Flow distribution device for light alloy casting and rolling

A light alloy casting and rolling technology, which is applied in the field of light alloy casting and rolling distribution devices, can solve the problems of affecting the performance of castings, prone to pores, uneven distribution of metal melt, etc., achieves simple structure, realizes uniform distribution, and promotes uniform solidification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

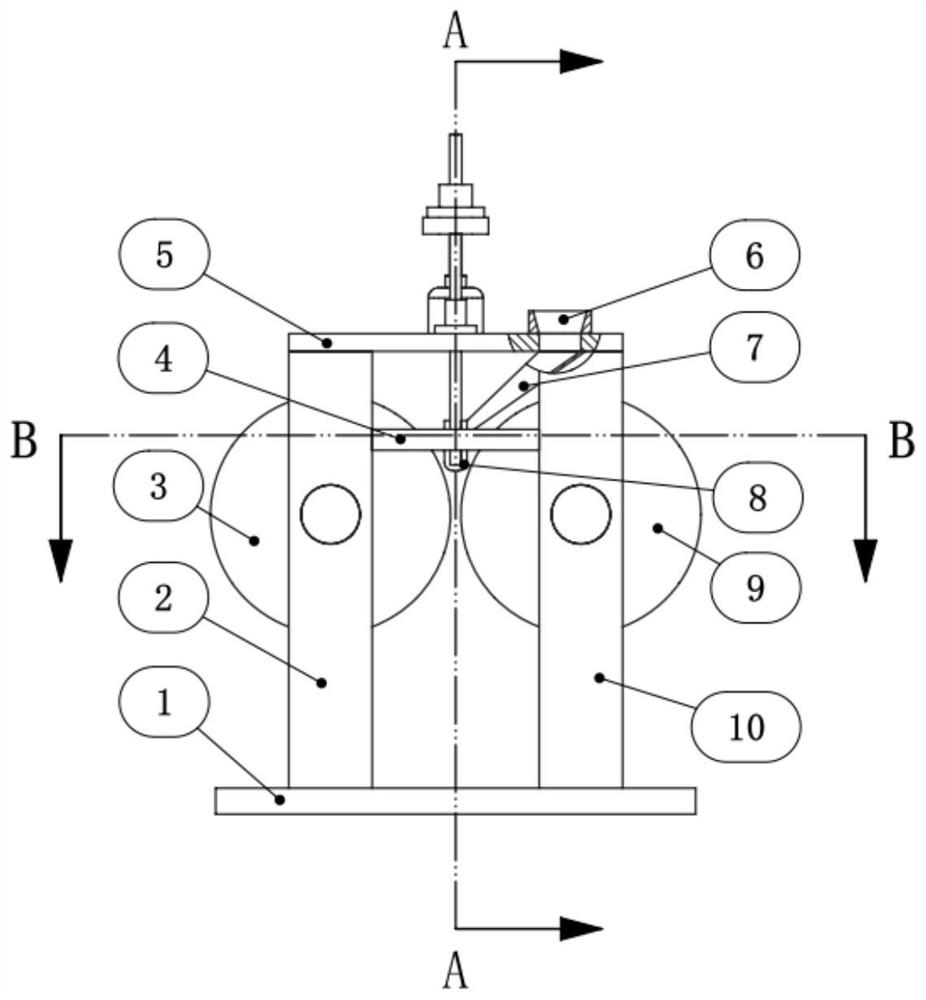

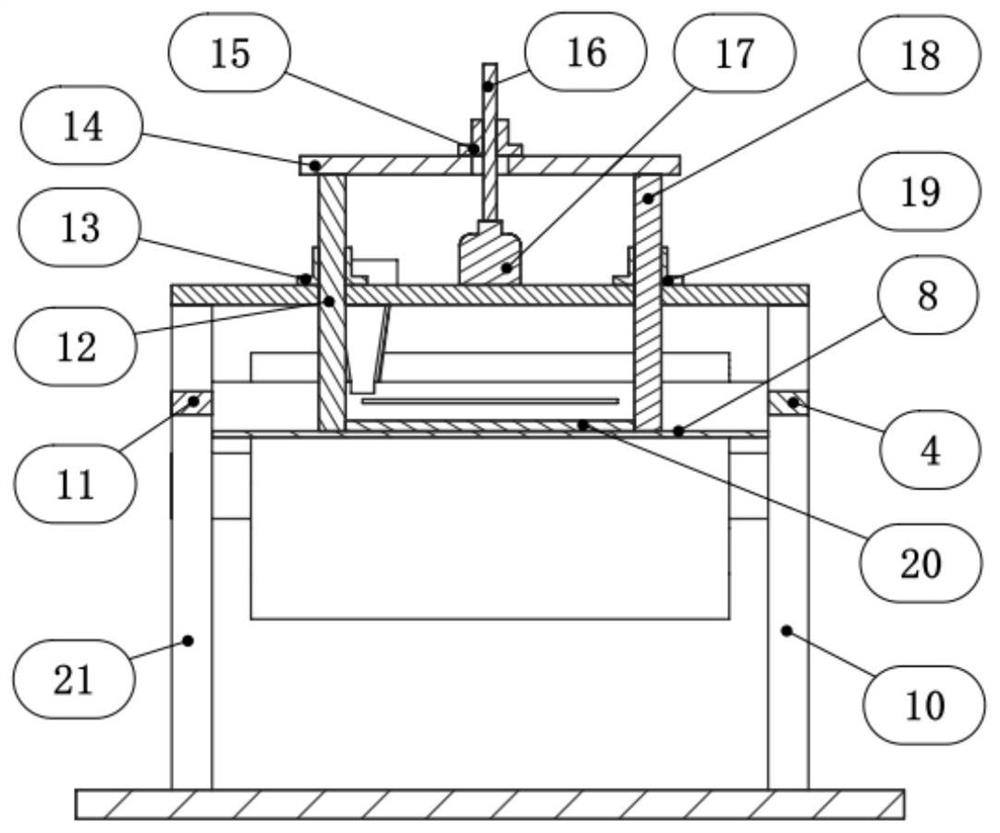

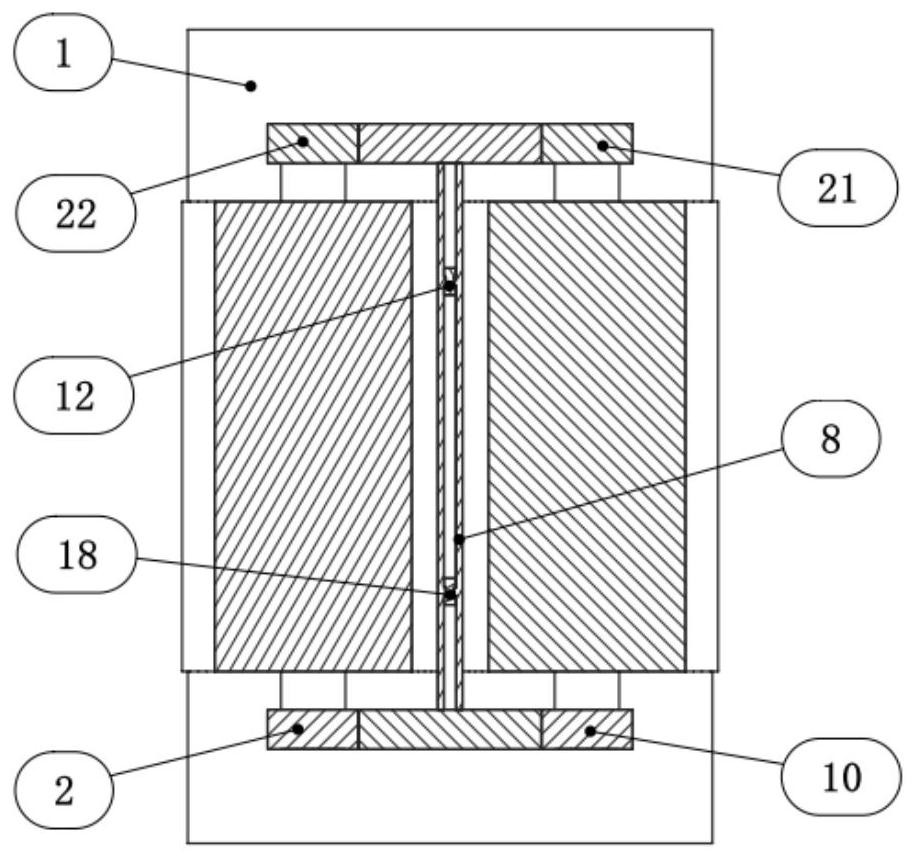

[0029] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS In conjunction with the drawings, aluminum alloy 6061 is selected as the raw material. The device consists of base 1, left roll front column 2, left roll 3, front fixed beam 4 of molten metal tank, upper fixed plate 5, sprue cup 6, inclined runner of molten metal 7, molten metal tank 8, right Roller 9, Right Roller Front Column 10, Metal Melt Tank Rear Fixed Beam 11, Metal Melt Support Plate Rear Guide Column 12, Metal Melt Support Plate Rear Guide Column Guide Bushing 13, Metal Melt Support Plate Guide Column Fixed Connection Plate 14. Upper fixing nut 15, adjusting screw 16, motor 17, metal melt supporting plate leading column 18, metal melting supporting plate leading column guide sleeve 19, metal melting supporting plate 20, right roll rear column 21, left roll rear Column 22 forms.

[0030] The two ends of left roll 3 are contained in the inner hole of left roll front column 2 and left roll rear column 22, and left...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com