A kind of engineering sand making method

An engineering and sand-gravel technology, applied in the field of engineering sand making, can solve the problems of difficult sand mica content regulation, insufficient reliability, complicated procedures, etc., and achieve the effects of ensuring particle size uniformity, improving accuracy, and improving accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

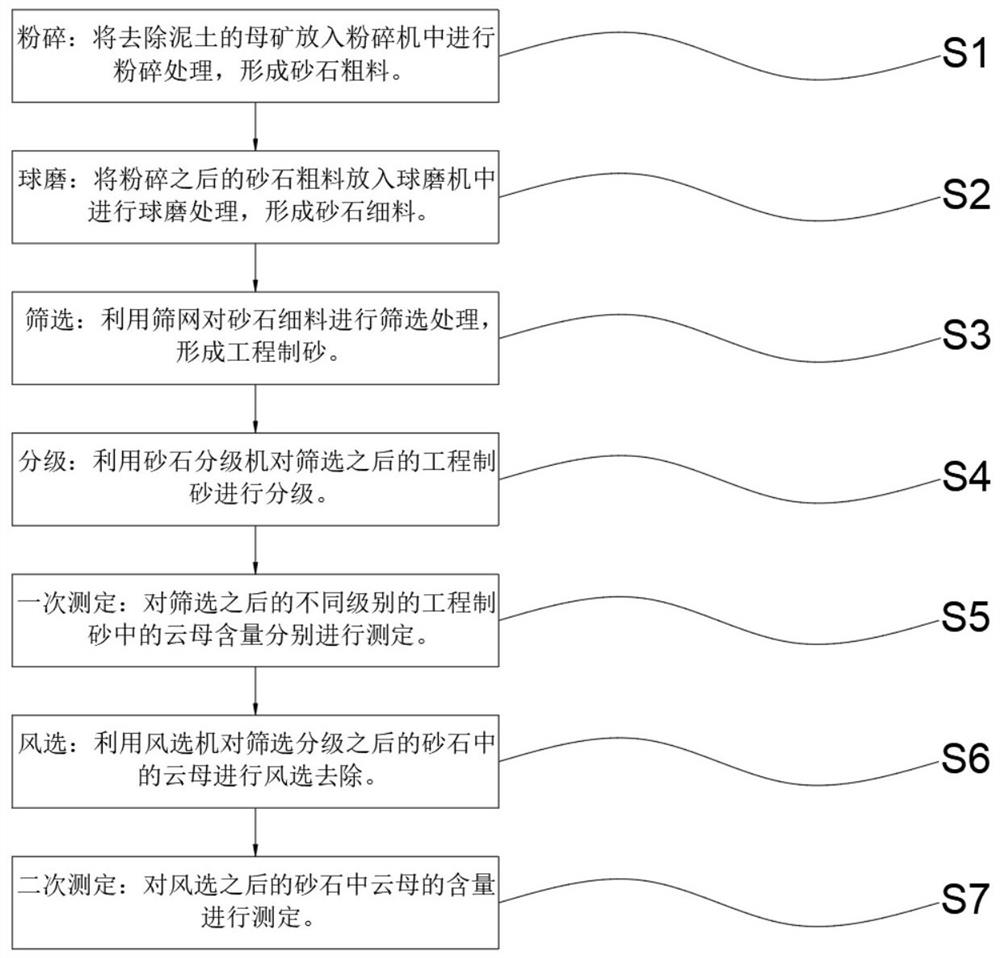

[0032] A kind of method for engineering sand making of the present invention, technological process schematic diagram is as figure 1 shown, including the following steps:

[0033] (1) Crushing: Put the mother ore from which the soil has been removed into a pulverizer for crushing to form coarse sand and gravel; in this step, use the jaw crusher to crush the parent ore to form coarse sand and gravel. The width of the feed port of the machine is 600×400mm, the motor output power of the jaw crusher is 30kW, and the size of the jaw crusher is 1700×1800×1600mm.

[0034] (2) Ball milling: Put the crushed coarse sand and gravel into the ball mill for ball milling to form fine sand and gravel; the cylinder speed of the ball mill is 36r / min, the ball loading capacity of the ball mill is 1.7t, and the motor output of the ball mill The power is 22kW.

[0035] (3) Screening: use screens to screen fine sand and gravel to form engineering sand; in this step, use a vibrating screening mach...

Embodiment 2

[0042] A kind of method for engineering sand making of the present invention, technological process schematic diagram is as figure 1 shown, including the following steps:

[0043](1) Crushing: Put the mother ore from which the soil has been removed into a pulverizer for crushing to form coarse sand and gravel; in this step, use the jaw crusher to crush the parent ore to form coarse sand and gravel. The width of the feed port of the machine is 600×400mm, the motor output power of the jaw crusher is 30kw, and the size of the jaw crusher is 1700×1800×1600mm.

[0044] (2) Ball milling: put the pulverized coarse sand and gravel into a ball mill for ball milling to form fine sand and gravel; in this step, use a ball mill to perform ball milling on the coarse sand and gravel to form fine sand and gravel The rotation speed of the cylinder is 36r / min, the ball loading capacity of the ball mill is 1.7t, and the motor output power of the ball mill is 22kW.

[0045] (3) Screening: use s...

Embodiment 3

[0053] A kind of method for engineering sand making of the present invention, technological process schematic diagram is as figure 1 shown, including the following steps:

[0054] (1) Crushing: Put the mother ore from which the soil has been removed into a pulverizer for crushing to form coarse sand and gravel; in this step, use the jaw crusher to crush the parent ore to form coarse sand and gravel. The width of the feed port of the machine is 600*400mm, the motor output power of the jaw crusher is 30kW, and the size of the jaw crusher is 1700*1800*1600mm.

[0055] (2) Ball milling: put the pulverized coarse sand and gravel into a ball mill for ball milling to form fine sand and gravel; in this step, use a ball mill to perform ball milling on the coarse sand and gravel to form fine sand and gravel The rotation speed of the cylinder is 36r / min, the ball loading capacity of the ball mill is 1.7t, and the motor output power of the ball mill is 22kW.

[0056] (3) Screening: use ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com