Engineering sand making method

An engineering and sandstone technology, applied in the field of engineering sand making, can solve the problems of difficult-sand mica content control, insufficient reliability, complicated process, etc., and achieve the goal of improving the efficiency and accuracy of winnowing, improving accuracy, and improving accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

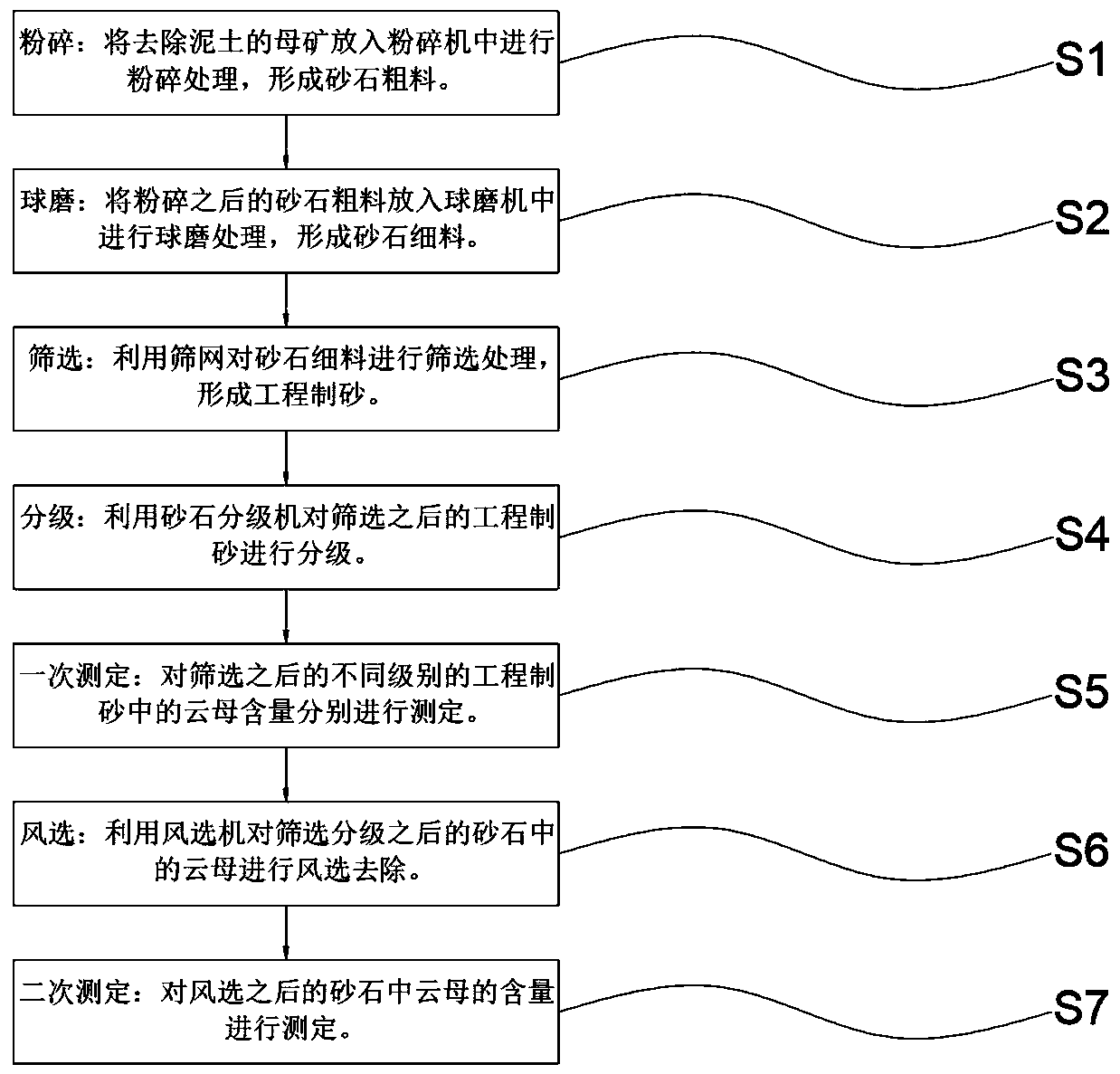

[0032] A kind of method for engineering sand making of the present invention, technological process schematic diagram is as figure 1 shown, including the following steps:

[0033] (1) Crushing: Put the mother ore from which the soil has been removed into a pulverizer for crushing to form coarse sand and gravel; in this step, use the jaw crusher to crush the parent ore to form coarse sand and gravel. The width of the feed port of the machine is 600×400mm, the motor output power of the jaw crusher is 30kW, and the size of the jaw crusher is 1700×1800×1600mm.

[0034] (2) Ball milling: Put the crushed coarse sand and gravel into the ball mill for ball milling to form fine sand and gravel; the cylinder speed of the ball mill is 36r / min, the ball loading capacity of the ball mill is 1.7t, and the motor output of the ball mill The power is 22kW.

[0035] (3) Screening: use screens to screen fine sand and gravel to form engineering sand; in this step, use a vibrating screening mach...

Embodiment 2

[0042] A kind of method for engineering sand making of the present invention, technological process schematic diagram is as figure 1 shown, including the following steps:

[0043](1) Crushing: Put the mother ore from which the soil has been removed into a pulverizer for crushing to form coarse sand and gravel; in this step, use the jaw crusher to crush the parent ore to form coarse sand and gravel. The width of the feed port of the machine is 600×400mm, the motor output power of the jaw crusher is 30kw, and the size of the jaw crusher is 1700×1800×1600mm.

[0044] (2) Ball milling: put the pulverized coarse sand and gravel into a ball mill for ball milling to form fine sand and gravel; in this step, use a ball mill to perform ball milling on the coarse sand and gravel to form fine sand and gravel The rotation speed of the cylinder is 36r / min, the ball loading capacity of the ball mill is 1.7t, and the motor output power of the ball mill is 22kW.

[0045] (3) Screening: use s...

Embodiment 3

[0053] A kind of method for engineering sand making of the present invention, technological process schematic diagram is as figure 1 shown, including the following steps:

[0054] (1) Crushing: Put the mother ore from which the soil has been removed into a pulverizer for crushing to form coarse sand and gravel; in this step, use the jaw crusher to crush the parent ore to form coarse sand and gravel. The width of the feed port of the machine is 600*400mm, the motor output power of the jaw crusher is 30kW, and the size of the jaw crusher is 1700*1800*1600mm.

[0055] (2) Ball milling: put the pulverized coarse sand and gravel into a ball mill for ball milling to form fine sand and gravel; in this step, use a ball mill to perform ball milling on the coarse sand and gravel to form fine sand and gravel The rotation speed of the cylinder is 36r / min, the ball loading capacity of the ball mill is 1.7t, and the motor output power of the ball mill is 22kW.

[0056] (3) Screening: use ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com