Tea-leaf wind selection device

A tea and winnowing technology, which is applied in the field of tea winnowing equipment, can solve problems such as difficulty in distinguishing tea sand and yellow flakes, affecting tea production efficiency, and difficulty in handling semi-finished products, and achieves the effects of improving winnowing efficiency, reasonable design, and unique structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

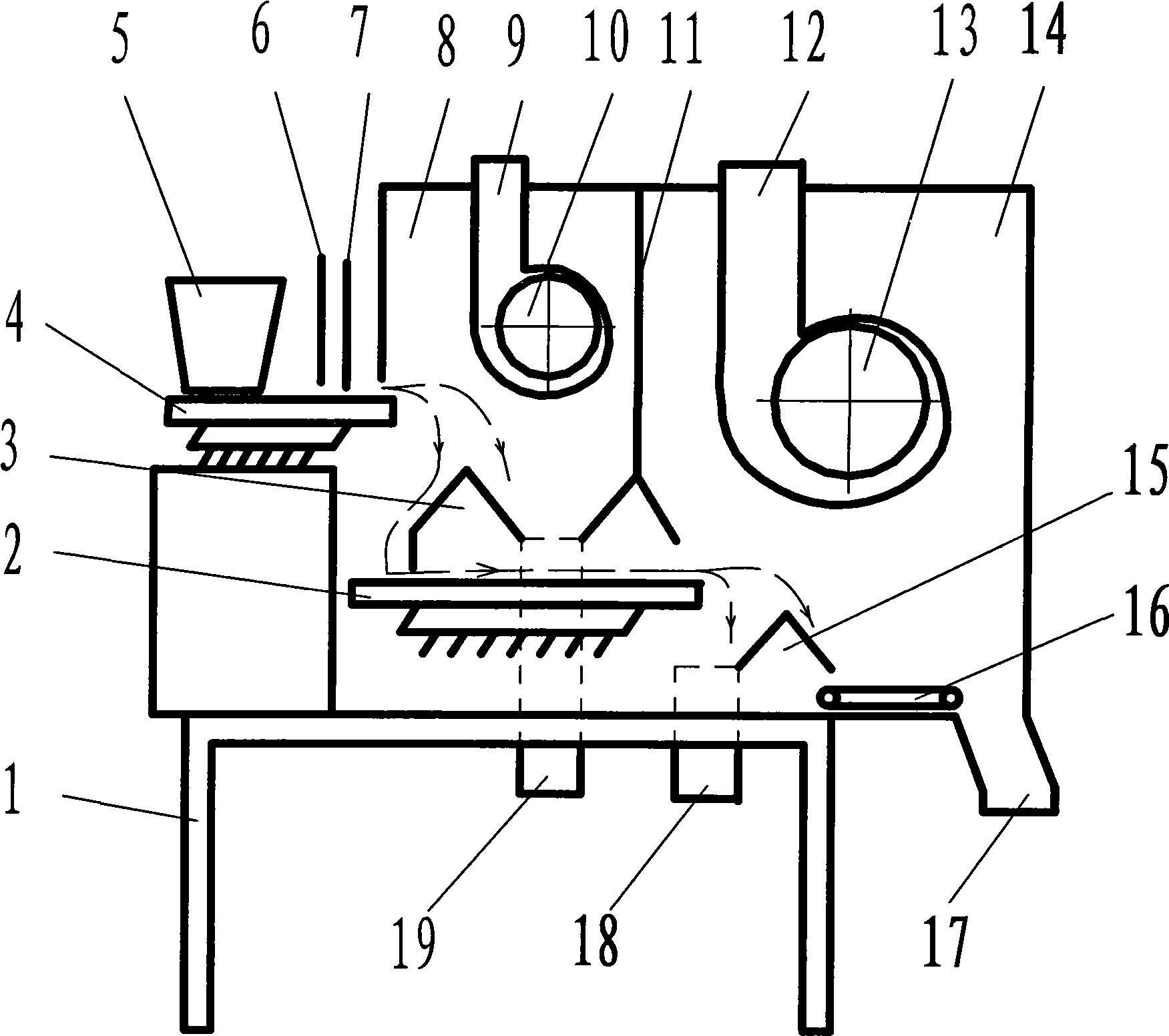

[0008] As shown in the figure, the tea air separation device 1 of the present invention includes a feed hopper 5 and a primary feed vibration tank 4 located below the feed hopper, and is characterized in that: the upper side of the discharge end of the primary feed vibration tank is provided There is a small negative pressure airflow channel for attracting fluffy yellow pieces, the lower side of the discharge end of the primary feeding vibration tank is provided with a secondary vibration tank 2, and the middle part of the secondary vibration tank is provided with a The funnel-shaped yellow flakes collection port 20 is provided between the funnel-shaped fluffy yellow flakes collection port and the primary feeding vibration tank for guiding the heavy tea leaves to fall into the secondary vibration tank, and the fluffy yellow flakes to fall into the funnel-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com