A new type of absorber and its absorption refrigeration system

An absorber and a new type of technology, which are applied in the field of new absorbers and their absorption refrigeration systems, can solve the problems of low utilization rate of waste heat and achieve the effects of reducing costs, improving absorption efficiency, and improving utilization rates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

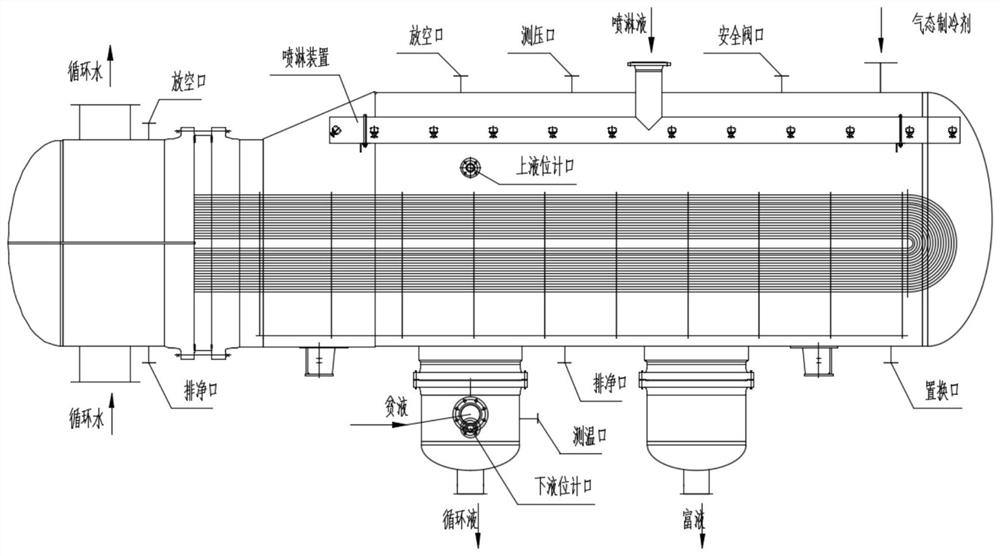

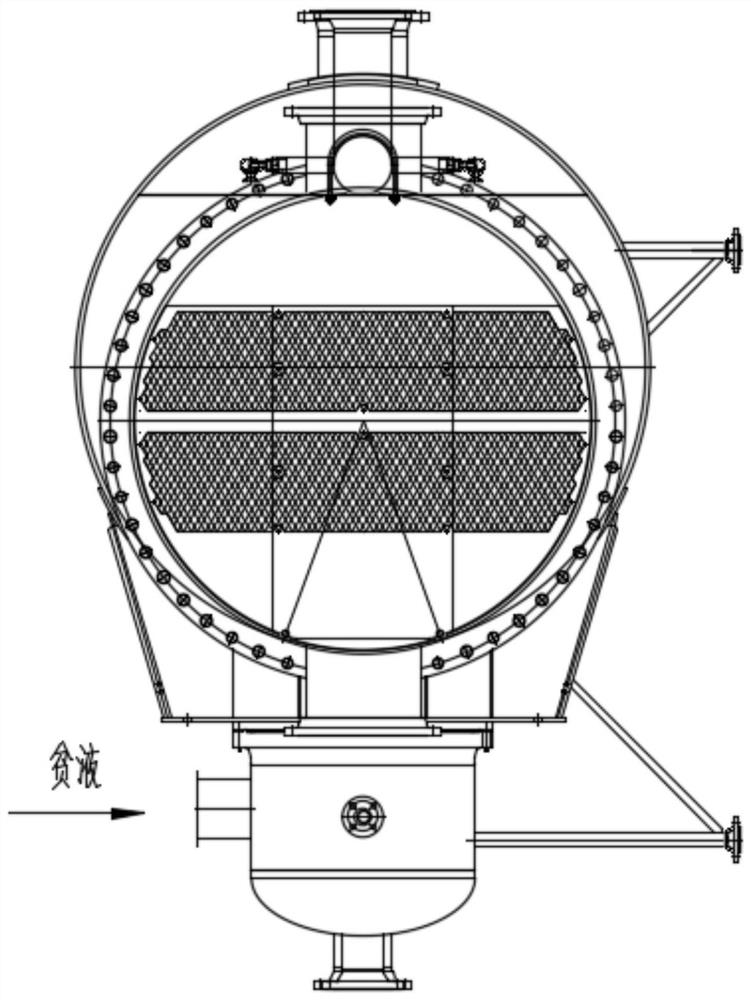

[0030] The application will be described in further detail below in conjunction with the accompanying drawings. It is necessary to point out that the following specific embodiments are only used to further illustrate the application, and should not be construed as limiting the protection