A load balancing sliding bearing

A sliding bearing and bearing technology, applied in the direction of sliding contact bearings, shafts and bearings, bearing components, etc., can solve the problem of unbalanced force on the support pad, achieve balanced force, compact structure design, and solve the problem of temperature deviation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

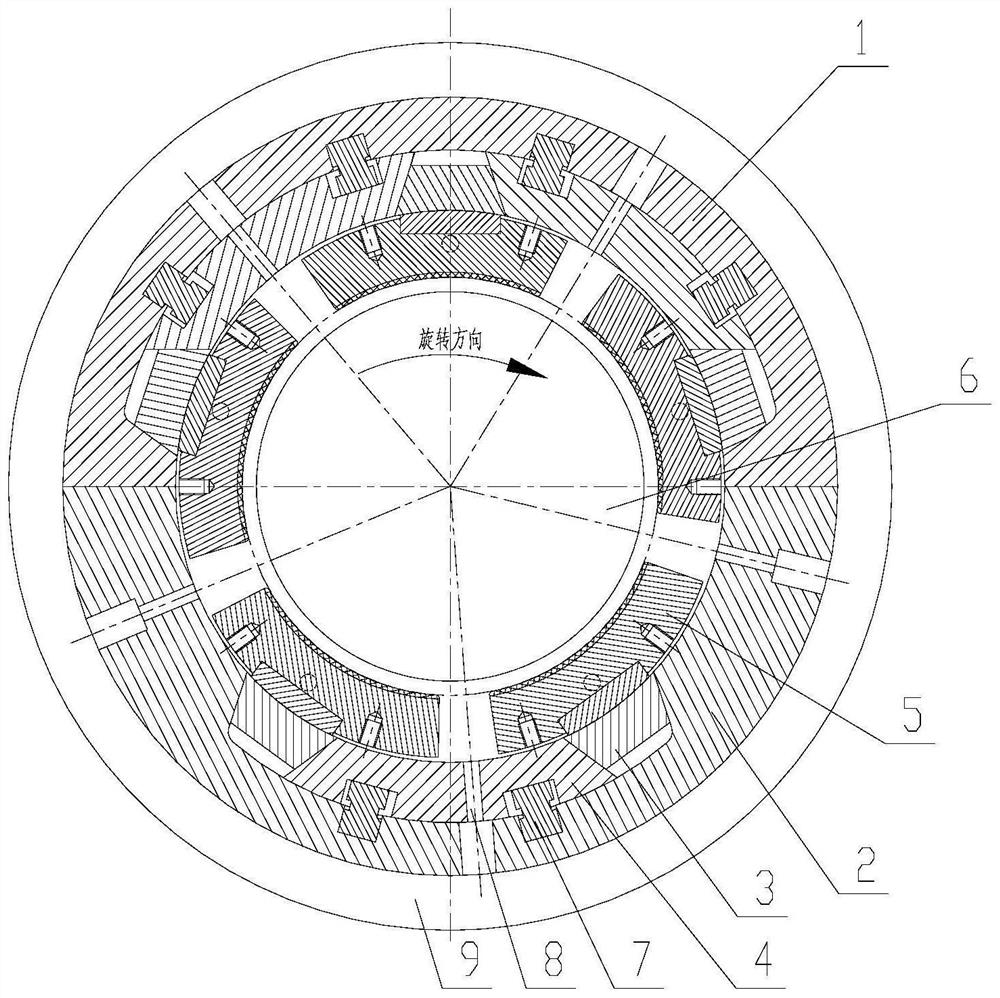

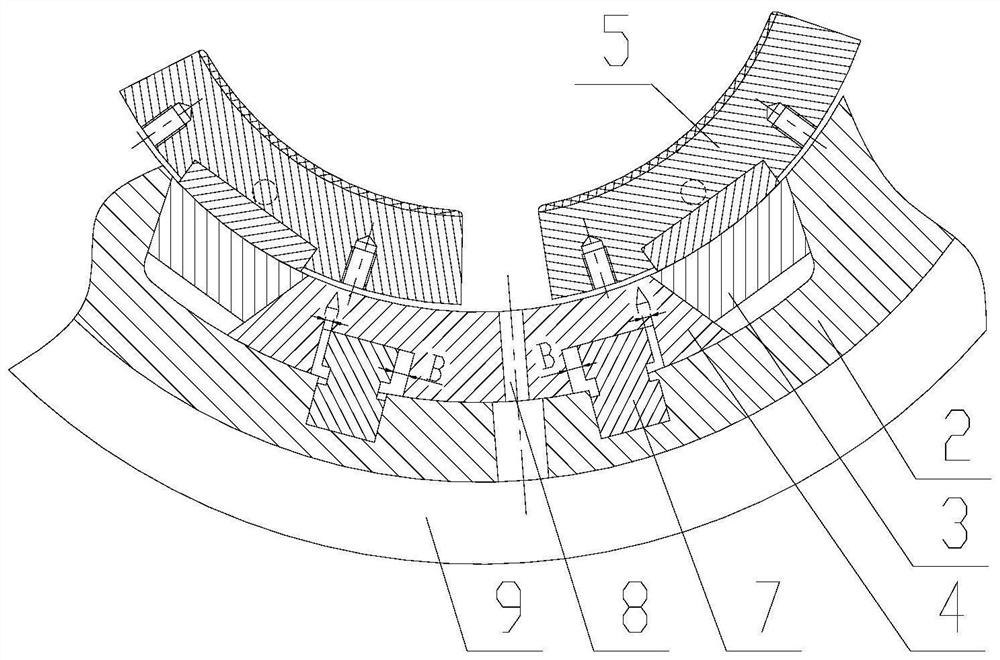

[0037] This embodiment is basically as follows: Figure 1 The embodiment provides a uniform load sliding bearing for balancing the radial force of the rotor; The sliding bearing is divided into four layers from inside to outside, including the outermost bearing shell body, the innermost supporting pad 5 and the load sharing adjustment mechanism arranged between the outer bearing shell body and the supporting pad 5. The bearing shell body provided in this embodiment includes the upper half 1 and the lower half 2 of the bearing shell body. The upper half 1 and the lower half 2 of the bearing shell body are in surface contact and realize fixed and removable connection, and the whole bearing shell body is in a ring structure after assembly, An installation space for installing the journal 6 and each support pad 5 is formed in the annular structure, so that each support pad 5 is evenly arranged around the journal 6. The design purpose of the load sharing adjustment mechanism is to solve...

