Blanking device for garbage winnowing equipment

A technology of wind separation equipment and blanking device, which is applied in the direction of solid separation, separation of solids from solids by air flow, chemical instruments and methods, etc., which can solve the problems of affecting the wind separation effect, low degree of garbage dispersion, and lack of control of garbage falling Equipment and other problems, to achieve the effect of improving winnowing effect, high winnowing efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

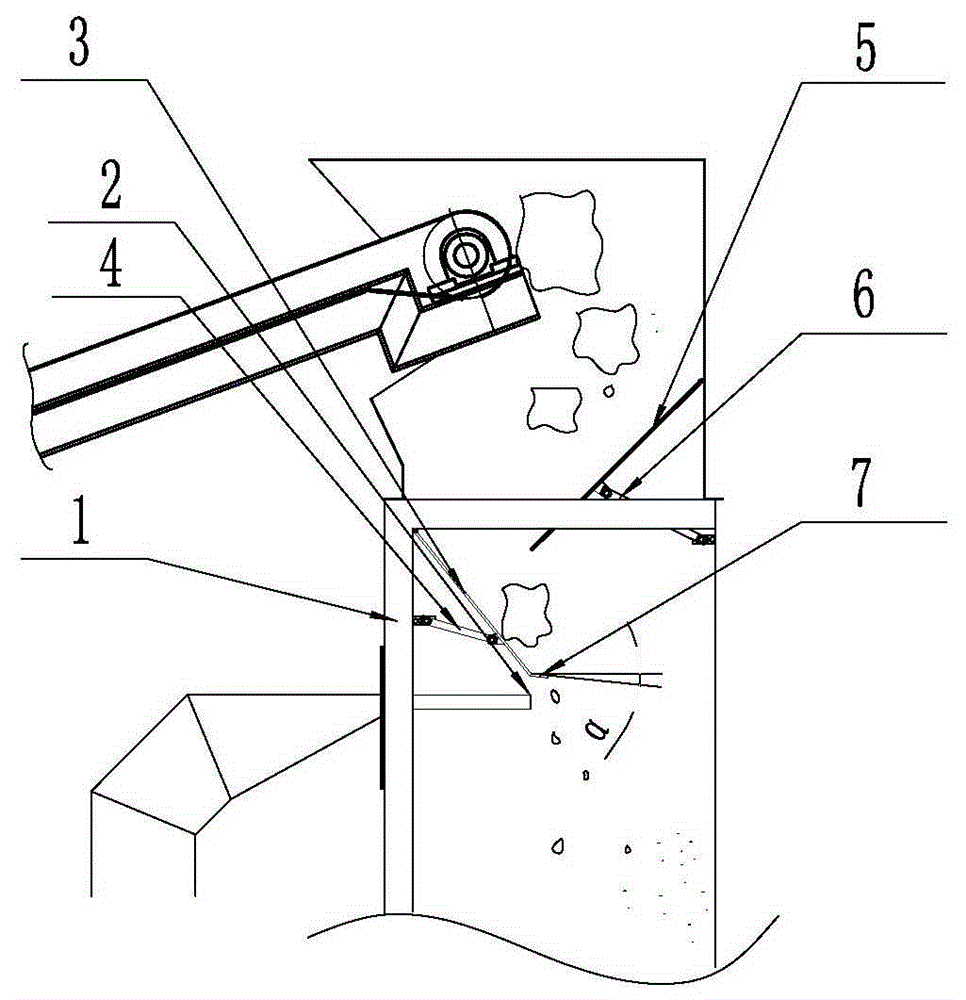

[0017] Description with reference to the accompanying drawings. In the illustrated embodiment, the housing 1 of the garbage winnowing equipment is divided into an upper feeding hopper and a lower blanking chamber. The garbage to be air-selected is sent into the hopper by the conveyor belt, and the outside of the right end of the conveyor belt in the figure is the garbage feeding place. Upper baffle plate 5 is positioned at the below of rubbish feeding place, and its rear end, i.e. the upper right end in the figure, is hinged on the inner wall on the right side of the feed hopper, and its front end, i.e. the lower left end in the figure, is obliquely downward. The lower baffle plate 3 is located below the upper baffle plate 5, its rear end, i.e. the upper left end in the figure, is hinged on the inner wall on the left side of the blanking chamber, and its front end, i.e. the lower right end in the figure, is inclined downward . Comprehend the accompanying drawings as the long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com