A kind of superfine fly ash production system and production process

A technology of ultra-fine fly ash and production system, applied in the direction of solid separation, separating solid from solid with air flow, chemical instruments and methods, etc., can solve problems such as low reactivity and quality to be improved, and reduce humidity , improve the efficiency of grinding and winnowing, and improve the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

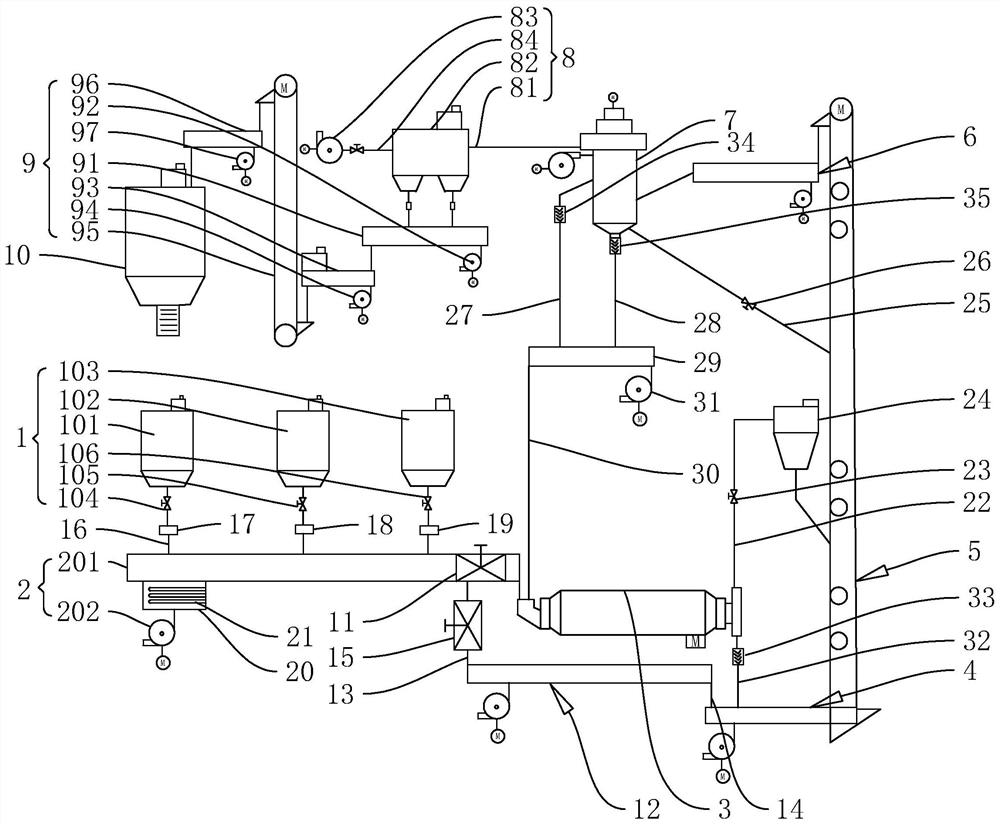

[0042] The following is attached figure 1 The application is described in further detail.

[0043] The embodiment of the present application discloses a superfine fly ash production system. refer to figure 1 , the ultrafine fly ash production system includes a feeding device 1, a first ash conveying device 2, an ash mill 3, a second ash conveying device 4, a lifting device 5, a third ash conveying device 6, and a powder separator connected in sequence 7. The powder collecting device 8, the powder feeding device 9 and the finished product warehouse 10, the lifting device 5 is a vertically arranged closed bucket elevator, and the powder selecting device 7 is a powder selecting machine. A first valve 11 is arranged between the first ash conveying device 2 and the ash mill 3, and a pre-wind separation ash conveying device 12 is arranged between the first ash conveying device 2 and the second ash conveying device 4. The first ash conveying device The outlet of 2 and the inlet of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com