Large-space dirt removal device with gas-sound complex fields uniformly distributed and dirt removal method of large-space dirt removal device

A compound field and large space technology, applied in the direction of combustion method, removal of solid residue, treatment of combustion products, etc., can solve the problems of high flue gas dew point, limited sound energy, insufficient rapping force, etc., and achieve uniform distribution effect improvement , sound energy enhancement, promote the effect of descaling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

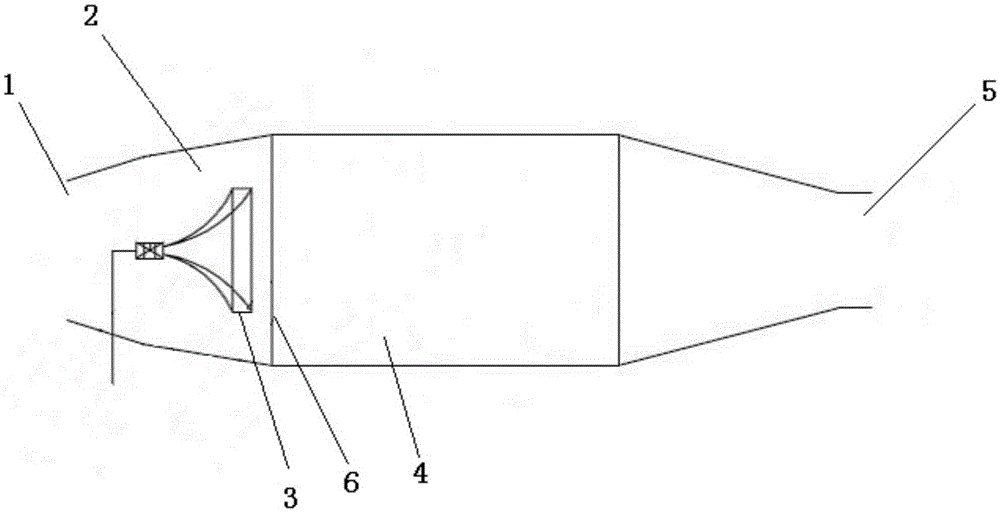

[0042] Such as figure 1 As shown, it is a schematic diagram of a large-space descaling device with an aeroacoustic composite field uniform distribution in this embodiment, including a device inlet 1, an aeroacoustic uniform field arrangement space 2, a sonic soot blowing device 3, a descaling space 4 and a device outlet 5, among which The setting method is to set the aero-acoustic equalizing arrangement space 2 behind the device entrance 1, install the sonic soot blowing device 3 in the aero-acoustic equalizing arrangement space 2, set the descaling space 4 after the aero-acoustic equalizing arrangement space 2, and set the descaling space 4 The outlet 5 of the device is installed in the rear; an aeroacoustic deflector 6 is arranged between the aeroacoustic equalization space 2 and the descaling space 4, and the sounding direction of the sonic soot blowing device 3 faces the aeroacoustic deflector 6. Depend on figure 1 It can be seen that the aeroacoustic averaging arrangemen...

