Surface microstructural array with self-transportation performance and forming method thereof

A microstructure array and molding method technology, applied in 3D object support structures, manufacturing tools, additive manufacturing, etc., can solve the problems of low molding efficiency, difficulty in forming microstructures on functional surfaces, and low condensation efficiency on superhydrophobic functional surfaces. The effect of reducing molding time, improving molding accuracy and molding quality, and improving condensation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

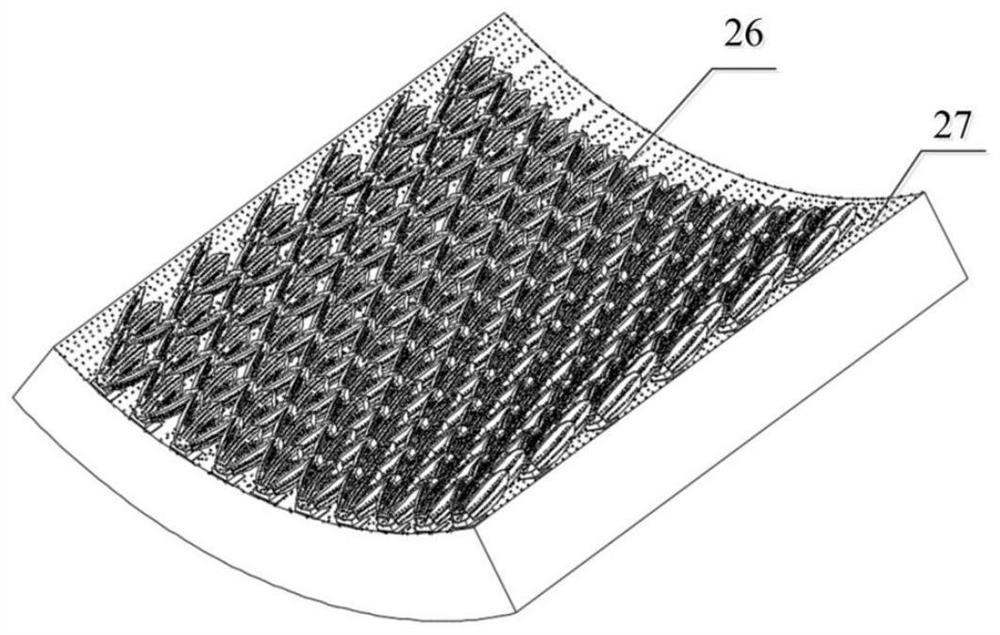

[0021] See attached Figure 1~4 , the single microstructure of the self-transporting surface microstructure array is a shark scale imitation structure 28, which is a triangular protrusion, made of photosensitive resin 7, with a total length of 13.6 µm in the transverse direction and a total length of 10.2 µm in the longitudinal direction , and the total length is 6.2µm; the lateral distance between two adjacent microstructures is 7.8µm, and the vertical distance is 4.2µm; the tail of the raised microstructure is inclined upward about 26° relative to the inner wall of the pipe or the surface of the device; on the surface of the microstructure, Nanoparticles 17 are distributed to form a micro / nano composite structure with the sharkskin structure 28 ; a plurality of the above composite structures are evenly distributed on the target surface 27 of the molded part to form a surface microstructure array 26 .

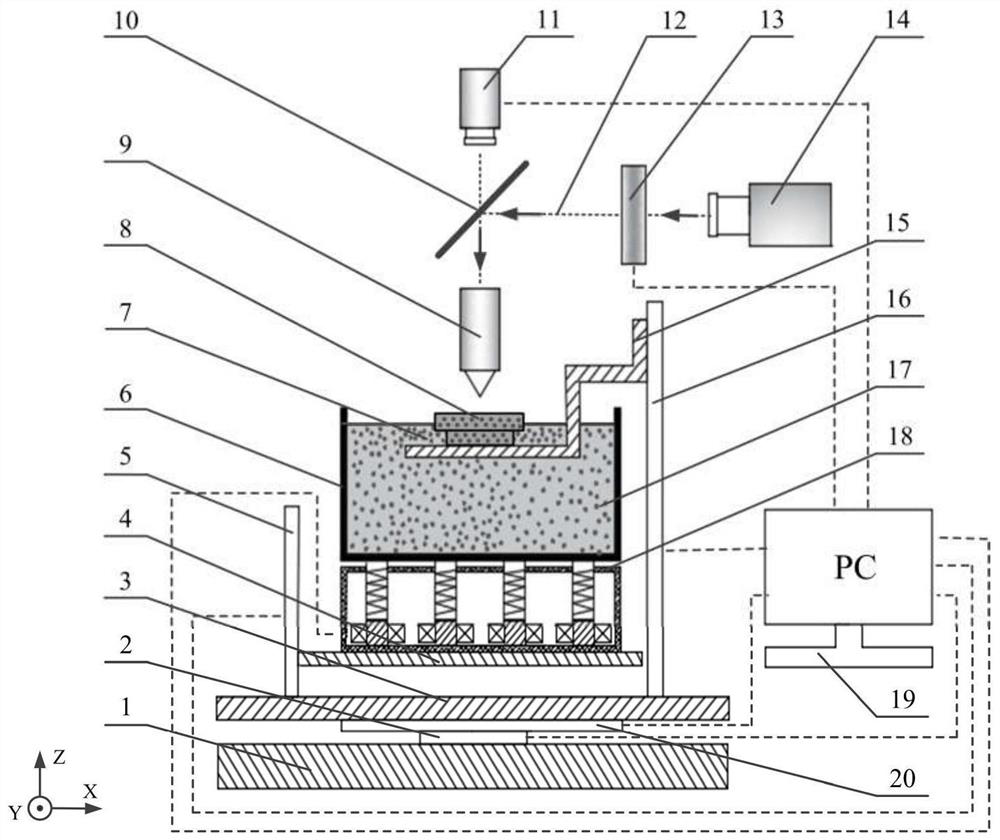

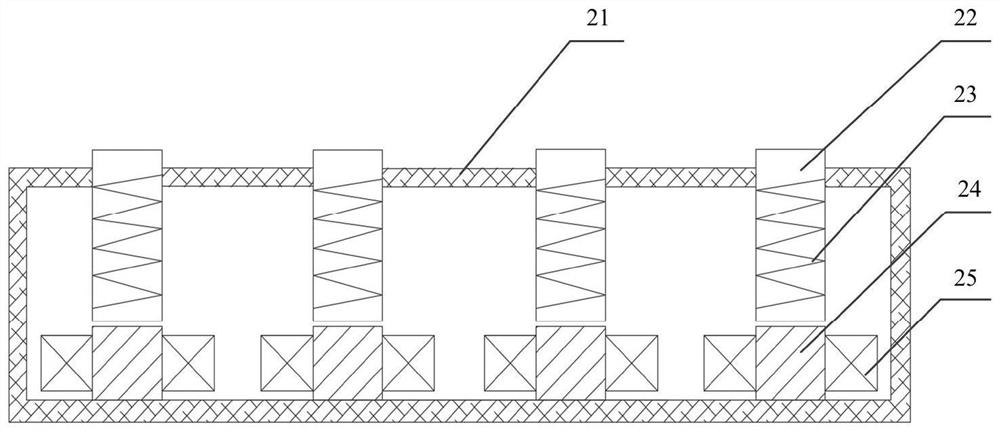

[0022] The forming method of the surface microstructure array 26 with self...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com