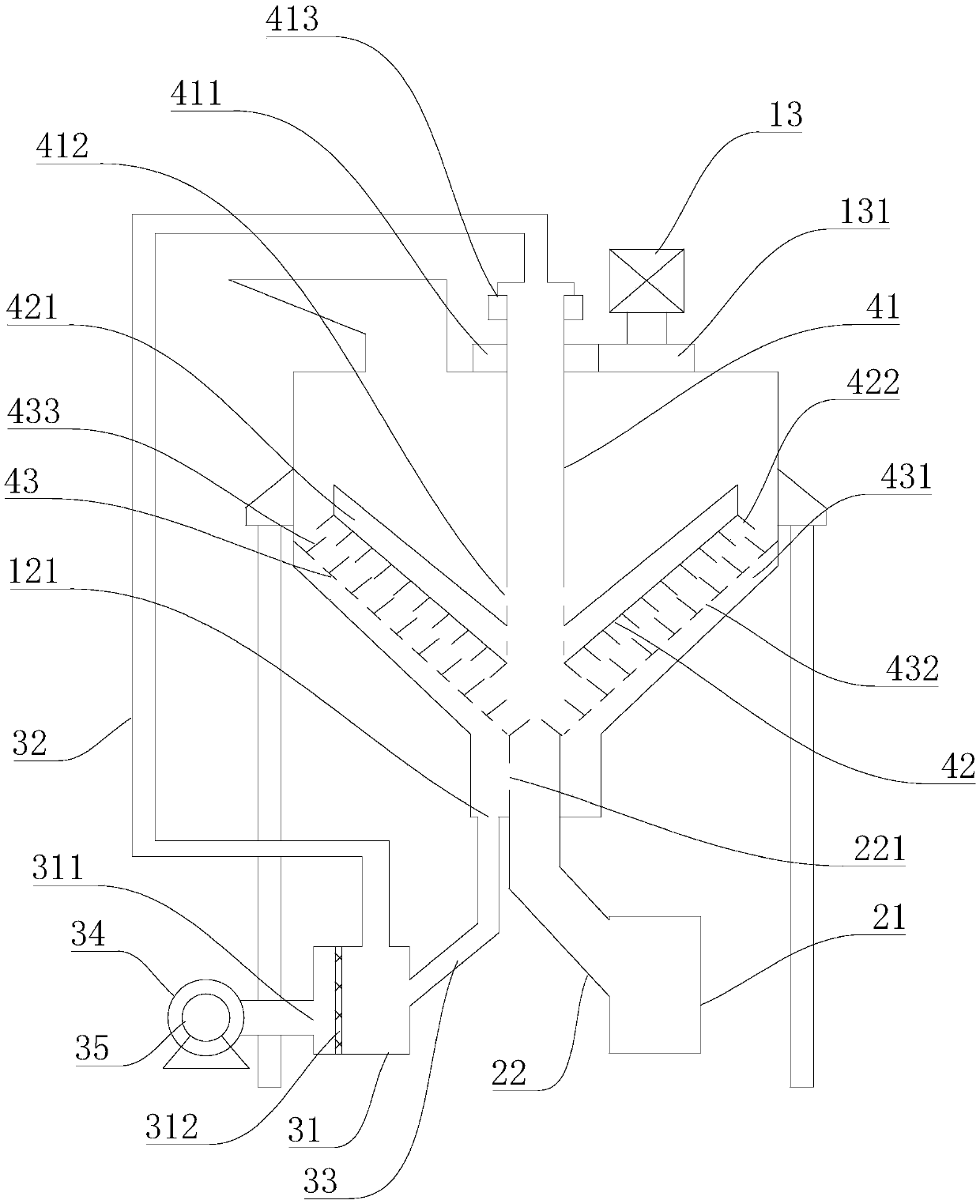

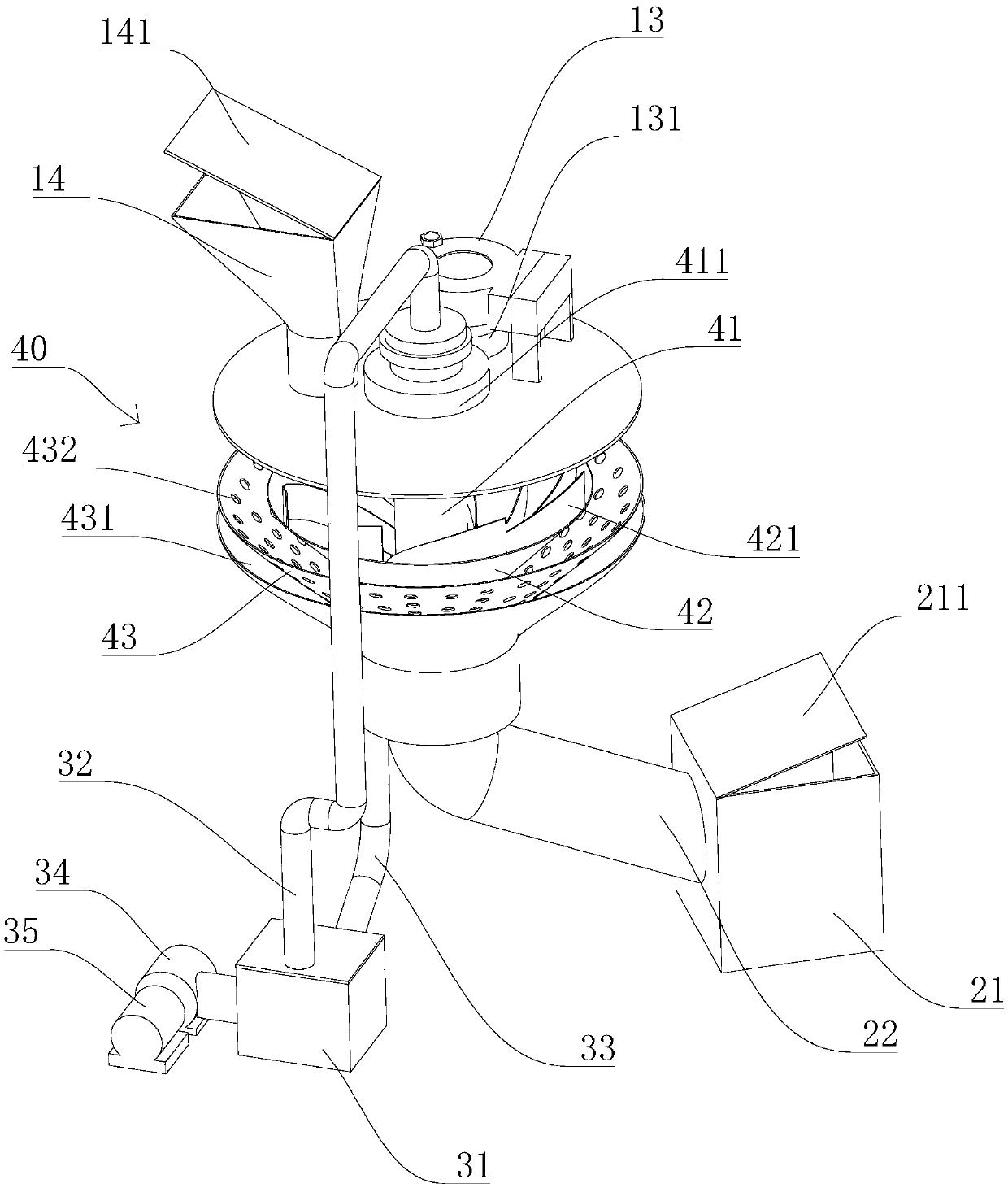

[0023] Please refer to attached Figure 1 to Figure 4 , the embodiment of the present invention provides a pharmaceutical capsule grinding and polishing machine, comprising a body 10, a material receiving mechanism 20 positioned below the body 10, and a waste collection mechanism 30 positioned below the body 10; the body 10 is vertically arranged, and the body 10 It includes a first end 11 located above and a second end 12 located below; the first end 11 is a hollow cylinder, the top of the first end 11 is provided with an access cover 111, and the upper surface of the access cover 111 is provided with a first drive Motor 13 and feed hopper 14, feed hopper 14 communicates with the inside of body 10; Second end 12 is a hollow cone, the top of second end 12 is fixedly connected with the bottom of first end 11, the bottom of second end 12 The cross-sectional area gradually decreases from an end close to the first end 11 to an end far away from the first end 11; the inside of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com