Embodiment 2

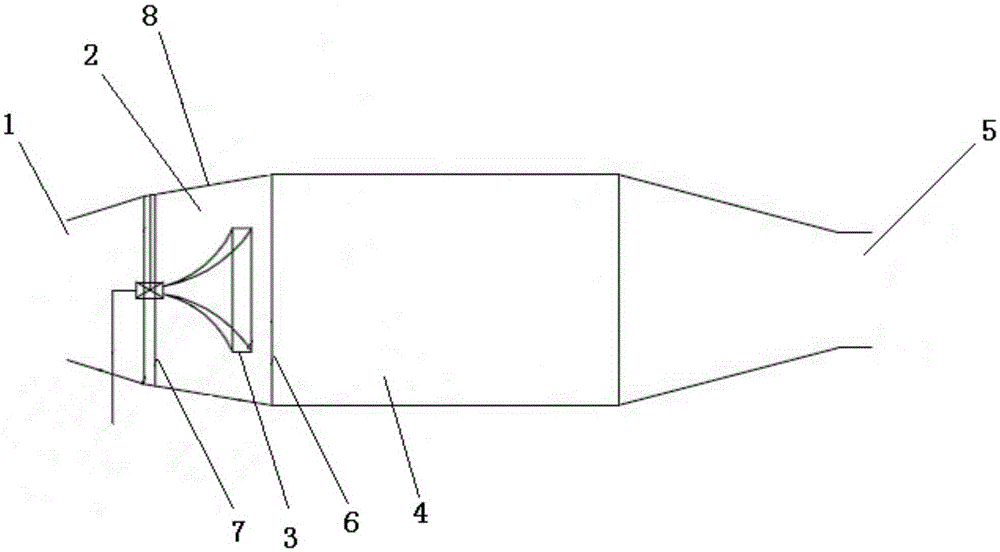

[0044] Such as figure 2 As shown, it is a further improvement on the basis of Example 1, in which an air inlet plate 7 is provided at the entrance 1 of the device, and the aeroacoustic homogenization space 2 is the air inlet plate 7, the aeroacoustic deflector 6 and the space between them. The space enclosed by the space wall 8; in order to better play the uniform distribution and reverberation effect of the aeroacoustic average field layout space, the section of the aeroacoustic average field layout space 2 along the expansion direction is set to be an isosceles trapezoid in this embodiment , wherein the space wall 8 between the aeroacoustic deflector 6 and the air inlet plate 7 is used as the waist of the isosceles trapezoidal section, the air inlet plate 7 and the aeroacoustic deflector 6 are used as the bottom of the isosceles trapezoid, and the aeroacoustic deflector 6. The corresponding side length ratio of the section formed by the air inlet plate 7 and the space wall ...

Embodiment 3

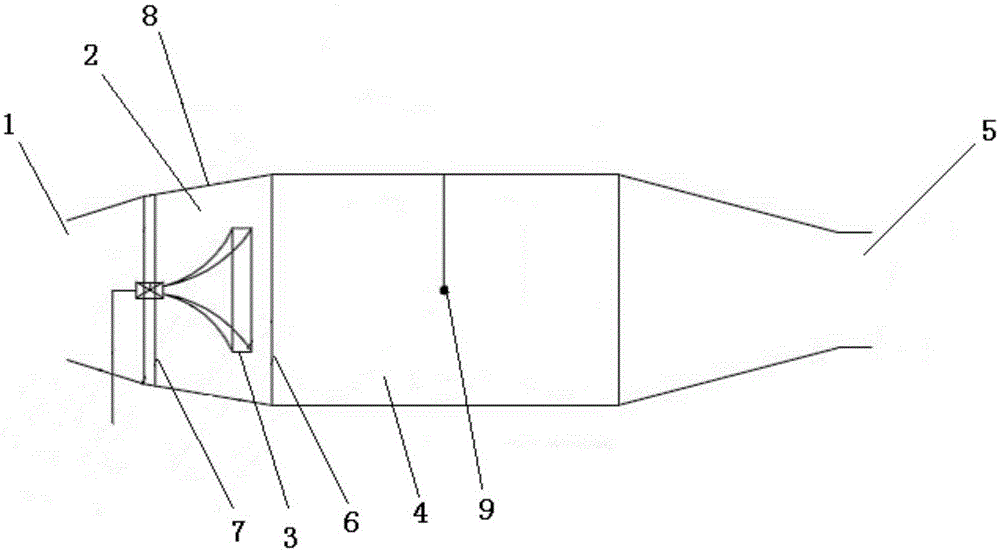

[0047] Such as image 3 As shown, as a further improvement on the basis of Example 2, an acoustic sensor 9 is provided in the descaling space 4, which can effectively monitor the sound waves passing through the descaling space 4, and timely adjust the sound wave index according to the monitoring results.

[0048] Such as Figure 4 As shown, an easy-to-fouling device 10 is also provided in the descaling space 4. The easy-to-fouling device can be installed according to needs during actual use, and can be a heat exchanger or a dust collector or other equipment. The sonic soot blowing device 3 is connected by a controller (11), a sound conduit, a sound generator and a gas pipeline, wherein the gas pipeline is used to transport the working gas of the sonic soot blowing device, and the controller (11) is used to control the sound generator During the running process, the acoustic sensor 9 is connected with the controller 11, so that the acoustic sensor 9 can feed back the sensed ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com