scope of the application. Those skilled in the art can The above application content makes some non-essential improvements and adjustments to this application.

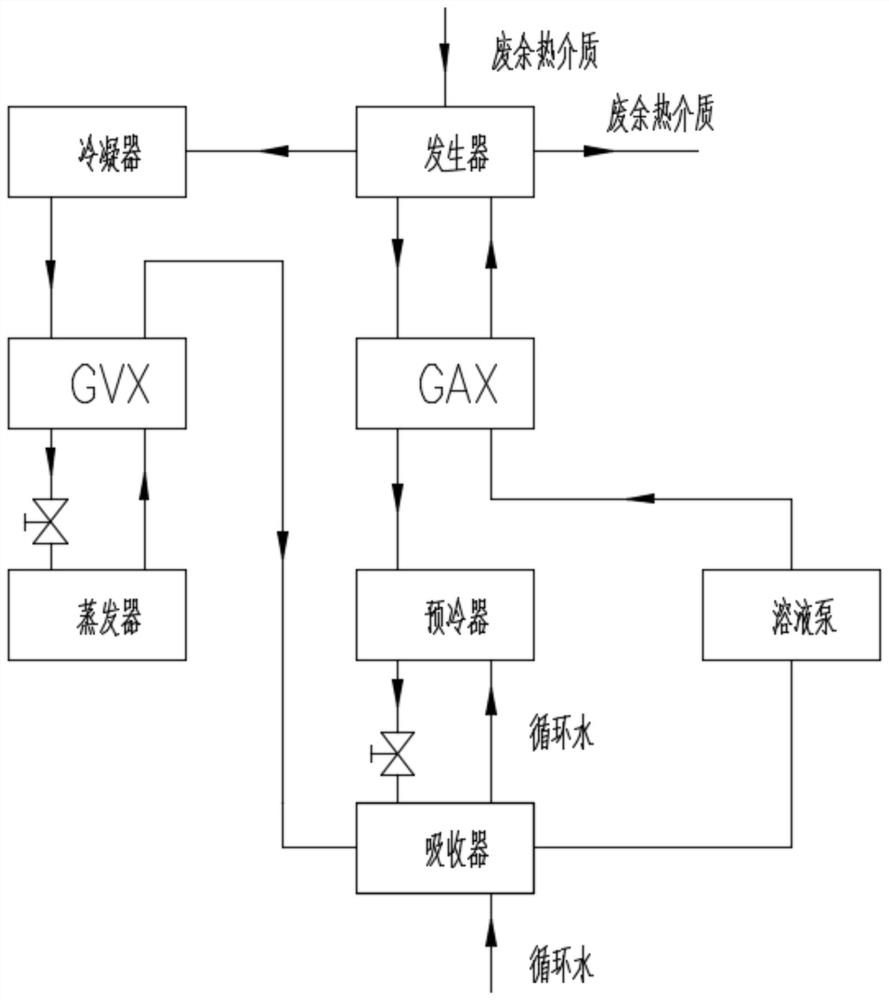

[0031] like Figure 7 As shown, the absorption refrigeration system in this embodiment includes an evaporator 300, a condenser 200, a generator 100, a solution pump 400 and a new type of absorber. The generator 100 uses waste heat medium as a heating source, and the new type of absorber uses a The waste heat medium discharged from the outlet of the heat source of the generator 100 is used as a heat source for preheating the rich liquid discharged from the new absorber. On the one hand, it can improve the utilization rate of the waste ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com