Embodiment 2

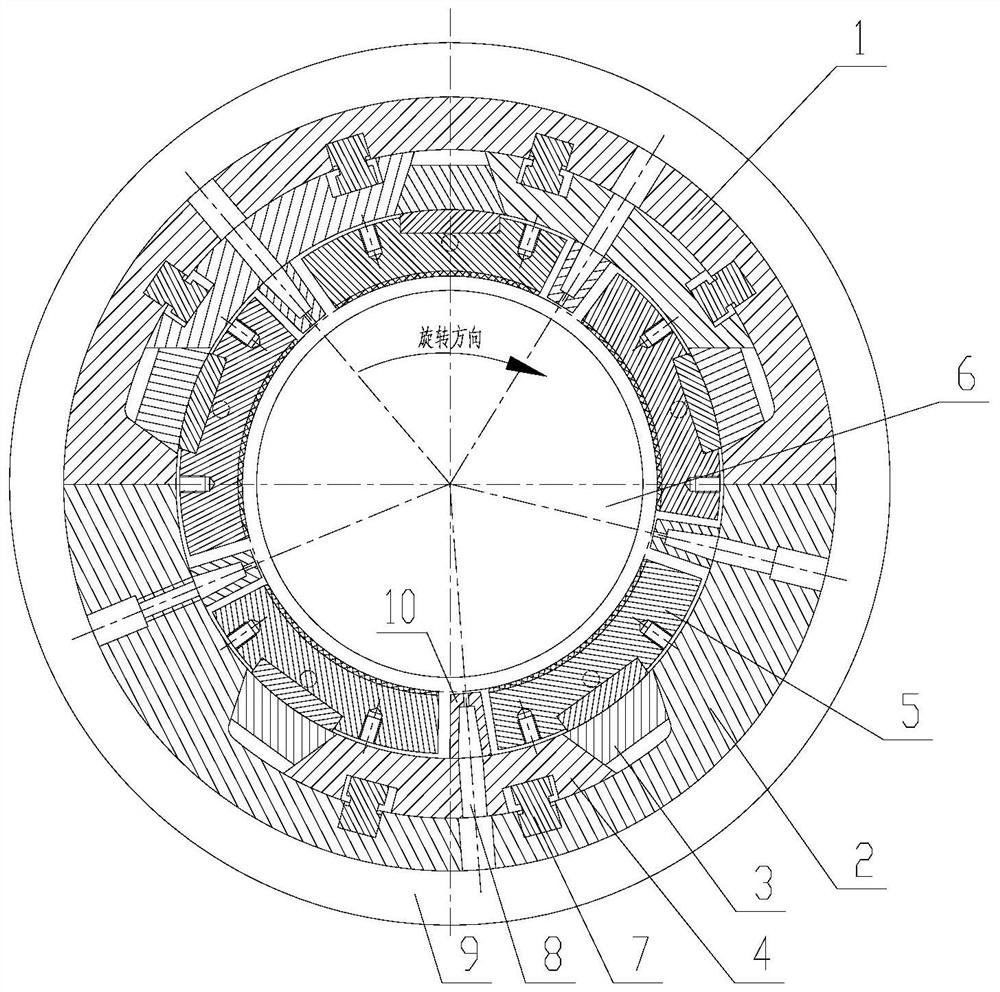

[0048] Embodiment 2 is basically the same as embodiment 1, with the difference that: Figure 3 and Figure 4 As shown in the figure: as a preferred embodiment of embodiment 1, a spray block 10 for injecting oil into the bearing is installed on the rotating load sharing block 4 in this embodiment, the oil inlet of the spray block 10 is connected with the oil inlet hole 8 of the rotating load sharing block 4, and the oil outlet hole of the spray block 10 corresponds to the support pad 5.

[0049] To sum up, the uniform load sliding bearing in this embodiment has simple structure and fast assembly speed. Combined with the oil inlet ring groove 9 on the bearing shell body, the oil inlet hole 8 on the rotating uniform load block 4 and the spray block 10, when the bearing is in service, the lubricating oil can enter the spray block 10 through the oil inlet ring groove 9 on the bearing shell body, the bearing shell body and the oil inlet hole 8 of the rotating uniform load block 4, and dir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com