A light-weight debris separation system for construction waste recycling

A construction waste and separation system technology, applied in the field of light debris separation systems, can solve the problems of non-targeting, high impurity removal efficiency, low equipment efficiency, etc., and achieves a small occupied area, high impurity removal efficiency, and simple structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

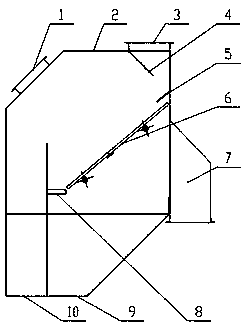

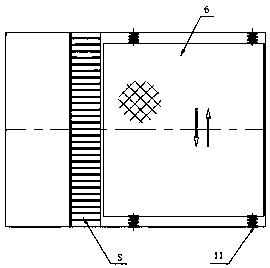

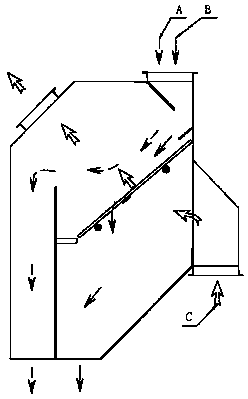

[0024] see figure 1 , The invention discloses a light foreign matter separation system used for regeneration treatment of construction waste. As shown in the figure: it includes a casing 2 with a feed inlet 3 on the top of the casing 2, and a feed baffle 4, a bulk material plate 5 and a vibrating screen are arranged in sequence below the feed inlet 3 in the casing 2 6. The bottom side of the vibrating screen 6 is provided with a grate partition 8, and below the vibrating screen 6 and the grate partition 8 is a material outlet 9 arranged on the casing 2; the casing 2 is provided with an air inlet 7 And the air outlet 1, the air inlet 7 and the air outlet 1 are respectively located on both sides of the casing 2 separated by the vibrating screen 6, wherein: the air inlet 7 is located under the side of the vibrating screen 6, and the air outlet 1 is located at the side of the vibrating screen 6 above the side of the air outlet 1; the bottom of the air outlet 1 is provided on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com